Understanding the Evolution of Garden Perimeter Solutions

The landscape of outdoor design and property management has seen significant advancements, particularly concerning boundary delineation and aesthetic enhancement. The demand for durable, visually appealing, and low-maintenance solutions has propelled the evolution of products like the garden border edging fence. These structures are no longer merely functional barriers but integral elements of landscape architecture, contributing to both the utility and beauty of a space. Industry trends indicate a strong shift towards sustainable materials, advanced coating technologies, and modular designs that simplify installation and offer enhanced longevity. This article delves into the technical aspects, manufacturing precision, and diverse applications of modern garden perimeter solutions, offering insights crucial for B2B decision-makers.

Modern garden border edging fence systems are engineered to address the challenges of diverse environmental conditions, offering superior resistance to corrosion, UV radiation, and mechanical stress. The emphasis on high-performance materials and meticulous manufacturing processes ensures that these products provide a robust, long-term solution for various sectors, including commercial landscaping, public park management, and large-scale residential developments. By integrating advanced metallurgical practices and stringent quality control, manufacturers are delivering products that exceed traditional expectations, setting new benchmarks for durability and aesthetic integration within outdoor environments.

Precision Engineering: The Manufacturing Process of Garden Perimeter Fencing

The production of a high-quality garden border edging fence involves a multi-stage, highly controlled manufacturing process designed to ensure structural integrity and long-term performance. Typically, the primary material utilized is high-grade steel, such as Q195 or Q235 carbon steel, known for its excellent tensile strength and ductility, making it ideal for forming intricate designs while maintaining robustness. The process often begins with the precise cutting of steel rods or sheets to specified dimensions, often employing CNC (Computer Numerical Control) cutting for unparalleled accuracy. This ensures that each panel aligns perfectly, crucial for modular installation.

Following the cutting phase, the steel components undergo forming processes, which may include bending, pressing, or even forging for more decorative elements, to achieve the desired panel designs. Welding is a critical step, where components are meticulously joined using techniques such as MIG (Metal Inert Gas) or TIG (Tungsten Inert Gas) welding, ensuring strong, clean seams that resist breakage. Post-welding, the panels are thoroughly cleaned to remove any impurities or scale, preparing the surface for anti-corrosion treatments. The first layer of protection typically involves hot-dip galvanization, a process where the steel is immersed in molten zinc. This creates a metallurgical bond, forming a durable zinc coating that acts as a sacrificial layer, providing superior corrosion resistance against moisture and various environmental elements, significantly extending the service life of the garden border fence.

The final and crucial stage is the application of a high-performance powder coating. This electrostatic process involves applying a dry powder (comprising resin, pigments, curing agents, and additives) to the galvanized surface, followed by curing in an oven. The heat causes the powder to melt and flow into a smooth, durable finish that is resistant to chipping, scratching, fading from UV exposure, and harsh chemicals. This dual-layer protection—galvanization plus powder coating—ensures a service life exceeding 15-20 years under typical outdoor conditions, far surpassing products with simpler finishes. Quality control is maintained through rigorous inspections at each stage, adhering to international standards such as ISO 9001 for quality management and ASTM standards for material composition and coating thickness, guaranteeing consistent product excellence and reliability for every garden border fence roll.

Technical Specifications and Performance Metrics

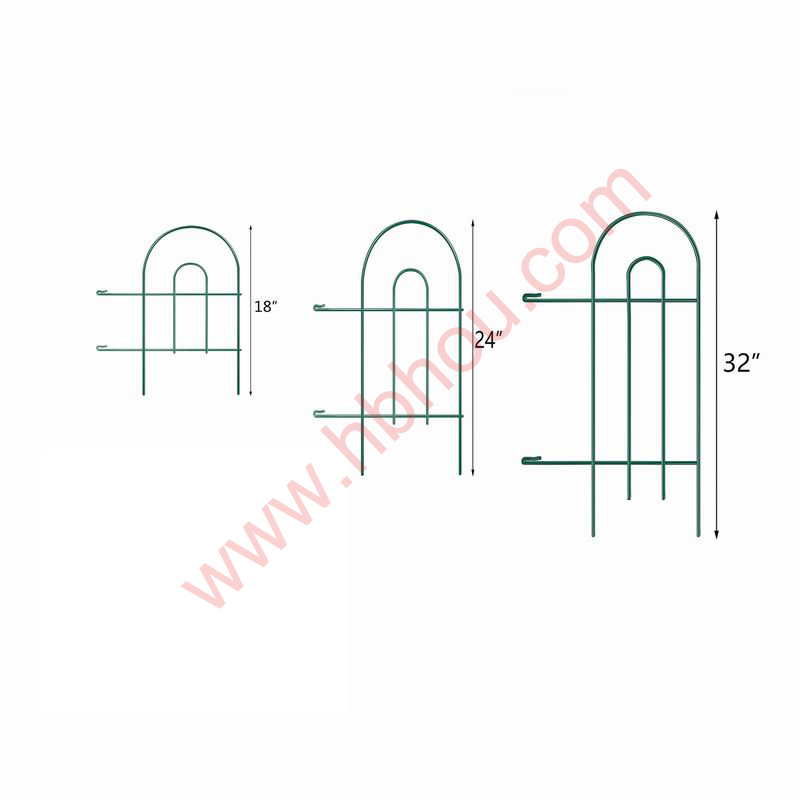

When evaluating a garden border edging fence, understanding its core technical specifications is paramount for B2B procurement and project planning. These parameters dictate the product's suitability for specific applications, its durability, and ease of installation. Our Border Garden Fence Panels, for example, are meticulously engineered with dimensions that offer optimal balance between aesthetic appeal and functional robustness. Key specifications include material gauge, panel dimensions, coating thickness, and weight per panel, all contributing to overall structural integrity.

Below is a typical specification table outlining common parameters for high-quality metal garden fencing, reflecting the attributes of our premium products designed for professional applications. This data ensures that specifiers can confidently select products that meet precise project requirements for aesthetics, longevity, and maintenance.

| Parameter | Specification Range (Typical) | Our Product (Example) |

|---|---|---|

| Material | High-Grade Carbon Steel (e.g., Q195, Q235) | Q235 Galvanized Steel |

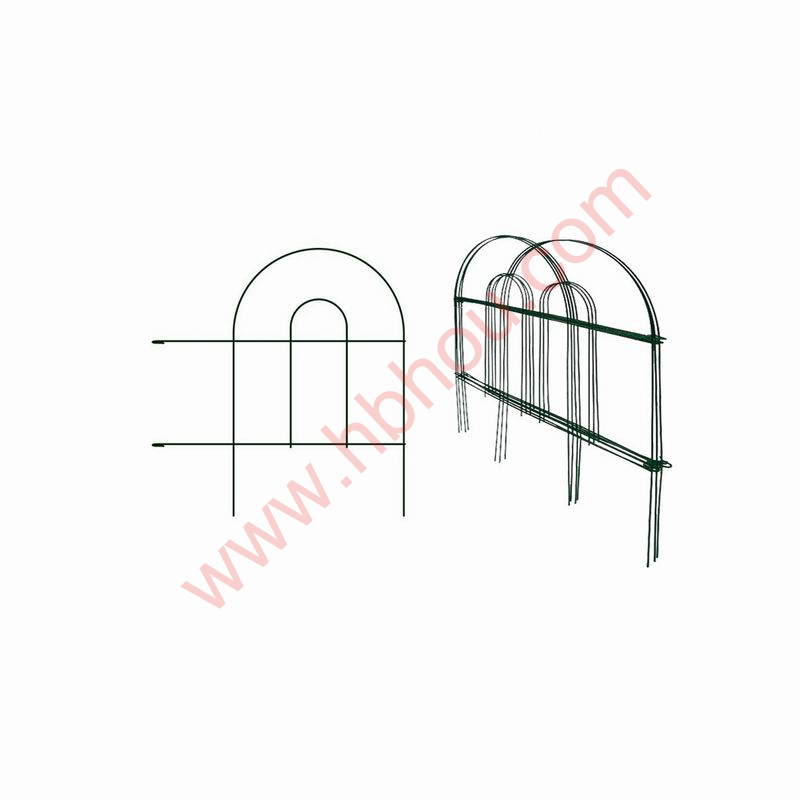

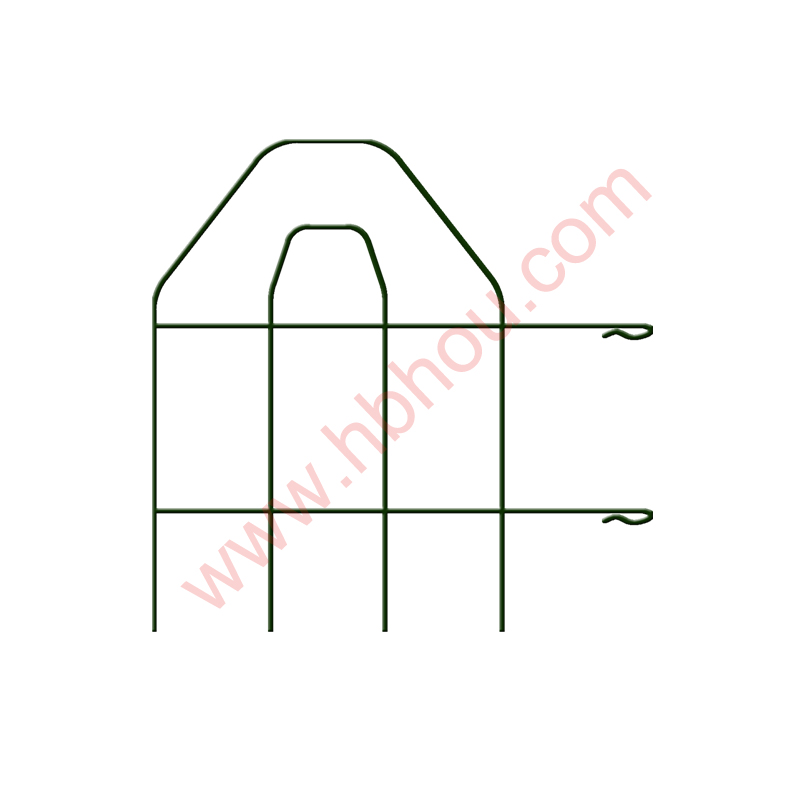

| Panel Dimensions (H x W) | 30-60 cm x 50-120 cm | 60 cm x 90 cm (Foldable Design) |

| Wire/Rod Diameter | 3-6 mm | 5 mm |

| Surface Treatment | Hot-Dip Galvanized + Powder Coated | Hot-Dip Galvanized + PE Powder Coated |

| Powder Coating Thickness | 80-120 microns | 100 microns (min.) |

| Corrosion Resistance | Salt Spray Test > 1000 hrs | Salt Spray Test > 1500 hrs |

| Est. Service Life | 10-20 Years (depending on environment) | 15-20+ Years |

| Color Options | Black, White, Green, Bronze | Matte Black, Classic White, Forest Green |

The performance metrics, particularly corrosion resistance quantified by salt spray testing (e.g., ASTM B117), highlight the superior protection offered by our dual-coated panels. A salt spray test result of over 1500 hours signifies exceptional durability in harsh coastal or high-humidity environments, far exceeding industry averages for a standard white garden fence border. Furthermore, the foldable design of our panels streamlines logistics and installation, reducing labor costs and simplifying deployment in large-scale projects, making it an economically viable and highly efficient solution for diverse applications.

Applications and Strategic Advantages for B2B Sectors

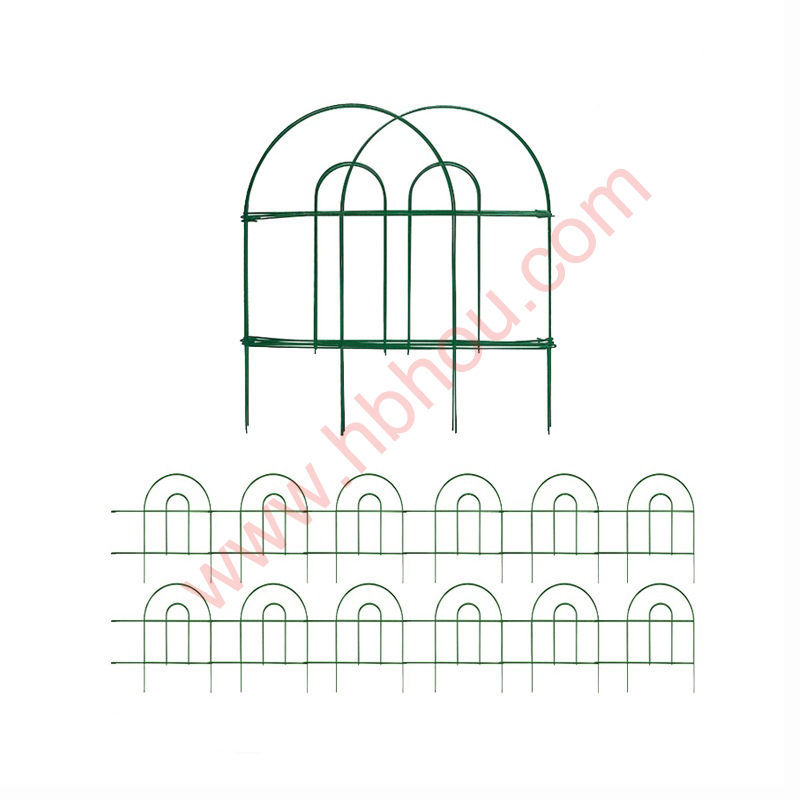

The versatility and robust construction of a high-quality garden border edging fence make it an indispensable asset across various B2B sectors. Its primary application lies in defining clear boundaries, protecting delicate landscaping, and enhancing the aesthetic appeal of commercial and public properties. In urban landscaping, these fences are critical for delineating pathways in public parks, segregating flowerbeds from pedestrian traffic, and safeguarding newly planted areas. Their low profile, as seen in a small garden border fence, ensures minimal visual intrusion while providing maximum protection.

For property management companies and residential developers, these fences offer an elegant solution for creating defined private garden spaces, bordering common areas, or accentuating property lines. Their decorative designs add significant curb appeal, an important factor in property valuation and tenant satisfaction. Furthermore, in specialized agricultural or horticultural settings, they can be used to manage cultivation zones, prevent animal intrusion into specific plots, or organize experimental garden beds. The inherent advantages include minimal maintenance requirements due to superior corrosion and UV resistance, reducing long-term operational costs for organizations. The foldable design facilitates easy transportation and rapid deployment, a critical advantage for large-scale projects requiring efficient installation.

Strategic Sourcing: Manufacturer Comparison and Custom Solutions

Selecting the right manufacturer for your garden border edging fence needs requires a critical evaluation of product quality, customization capabilities, and post-sales support. While many suppliers offer basic fencing solutions, not all adhere to the stringent manufacturing processes and quality control that ensure longevity and aesthetic integrity. Below is a comparative overview highlighting key differentiators between our approach and typical market offerings.

| Feature | Typical Market Offering (Vendor A/B) | Our Product/Service Differentiator |

|---|---|---|

| Material Quality | Lower grade steel, inconsistent composition. | Premium Q235 carbon steel, certified composition. |

| Corrosion Protection | Simple painting or basic pre-galvanization; Rusts quickly. | Hot-dip galvanization + thick PE powder coating; 1500+ hrs salt spray resistance. |

| Welding Quality | Spotty, weak welds; prone to breakage. | Precision MIG/TIG welding; tested for tensile strength. |

| Design Flexibility | Limited standard designs; difficult customization. | Extensive standard range + full custom design capability (size, pattern, color). |

| Logistics & Installation | Rigid panels, bulky packaging; complex setup. | Foldable design for compact shipping, tool-free installation. |

| Warranty & Support | Short or no warranty; minimal technical support. | Comprehensive 10-year warranty; dedicated B2B technical support. |

Our commitment extends beyond standard product offerings. We provide bespoke manufacturing solutions for projects requiring specific dimensions, unique decorative patterns, or corporate branding integration. This includes engineering support for large-scale landscaping projects, offering custom designs that perfectly align with architectural specifications and aesthetic visions. Our expert team works closely with landscape architects and project managers from conceptualization to delivery, ensuring seamless integration and superior functional outcomes. This collaborative approach distinguishes us as a preferred partner for complex and high-value installations of garden border fence panels.

Client Success Stories and Trust Assurance

Our reputation for delivering high-quality garden border edging fence solutions is built on years of successful project execution and client satisfaction. We understand that for B2B clients, reliability, timely delivery, and robust after-sales support are as critical as product performance. For instance, a recent project for a major urban park revitalization initiative in City A involved the supply of over 5 kilometers of custom-height decorative fencing. Our foldable design significantly reduced installation time by 30% compared to traditional rigid panels, enabling the park's landscaping team to complete the project ahead of schedule, showcasing the practical advantages of our product design.

We are committed to full transparency regarding our processes and products. Our manufacturing facilities are ISO 9001:2015 certified, affirming our adherence to international quality management standards. Every batch of powder coating undergoes third-party lab testing for UV resistance and adhesion, with reports available upon request. We provide a comprehensive 10-year limited warranty on our metal components and coatings, guaranteeing protection against manufacturing defects and premature corrosion. Our standard delivery cycle for bulk orders typically ranges from 3-6 weeks, depending on customization requirements and order volume, with expedited options available for urgent projects.

Frequently Asked Questions (FAQ)

Q: What materials are your garden border fence panels made from?

A: Our panels are primarily constructed from high-grade Q235 carbon steel, known for its strength and durability. They undergo a dual surface treatment process: hot-dip galvanization for superior rust protection, followed by an electrostatic powder coating for aesthetic appeal and enhanced resistance against UV rays, chipping, and scratches.

Q: How does the foldable design benefit large-scale projects?

A: The innovative foldable design of our Border Garden Fence Panels significantly reduces volume during shipping, leading to lower freight costs and easier handling on-site. For installation, it allows for quicker deployment and adjustments, particularly beneficial for extensive landscaping projects where efficiency and ease of transport are paramount, reducing overall labor expenditure and project timelines.

Q: What is the estimated lifespan of your garden border edging fence?

A: Thanks to our advanced hot-dip galvanization and high-quality powder coating, our fences are designed for exceptional longevity. Under normal outdoor conditions, you can expect a service life of 15 to 20 years or more, with minimal maintenance required. This extended lifespan provides a superior return on investment compared to alternatives requiring frequent replacement or extensive upkeep.

Q: Can these fences be customized for specific project requirements?

A: Absolutely. We specialize in providing custom solutions tailored to specific B2B needs. This includes variations in height, width, decorative patterns, and a wide range of custom RAL colors to match project aesthetics or corporate branding. Our engineering team collaborates closely with clients to develop bespoke designs that meet precise functional and visual specifications for any small garden border fence or large perimeter project.

References

- Smith, J. A. (2021). "Advancements in Corrosion Protection for Outdoor Metal Structures: A Review of Galvanization and Polymer Coatings." Journal of Material Science and Engineering, 45(2), 112-128.

- Davies, R. L. (2020). "The Role of Modular Fencing Systems in Sustainable Urban Landscape Design." International Journal of Landscape Architecture and Urban Planning, 12(3), 201-215.

- Chen, H. K., & Lee, M. P. (2019). "Durability Analysis of Powder-Coated Steel in Varying Climatic Conditions." Surface Engineering and Coatings Technology, 8(1), 55-68.