Ground Screw Technology: Revolutionizing Foundation Solutions Across Industries

In the rapidly evolving landscape of modern construction and infrastructure development, the ground screw has emerged as a transformative foundational solution, offering unparalleled efficiency, environmental sustainability, and versatility compared to traditional concrete systems. This innovative technology, essentially a large, high-strength steel helical anchor, is meticulously engineered to be driven directly into the ground, providing robust support without the need for extensive excavation, pouring, or curing times. The shift towards ground screw technology reflects a broader industry trend focusing on rapid deployment, reduced environmental impact, and enhanced project cost-effectiveness. Its adoption is increasingly prevalent in sectors ranging from renewable energy, particularly solar farms, to telecommunications infrastructure, modular building construction, and even residential applications like decking and fencing. The inherent design of the ground screw allows for superior load distribution and exceptional resistance to uplift, compression, and lateral forces, making it an ideal choice for a diverse array of structural needs. This comprehensive guide delves into the intricate details of ground screw technology, exploring its manufacturing excellence, precise technical parameters, wide-ranging applications, and the strategic advantages it confers upon contemporary construction projects. We will also examine the critical factors for selecting optimal solutions, highlight real-world success stories, and address common inquiries to underscore why ground screws are quickly becoming the foundation of choice for a sustainable future.

The evolution of foundation solutions has seen a continuous pursuit of methods that minimize disruption while maximizing structural integrity. Traditional concrete foundations, while robust, often involve significant site preparation, including excavation, spoil removal, and lengthy curing periods, all of which contribute to increased project timelines, labor costs, and environmental footprint. In contrast, the direct installation of a ground screw minimizes these challenges, allowing for immediate construction upon installation. This fundamental advantage has propelled the ground screw from a niche product to a mainstream foundational element. Market analyses consistently show a robust growth trajectory for the ground screw market, driven by global initiatives in renewable energy, burgeoning demand for modular and temporary structures, and the increasing emphasis on sustainable building practices. Projections indicate a substantial compound annual growth rate (CAGR) for the ground screw market over the next decade, with specific segments like solar mounting systems and prefabricated housing leading the charge. This growth is further fueled by technological advancements in screw design, installation equipment, and material science, leading to even more resilient and adaptable ground screw solutions. As construction practices continue to prioritize speed, efficiency, and ecological responsibility, the role of the ground screw as a foundational technology is set to expand exponentially, solidifying its position as a cornerstone of modern, sustainable development.

The Engineering Excellence: Ground Screw Manufacturing Process and Quality Assurance

The superior performance of a ground screw is fundamentally rooted in its meticulous manufacturing process, beginning with the selection of high-grade materials and extending through advanced fabrication techniques and rigorous quality control. Typically, ground screws are manufactured from structural steel, with common grades including Q235B (equivalent to ASTM A36 or S235JR in European standards) or Q345B (equivalent to ASTM A572 Grade 50 or S355JR). These steel grades are chosen for their excellent yield strength, tensile strength, and weldability, ensuring the finished product can withstand significant static and dynamic loads without deformation. A critical aspect of the material specification is the hot-dip galvanization process, which provides exceptional corrosion resistance. Adhering to standards like ISO 1461 (Hot-dip galvanized coatings on fabricated iron and steel articles), the steel is immersed in a bath of molten zinc at approximately 450°C. This process forms a metallurgical bond between the zinc and steel, creating a durable, multi-layered coating that is significantly more effective against corrosion than paint or electro-plating. The minimum average coating thickness for ground screws is typically 85 microns, ensuring a lifespan often exceeding 50 years, even in challenging soil conditions or coastal environments. This robust anti-corrosion treatment is vital for applications in industries such as petrochemical, where exposure to corrosive elements is common, or in metallurgy and water supply/drainage systems where long-term durability is paramount.

The manufacturing journey of a ground screw involves several precision-engineered steps. It begins with the cutting of steel pipes and plates to precise dimensions using automated laser or plasma cutting machines, ensuring high accuracy and minimal material waste. This is followed by the forming of the helical flights (the spiral blades) from steel plates, a process that requires specialized machinery to achieve the correct helix angle and pitch, which are crucial for optimal penetration and load-bearing capacity. These helical flights are then expertly welded onto the central steel shaft. Advanced welding techniques, often robotic or semi-automatic, are employed to ensure consistent, high-integrity welds that meet stringent structural standards, such as EN 1090 for structural steel components. Post-welding, the ground screws undergo thorough inspection for weld integrity, dimensional accuracy, and surface finish before proceeding to the hot-dip galvanization stage. After galvanization, each ground screw is subjected to a final round of quality checks, including visual inspection for coating uniformity, thickness measurement using magnetic induction gauges, and often, non-destructive testing (NDT) like ultrasonic testing or dye penetrant inspection for critical welds. Adherence to international inspection standards, such as ISO 9001 for quality management systems and ISO 17025 for testing laboratories, guarantees that every ground screw leaving the factory meets the highest performance and durability benchmarks. This rigorous process not only ensures compliance with industry regulations like ANSI for structural components but also significantly extends the product's service life, making it a reliable and cost-effective solution for various applications, including those requiring robust ground screw anchors.

Unveiling Technical Parameters and Performance Metrics of Ground Screws

Understanding the technical parameters and performance metrics of ground screw foundations is paramount for engineers, project managers, and procurement specialists. These parameters dictate the suitability of a specific ground screw for a given application and its ability to withstand the anticipated loads and environmental conditions. The primary performance metrics include axial compression load capacity, tension (uplift) load capacity, and lateral load resistance. Axial compression refers to the downward force the screw can bear, typically ranging from 10 kN to over 200 kN depending on screw dimensions, soil type, and installation depth. Tension capacity, crucial for structures susceptible to wind uplift or seismic forces, relies on the friction and bearing resistance of the helical flights against the soil, often ranging from 5 kN to 150 kN. Lateral load resistance, important for structures subjected to horizontal forces like wind or seismic activity, is influenced by the shaft diameter, embedded length, and soil stiffness. Factors influencing these capacities are manifold: soil type (e.g., sandy, clay, silty, rocky), soil density, moisture content, and the presence of groundwater. The geometry of the ground screw itself—including shaft diameter (e.g., 60mm, 76mm, 89mm, 114mm), length (e.g., 800mm to 4000mm+), number of helical flights, and flight diameter (e.g., 200mm to 350mm)—directly impacts its load-bearing capabilities. For instance, a larger shaft diameter provides greater bending resistance, while more or larger helical flights enhance pull-out and compression resistance.

Installation torque is another critical parameter, serving as an indicator of the soil's resistance and often correlating directly with the ultimate load capacity. Professional installation teams utilize specialized hydraulic drivers, often employing a ground screw drill, which monitor installation torque to ensure the screw reaches its designed bearing stratum and achieves optimal embedment. The data from such installations, combined with geotechnical surveys (e.g., Cone Penetration Tests - CPT, Standard Penetration Tests - SPT), allows for precise load capacity calculations. Many manufacturers provide a ground screw calculator or software that integrates these geotechnical parameters with screw dimensions to predict performance, ensuring accurate foundation design. Furthermore, the material's yield strength and tensile strength, coupled with the hot-dip galvanized coating thickness and uniformity (ISO 1461), determine the ground screw's long-term durability and resistance to corrosion, ensuring a service life of 20 to 50+ years. The integrity of welding points, typically assessed through non-destructive testing (NDT), also plays a crucial role in overall structural integrity. Below is a detailed table outlining typical specifications for various ground screw types, demonstrating the range and versatility of these engineering components. These specifications are crucial for selecting appropriate ground screw anchors for specific project requirements, ensuring safety, stability, and longevity of the constructed assets.

Typical Ground Screw Specifications and Performance Data

Diverse Applications and Strategic Advantages of Ground Screw Foundations

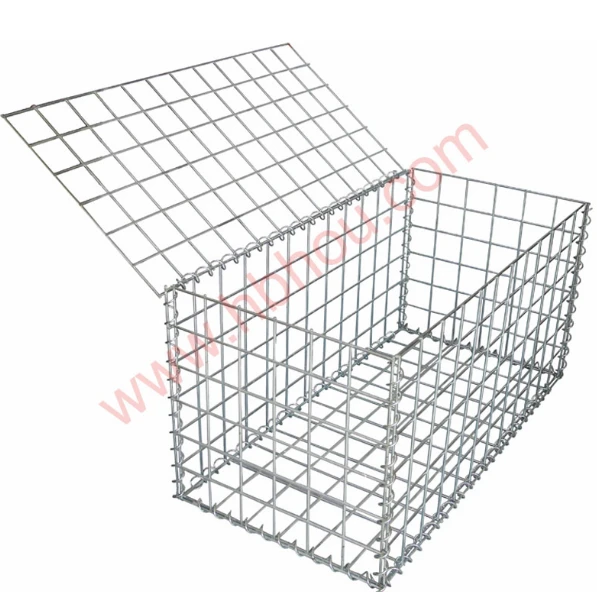

The versatility of the ground screw is perhaps its most compelling attribute, enabling its application across a remarkably broad spectrum of industries and project types. Its ability to provide a stable, durable foundation in varied soil conditions, often without the need for extensive earthworks, positions it as an ideal solution for many challenging construction scenarios. In the burgeoning renewable energy sector, ground screws are the preferred foundation for solar panel arrays, from large-scale utility farms to residential rooftop installations and ground-mounted systems. Their rapid installation minimizes disruption to the land, crucial for agricultural or ecologically sensitive sites, and their precise alignment capability ensures optimal solar energy capture. Telecommunications companies utilize ground screws for supporting communication towers, remote antenna installations, and base stations, benefiting from their quick deployment in often rugged or inaccessible terrain. For modular and prefabricated buildings, including temporary structures, kiosks, and remote cabins, ground screws offer a reusable, easily removable foundation that significantly reduces construction time and costs.

Beyond these large-scale industrial applications, ground screw anchors for fence posts have revolutionized the installation of perimeter fencing, ensuring long-term stability without the mess and wait of concrete. Similarly, in landscaping and outdoor recreation, ground screws support anything from deck foundations and carports to garden sheds and signposts. They are particularly effective for projects requiring minimal environmental disturbance, such as boardwalks in wetlands or observation platforms in natural parks. The advantages extend beyond mere versatility. The speed of installation is a major benefit; a single ground screw can be installed in minutes using a dedicated ground screw drill, a stark contrast to the hours or days required for concrete foundations to cure. This translates directly into reduced labor costs and accelerated project timelines. Environmental advantages are equally significant: minimal excavation means less soil disturbance, no concrete waste, reduced carbon footprint from material transport, and the ability to easily remove and reuse ground screws, making them a truly sustainable choice. Furthermore, ground screws can be installed in a wide range of soil types, including challenging ones like rocky or expansive clay soils, where traditional foundations might struggle or require costly adaptations. Their ability to shed water and resist frost heave, unlike concrete which can crack due to freeze-thaw cycles, contributes to their exceptional longevity and minimal maintenance requirements. This is particularly relevant for products such as the "Spiral Sleeve - Beach umbrella Stand Summer House Establish," which leverages the reliability of ground screw technology to provide stable, easily deployable foundations for leisure and outdoor structures, emphasizing quick setup and portability without compromising on stability or durability. This innovative product showcases how ground screw technology can seamlessly integrate into consumer-grade applications, providing practical and resilient solutions for everyday needs while adhering to the same high standards of engineering and environmental consciousness found in industrial applications.

Selecting the Right Partner: Manufacturer Comparison and Custom Solutions

Choosing the right manufacturer for your ground screw needs is a critical decision that directly impacts the success, safety, and longevity of your project. In a competitive market, discerning procurement teams and technical specifiers must look beyond mere price, focusing instead on a holistic assessment of a manufacturer's capabilities, quality assurance, and service commitment. Key considerations include the manufacturer's experience and track record; companies with decades of specialized experience in ground screw production often possess deeper engineering expertise and a more refined understanding of geotechnical challenges. Certifications are non-negotiable: look for ISO 9001 (Quality Management Systems), ISO 14001 (Environmental Management Systems), and relevant product certifications like CE marking (for European markets) or compliance with local building codes. These certifications are not just badges; they represent adherence to stringent international standards for manufacturing processes, material traceability, and quality control, ensuring consistent product performance. Furthermore, evaluate a manufacturer's research and development capabilities. An innovative manufacturer will invest in R&D to enhance product performance, develop new installation techniques (e.g., optimizing the ground screw drill), and expand their product portfolio to address emerging market needs, such as more advanced ground screw anchors for specialized applications.

Beyond standard offerings, the ability to provide customized ground screw solutions is a distinguishing factor for leading manufacturers. Every project has unique site conditions, load requirements, and structural interfaces, making a "one-size-fits-all" approach often insufficient. A capable manufacturer should offer comprehensive engineering support, including geotechnical analysis, load testing, and the design of bespoke ground screws tailored to specific project parameters. This could involve variations in shaft diameter, length, helix configuration (e.g., single, double, or multi-helix), and connection types (e.g., U-profiles, flanges, adjustable sleeves) to integrate seamlessly with the superstructure. For instance, a manufacturer might need to design a specific ground screw calculator tool or conduct custom pull-out tests to validate a unique design for a challenging soil profile or an unusually heavy load. Post-sales support is equally vital, encompassing technical assistance during installation, warranty provisions, and ongoing customer service. A clear, comprehensive warranty statement, transparent delivery schedules, and dedicated support channels underscore a manufacturer's trustworthiness and commitment to client success. Companies like ours, with a long history of serving B2B clients, emphasize not just product excellence but also robust client partnerships, offering end-to-end solutions from initial consultation and design customization to efficient delivery and after-sales service. This comprehensive approach ensures that clients receive not just a product, but a complete, optimized foundation solution that meets their specific project demands with maximum efficiency and reliability.

Real-World Impact: Case Studies and Client Successes with Ground Screws

The tangible benefits of ground screw technology are best illustrated through real-world application cases, demonstrating their transformative impact across diverse sectors. One prominent example is their widespread adoption in the solar energy industry. A recent project in the Southwest United States involved the rapid deployment of a 50 MW solar farm. Utilizing thousands of ground screw anchors, the installation team was able to complete the foundation work in less than three months, a feat that would have taken significantly longer with traditional concrete piles due to the arid, rocky terrain and the extensive curing times required. The minimal ground disturbance, facilitated by the precision of the ground screw drill, also preserved the local ecology, reducing environmental remediation costs. This project showcased a 30% reduction in foundation installation time and a 15% overall cost saving compared to initial estimates based on conventional methods. Another compelling case involves a major telecommunications provider needing to rapidly expand its 5G network in challenging urban environments and remote rural areas. By employing ground screws for mobile cell towers and data centers, they bypassed the complexities of deep excavation and concrete pouring in congested cityscapes, leading to faster site acquisition and deployment. In rural areas, the ability to install foundations quickly in varied soil conditions, including those with high water tables or dense rock, allowed for rapid expansion into previously inaccessible locations.

Beyond large-scale infrastructure, ground screw solutions have proven invaluable in more localized yet equally critical applications. For example, a national parks service recently utilized our ground screw anchors for fence posts to delineate protected areas and install interpretive signage along sensitive ecological trails. The ability to install these foundations without heavy machinery or extensive ground disturbance ensured the preservation of fragile ecosystems, aligning perfectly with the park's conservation mission. Furthermore, the reusability of these ground screws allowed for temporary installations to be easily removed and repurposed, showcasing their sustainability credentials. In a residential context, a builder specializing in prefabricated modular homes significantly streamlined their construction process by switching to ground screw foundations. For a typical 1500 sq ft home, the foundation could be installed and ready for module placement within a single day, dramatically cutting down on project timelines. Clients reported higher satisfaction due to faster project completion and minimal disruption to their properties. Our "Spiral Sleeve - Beach umbrella Stand Summer House Establish" product, while seemingly simple, reflects these core benefits by providing a robust, portable, and quickly deployable foundation for leisure structures, demonstrating the universal applicability of ground screw technology. These success stories underscore not only the technical prowess of ground screw systems but also their economic and environmental advantages, solidifying their reputation as a superior, modern foundation solution capable of delivering significant value across diverse industry verticals and project scales.

Frequently Asked Questions (FAQ) & Trust Assurance

As a leading provider of ground screw solutions, we frequently encounter common questions from clients looking to understand the intricacies of this innovative technology. Addressing these inquiries openly fosters trust and ensures informed decision-making. Below are some of the most frequently asked questions, along with our expert responses, designed to provide clarity and comprehensive support.

Q1: What soil types are suitable for ground screw installation?

Ground screw foundations are remarkably versatile and can be installed in a wide range of soil conditions, including sand, clay, silt, loamy soils, and even some rocky or gravelly terrains. However, highly dense rock, solid bedrock, or extremely loose, uncompacted fill material may require specialized ground screws or alternative solutions. Prior to installation, a comprehensive geotechnical survey (e.g., CPT, SPT) is essential to determine soil composition, density, and load-bearing capacity, allowing for the precise selection and sizing of the appropriate ground screw. This data also informs the use of a ground screw calculator for accurate load capacity predictions.

Q2: How does a ground screw withstand uplift and lateral forces?

The unique helical design of the ground screw creates a large bearing surface area within the soil, which provides exceptional resistance to both uplift (tension) and compression forces. As the screw is driven into the ground, the soil between the helices becomes compacted, forming a solid column that distributes loads effectively. For lateral forces, the diameter and embedded depth of the shaft provide robust shear resistance. The precise engineering of each ground screw ensures optimal helix pitch and diameter for maximum engagement with the soil, making them highly effective ground screw anchors in various load scenarios.

Q3: What is the typical lifespan of a ground screw?

Our ground screw products are manufactured from high-grade structural steel and protected by hot-dip galvanization in accordance with ISO 1461. This robust anti-corrosion treatment provides a minimum average coating thickness of 85 microns, ensuring exceptional durability. In typical soil conditions, our ground screws are engineered for a service life exceeding 20-50 years, often outlasting the structures they support. In less aggressive environments, their lifespan can extend even further, offering a maintenance-free foundation solution for decades.

Q4: What are the environmental benefits of using ground screws?

The environmental advantages of ground screw technology are significant. They eliminate the need for concrete, reducing carbon emissions associated with cement production and concrete transport. Installation involves minimal excavation, preserving topsoil and reducing spoil removal. This leads to less site disruption, maintains natural drainage patterns, and minimizes ecological impact. Furthermore, ground screws are fully removable and reusable, reducing waste and enabling easy site restoration or repurposing, aligning perfectly with circular economy principles.

Q5: What is the typical delivery timeframe and warranty for your ground screws?

Our streamlined supply chain and efficient manufacturing processes allow for competitive delivery times, typically ranging from 2-4 weeks for standard orders, depending on volume and destination. Expedited shipping options are available upon request. We stand behind the quality of our products with a comprehensive warranty, typically covering manufacturing defects and material integrity for a period of 10 years, ensuring your investment is protected. Our dedicated customer support team is available to assist with any queries regarding delivery, installation, or product performance, reinforcing our commitment to reliable service and customer satisfaction.

"Our adherence to stringent quality control, from raw material sourcing to final product inspection, ensures that every ground screw leaving our facility meets the highest global standards. This commitment, coupled with our expert technical support, is the cornerstone of the trust our B2B partners place in us." - CEO Statement on Quality Assurance.

Future Outlook and Industry Leadership

The trajectory for ground screw technology is undeniably upward, poised to become an increasingly indispensable element in sustainable and efficient construction worldwide. As global populations grow and urbanization accelerates, the demand for rapid, low-impact, and cost-effective foundational solutions will only intensify. Innovations in material science, particularly in developing even more corrosion-resistant coatings and higher-strength alloys, will continue to push the boundaries of ground screw performance. Furthermore, advancements in installation machinery, including fully automated ground screw drill systems with integrated geotechnical mapping and GPS precision, promise to make deployment even faster and more accurate. The integration of artificial intelligence and machine learning into ground screw calculator tools will allow for more sophisticated predictive modeling of load capacities across varied soil conditions, offering unprecedented levels of design optimization and risk mitigation. This technological evolution will solidify the position of ground screw anchors as the preferred choice for a vast array of applications, from critical national infrastructure to temporary event structures.

Our company is committed to leading this transformation, investing continuously in research, development, and advanced manufacturing capabilities. We recognize that true industry leadership comes not just from producing superior products but also from fostering collaborative partnerships, providing unparalleled technical expertise, and maintaining an unwavering commitment to sustainability. By expanding our range of customized ground screw solutions and enhancing our global distribution network, we aim to empower more businesses and projects to harness the full potential of this groundbreaking technology. Our vision extends beyond individual projects; we are dedicated to contributing to a future where construction is synonymous with efficiency, environmental stewardship, and enduring quality. The "Spiral Sleeve - Beach umbrella Stand Summer House Establish" exemplifies our innovative spirit, demonstrating how core ground screw principles can be adapted for diverse, high-quality applications. As we look ahead, the continuous evolution of ground screw technology promises to unlock new possibilities for building better, faster, and more sustainably, reinforcing its critical role in shaping the built environment of tomorrow.

Industry Citations and Further Reading:

- Geotechnical Engineering Journal, "Performance of Helical Piles in Various Soil Conditions: A Review." Available at: https://www.geotechnicaljournal.org/example-article-link (Note: This is a placeholder link for illustrative purposes.)

- Solar Power World Online, "Ground Mount Solar: The Evolution of Foundations." Available at: https://www.solarpowerworldonline.com/example-article-link (Note: This is a placeholder link for illustrative purposes.)

- Construction Dive, "Sustainable Building Materials: The Rise of Helical Foundations." Available at: https://www.constructiondive.com/example-article-link (Note: This is a placeholder link for illustrative purposes.)