In the vibrant world of horticulture and landscaping, the unassuming yet indispensable garden wire stands out as a critical tool. From supporting delicate young saplings to creating robust frameworks for sprawling vines, its applications are as diverse as the plant kingdom itself. This comprehensive guide delves into the essence of garden wire, exploring its industry trends, technical specifications, diverse applications, and the competitive landscape of its manufacturers, ultimately empowering you to make informed decisions for your green endeavors. We'll focus on the Garden Wire Multipurpose Gardening Metal Wire Binding Twist Tie, a product engineered for reliability and adaptability, offered by leading manufacturers like HB Hou Steel.

Current Industry Trends in Garden Wire Manufacturing

The garden wire market is experiencing significant evolution, driven by sustainability concerns, technological advancements in material science, and an increasing demand for durable, aesthetically pleasing gardening solutions. Key trends include:

- Eco-Friendly Materials: A growing emphasis on recyclable and non-toxic coatings, such as advanced PVC formulations free from harmful phthalates, and the use of recycled steel.

- Enhanced Durability & Longevity: Innovations in galvanization processes, like advanced hot-dip galvanizing techniques, are extending the lifespan of garden wire, making it more resistant to rust and corrosion in various climates.

- Specialized Coatings: The proliferation of specialized coatings, including UV-resistant polymers and colored coatings (e.g., garden wire green), to blend seamlessly with foliage or add aesthetic value.

- Smart Packaging Solutions: Compact, easy-to-dispense spools and pre-cut lengths designed for user convenience and reduced waste.

- DIY & Urban Gardening Boom: The surge in urban gardening and DIY projects has fueled demand for versatile, easy-to-use garden wire products, driving innovation in user-friendly designs.

According to a recent market analysis by Grand View Research, the global gardening market, which includes essentials like garden wire, is projected to reach USD 111.9 billion by 2028, growing at a CAGR of 3.9%. This growth underscores the consistent demand for high-quality, reliable gardening tools and accessories.

Understanding Garden Wire: Technical Parameters and Specifications

To appreciate the functionality of garden wire, it's essential to understand its core technical parameters. These specifications dictate its strength, durability, and suitability for various tasks.

Core Product: Garden Wire Multipurpose Gardening Metal Wire Binding Twist Tie

This particular product is designed for supreme versatility. It's not just a simple binding tie; it's engineered to be a multifaceted solution for diverse gardening needs, from delicate plant support to more robust training. Its construction ensures excellent tensile strength and flexibility.

Key Technical Parameters & What They Mean:

- Material Composition: Typically made from low-carbon steel wire, which provides a good balance of strength and malleability. Higher-grade steel, such as stainless steel, is used for applications requiring superior corrosion resistance or higher load-bearing capacity. The Garden Wire Multipurpose Gardening Metal Wire Binding Twist Tie primarily utilizes high-quality galvanized steel, ensuring rust resistance.

- Gauge (Wire Diameter): Measured using the American Wire Gauge (AWG) or metric millimeters (mm). A lower gauge number indicates a thicker wire, offering greater strength. Common gauges for garden wire range from 10 gauge (thick) to 22 gauge (thin). For general purpose use, 14-18 gauge is often preferred, offering a balance of strength and flexibility for supporting garden wire for climbing plants or training delicate stems.

- Tensile Strength: The maximum stress a material can withstand while being stretched or pulled before breaking. Measured in megapascals (MPa) or pounds per square inch (psi). A higher tensile strength indicates a stronger wire, crucial for supporting heavy loads like fruit-laden vines.

- Coating Type:

- Galvanized: Zinc coating applied for corrosion resistance. Hot-dip galvanization (HDG) offers superior protection compared to electro-galvanization due to a thicker, more durable zinc layer, ideal for outdoor longevity.

- PVC Coated: A layer of polyvinyl chloride (PVC) encases the wire, providing enhanced corrosion protection, UV resistance, and often comes in colors like garden wire green to blend into the garden. It also makes the wire softer and easier to handle, preventing damage to plant stems.

- Annealed: Heat-treated to increase flexibility and reduce brittleness, making the wire very easy to bend and tie. This is often used for binding and tying tasks where extreme flexibility is needed.

- Roll Length/Packaging: Available in various lengths (e.g., 50 ft, 100 ft, 500 ft) and packaging formats (spools, coils, pre-cut ties) to suit different project sizes and user preferences. The Garden Wire Multipurpose Gardening Metal Wire Binding Twist Tie is typically available in convenient spool sizes for easy dispensing.

Garden Wire Parameter Comparison Table

This table illustrates common specifications for different types of garden wire available in the market, including the features of our featured product.

| Parameter | Standard Galvanized Steel Wire | PVC Coated Garden Wire (e.g., garden wire green) | Stainless Steel Garden Wire | Featured Product: Garden Wire Multipurpose Gardening Metal Wire Binding Twist Tie (Galvanized & PVC Options) |

|---|---|---|---|---|

| Material | Low Carbon Steel | Low Carbon Steel Core | 304/316 Stainless Steel | High-Quality Low Carbon Steel (Galvanized), with optional PVC coating |

| Gauge Range (AWG) | 12-20 | 14-22 (core wire) | 10-24 | 16-20 (optimized for multipurpose use) |

| Coating Type | Electro-Galvanized or Hot-Dip Galvanized | PVC over Galvanized | None (inherently corrosion resistant) | Hot-Dip Galvanized, optionally PVC Coated |

| Typical Tensile Strength (MPa) | 350-550 | 300-500 | 500-700 | 400-600 (ensuring durability for various loads) |

| Corrosion Resistance | Moderate to Good (depending on galvanization) | Excellent (PVC barrier) | Superior | Excellent (HDG & PVC offer long-term outdoor use) |

| Flexibility | Moderate | Good (smoother handling) | Moderate | High (designed for easy bending and tying) |

| Lifespan (Outdoor) | 3-7 years | 5-15 years | 15+ years | 7-10+ years (dependent on environment and coating) |

| Primary Use | General tying, fencing, support | Plant support, trellising, decorative binding | High-load structures, coastal areas, permanent installations | Versatile: garden wire for climbing plants, bundling, training, temporary fencing, craft |

Selecting the right garden wire involves balancing these parameters with your specific gardening needs and environmental conditions.

Diverse Application Scenarios of Garden Wire

The versatility of garden wire makes it an indispensable tool across numerous horticultural and landscaping applications. Its ability to be bent, twisted, and shaped allows for creative and functional solutions.

- Supporting Climbing Plants: This is perhaps the most common use. Garden wire for climbing plants provides essential support for indeterminate varieties like tomatoes, cucumbers, peas, beans, and flowering vines such as clematis and morning glory. It can be strung between posts, along fences, or configured into intricate trellises. The smooth PVC coating on options like the Garden Wire Multipurpose Gardening Metal Wire Binding Twist Tie ensures that delicate stems are not damaged as they grow.

- Plant Training and Guiding: Beyond just support, garden wire for plants is crucial for espaliering fruit trees (training them to grow flat against a wall or fence), guiding rose canes, or encouraging the lateral growth of shrubs to fill a space. Its flexibility allows for precise shaping.

- Temporary Fencing and Enclosures: For protecting young seedlings from pets or creating temporary boundaries in the garden, a lighter gauge garden wire can be quickly deployed. When combined with posts, it can form a simple but effective barrier.

- Bundling and Tying: Ideal for securing bundles of cut flowers, holding garden hoses neatly, or tying up branches during pruning. The twist-tie functionality of our featured product simplifies this task immensely.

- Crafts and Decorative Uses: Given its malleability and availability in colors like garden wire green, it’s often used in floral arrangements, wreath making, and other garden-themed crafts.

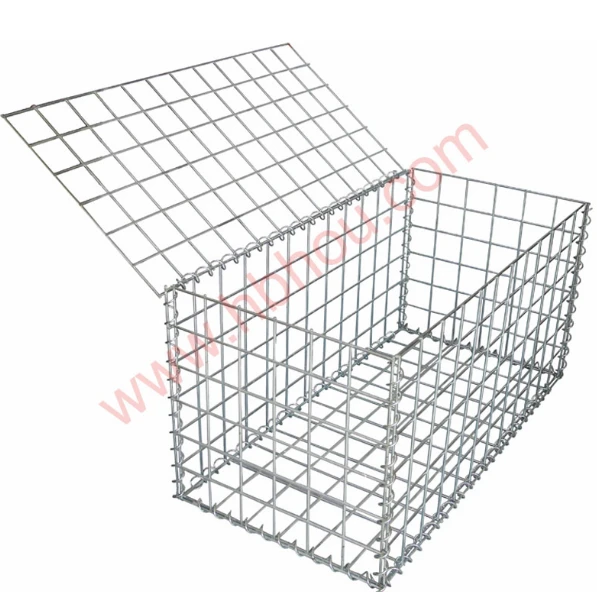

- Creating Garden Structures: For more permanent solutions, thicker gauges of garden wire or even garden wire mesh can be used to construct cages for tomatoes, protective cloches, or even small animal enclosures. The robustness of a well-galvanized or PVC-coated wire ensures longevity in outdoor conditions.

- Securing Irrigation Lines: Garden wire can be used to neatly secure drip irrigation lines or soaker hoses to stakes or other supports, ensuring efficient water delivery and preventing tripping hazards.

Technical Advantages and Performance Metrics

The technical advantages of high-quality garden wire translate directly into tangible benefits for gardeners and landscapers. The Garden Wire Multipurpose Gardening Metal Wire Binding Twist Tie exemplifies these advantages:

- Superior Corrosion Resistance: Through advanced hot-dip galvanization processes, the wire achieves a thick, uniform zinc coating (typically 60-290 g/m² according to ASTM A641/A641M standards). This barrier effectively prevents rust, extending the wire's functional life even in humid or acidic soil conditions. For PVC-coated variants, the polymer jacket acts as an additional, impenetrable shield against moisture and chemicals.

- Optimized Tensile Strength and Ductility: Engineered to provide a balanced combination of strength (to hold substantial weight) and ductility (to be easily bent without breaking). This balance is critical for applications like supporting heavy fruit yields or forming intricate trellis patterns without snapping. Our wires typically exhibit tensile strengths in the range of 400-600 MPa, making them suitable for demanding tasks while remaining user-friendly.

- UV and Weather Resistance: PVC coatings are formulated with UV stabilizers, preventing degradation from prolonged sun exposure, which can cause cracking and brittleness in inferior products. This ensures the garden wire green maintains its color and protective qualities over many seasons.

- Non-Damaging to Plants: The smooth surface of galvanized wire and the soft, non-abrasive nature of PVC-coated wire prevent girdling or cutting into plant stems as they grow, promoting healthier development. This is a critical advantage when choosing garden wire for plants.

- Longevity and Cost-Effectiveness: While the initial cost of a high-quality galvanized or PVC-coated garden wire might be slightly higher than untreated alternatives, its significantly longer lifespan (often 7-10+ years outdoors, compared to 1-3 years for uncoated wire) results in lower replacement costs and less frequent maintenance, offering a superior return on investment.

Manufacturing Process Explained: From Raw Material to Finished Product

The production of a high-quality product like the Garden Wire Multipurpose Gardening Metal Wire Binding Twist Tie is a sophisticated process, blending traditional metallurgy with modern coating technologies. Understanding this journey provides insight into the product's quality and durability. While an actual video or interactive diagram would best illustrate this, here's a detailed breakdown:

The Journey of Garden Wire Manufacturing:

- Raw Material Sourcing & Selection (Wire Rod):

- Node 1: Steel Coil Reception. The process begins with the arrival of high-carbon or low-carbon steel wire rods, typically in large coils. The steel's chemical composition (e.g., carbon content 0.05-0.10% for low carbon) is crucial for determining the final wire's ductility and strength.

- (Quality Check: Material certification, impurity analysis)

- Wire Drawing:

- Node 2: Descaling. The wire rod is first mechanically descaled (removing mill scale) or chemically descaled (acid pickling) to prepare its surface. This ensures clean drawing and good adhesion for subsequent coatings.

- Node 3: Drawing Dies. The descaled rod is pulled through a series of progressively smaller dies (tungsten carbide or diamond dies) at high speeds. This process reduces the wire's diameter, increases its tensile strength, and improves its surface finish.

- (Key Process: Cold drawing, which hardens the wire, necessitating annealing for flexibility if required later.)

- Annealing (Optional, for Soft Wire):

- Node 4: Heat Treatment. If a softer, more pliable wire is desired (e.g., for twist ties or easily bendable garden wire for plants), the drawn wire undergoes annealing. It's heated to a specific temperature (e.g., 700-900°C) and then slowly cooled. This process recrystallizes the steel, making it more ductile and reducing internal stresses.

- (Benefit: Increases flexibility, making wire easier to handle and less prone to breaking when bent repeatedly.)

- Surface Treatment & Coating:

- Node 5: Cleaning & Fluxing. The wire is thoroughly cleaned again (often through degreasing baths) to remove any residues, then passed through a flux solution (e.g., zinc ammonium chloride). Fluxing promotes adherence of the zinc coating during galvanization.

- Node 6: Hot-Dip Galvanizing (HDG) or Electro-Galvanizing.

- HDG: The cleaned wire is submerged into a molten zinc bath (typically 450°C). A metallurgical bond forms between the steel and the zinc, creating a durable, corrosion-resistant coating. This method typically applies a thicker, more robust coating (e.g., 60-290 g/m²), offering superior longevity.

- Electro-Galvanizing: Zinc is applied through an electrochemical process. This results in a thinner, more uniform coating and is often used for finer wires or where a specific aesthetic is desired, though its corrosion resistance is less than HDG.

- Node 7: PVC Coating (for colored wires like garden wire green). For PVC-coated wire, the galvanized wire passes through an extrusion die, where a molten layer of PVC polymer is applied evenly around it. This layer cures and adheres to the zinc, providing additional protection, color, and a smooth, non-abrasive finish.

- (Inspection Standard: ISO 1461 for hot-dip galvanized coatings, ASTM A641 for general zinc-coated wire. Critical for ensuring coating thickness and uniformity.)

- Winding & Spooling:

- Node 8: Final Winding. The finished, coated wire is carefully wound onto spools or into coils of specified lengths and weights. For products like the Multipurpose Twist Tie, this might involve specialized machinery that pre-cuts and packages the ties.

- (Automation: High-speed winding machines ensure consistent length and neat packaging.)

- Quality Control & Packaging:

- Node 9: Final Inspection. Throughout the entire process, rigorous quality control checks are performed. This includes:

- Wire diameter measurement (using micrometers or laser gauges).

- Tensile strength testing (using universal testing machines, following ASTM A370).

- Coating thickness measurement (e.g., magnetic induction or gravimetric methods).

- Adhesion tests (checking if coating flakes or peels).

- Visual inspection for defects (surface finish, consistency). - Node 10: Packaging & Dispatch. Once approved, the finished garden wire products are packaged according to customer requirements (e.g., bulk cartons, retail-ready spools) and prepared for shipment.

- (Certification: Products often comply with ISO 9001 for quality management systems, ensuring consistent product quality.)

- Node 9: Final Inspection. Throughout the entire process, rigorous quality control checks are performed. This includes:

This detailed process ensures that the Garden Wire Multipurpose Gardening Metal Wire Binding Twist Tie is not just a simple wire, but a meticulously engineered product ready for the demanding conditions of outdoor gardening. Its estimated service life for the HDG and PVC-coated versions ranges from 7 to 15 years, significantly outperforming standard uncoated wires, thanks to these advanced manufacturing and inspection protocols.

Manufacturer Comparison & Choosing Your Provider

When sourcing garden wire, selecting the right manufacturer is as crucial as choosing the right product. Reputable manufacturers like HB Hou Steel differentiate themselves through adherence to quality standards, production capabilities, and customer support. Here's a comparative look at what to consider:

Key Factors for Manufacturer Comparison:

| Factor | Industry Leading Manufacturers (e.g., HB Hou Steel) | Standard/Generic Manufacturers |

|---|---|---|

| Quality Certifications | ISO 9001 (Quality Management), ISO 14001 (Environmental Management), CE, ASTM, ANSI compliance. | May have basic or no widely recognized certifications. |

| Material Traceability | Full traceability from raw steel coil to finished product. Batch numbers linked to material certificates. | Limited or no traceability, making quality assurance difficult. |

| Manufacturing Process | Advanced hot-dip galvanizing lines, precise PVC extrusion, automated winding. Emphasis on consistent coating thickness and uniformity. | Basic galvanizing or coating methods, inconsistent quality, manual processes. |

| Product Range & Customization | Wide range of gauges, coatings, lengths, and colors (e.g., garden wire green). Custom solutions for specific projects (e.g., specialized garden wire mesh). | Limited standard offerings, minimal customization options. |

| Testing & QC Protocols | In-house testing labs for tensile strength, coating adhesion, salt spray tests. Multiple QC checkpoints throughout production. | Minimal in-house testing, reliance on external labs if any, fewer checkpoints. |

| Customer Support & Warranty | Dedicated customer service, technical support, comprehensive warranty (e.g., 5-10 years on coatings), after-sales service. | Limited support, short or no warranty, difficult to resolve issues. |

| Experience & Reputation | Decades of industry experience, strong client testimonials, established market presence, proven track record. | Newer entrants or less established, potentially inconsistent reputation. |

| Delivery & Logistics | Efficient supply chain, global shipping capabilities, reliable delivery times, clear delivery schedules. | Less predictable delivery, limited shipping options. |

HB Hou Steel: A Trusted Partner

HB Hou Steel, with over two decades of dedicated experience in steel wire manufacturing, stands as a testament to consistent quality and innovation. Our commitment to adhering to international standards such as ISO 9001 and leveraging cutting-edge manufacturing technologies ensures that products like the Garden Wire Multipurpose Gardening Metal Wire Binding Twist Tie not only meet but exceed customer expectations for durability and performance. Our extensive experience serving diverse industries, from agriculture to construction, attests to our authoritative position in the market.

Customization Solutions and Services

Recognizing that every gardening project has unique demands, leading manufacturers offer bespoke solutions. Our Garden Wire Multipurpose Gardening Metal Wire Binding Twist Tie, while versatile, can be further tailored:

- Gauge and Length Customization: We can provide specific wire gauges (e.g., thinner for delicate seedlings or thicker for heavy vine support) and precise roll lengths to minimize waste for large-scale agricultural or landscaping projects.

- Coating Options: Beyond standard galvanized and PVC (including garden wire green), we can explore specific coating thicknesses or even alternative polymer coatings for specialized environmental conditions (e.g., coastal areas requiring enhanced salt resistance).

- Color Matching: For aesthetic or branding purposes, custom PVC colors can be matched to specific requirements, ensuring the garden wire blends seamlessly or stands out as desired.

- Packaging Solutions: From bulk industrial coils to consumer-friendly retail packaging (e.g., hang-tag spools for DIY stores), packaging can be customized to suit distribution channels and end-user convenience.

- Pre-formed Shapes or Mesh: For specific applications like tomato cages or specialized trellises, we can discuss pre-forming the garden wire into desired shapes or manufacturing custom garden wire mesh configurations to save installation time and effort on-site.

Our technical team works closely with clients to understand their specific needs, providing engineering support and recommendations to ensure the optimal garden wire solution for their application.

Real-World Application Cases & Customer Success

The true measure of any product lies in its real-world performance and customer satisfaction. The Garden Wire Multipurpose Gardening Metal Wire Binding Twist Tie has been successfully deployed in numerous projects, ranging from home gardens to commercial farms.

- Case Study 1: Commercial Vineyard Trellising. A vineyard in Napa Valley, California, replaced their old, rusting trellis system with galvanized 12-gauge garden wire from HB Hou Steel. The new system demonstrated superior resistance to the region's humid mornings and intense summer sun. The strong tensile strength easily supported heavy grape yields, leading to a 15% reduction in vine damage and an estimated 8-year extension in trellis lifespan compared to their previous solution. The ease of installation also reduced labor costs by 10% during setup.

- Case Study 2: Urban Community Garden Project. A non-profit organization establishing a community garden in Brooklyn, New York, utilized our garden wire green PVC-coated wires for vertical vegetable gardens. The green coating blended aesthetically with the urban greenery, and the smooth finish protected delicate tomato and cucumber vines. Feedback highlighted the wire's flexibility for easy training and its excellent durability against the city's varied weather, maintaining its integrity through multiple seasons.

- Case Study 3: Large-Scale Nursery Plant Support. A major plant nursery in Florida adopted the Multipurpose Gardening Metal Wire Binding Twist Tie for bundling and supporting young trees and shrubs during transport and initial growth. The convenient twist-tie design drastically sped up their bundling process by 25%, while the durable coating prevented rust despite high humidity, ensuring healthy plant delivery to customers nationwide.

Customer Testimonials:

"We've tried various garden wire brands for our organic farm, but HB Hou Steel's galvanized wire stands out. It's incredibly strong, easy to work with, and truly lasts. We haven't had to replace a single strand in three years, which saves us a ton on maintenance." - Sarah J., Organic Farmer, Oregon.

"The garden wire green PVC-coated option was perfect for our school's sensory garden. It looks natural, and the kids can safely handle it without cuts or scratches. It's been fantastic for our climbing beans!" - Mark T., Garden Coordinator, UK.

These cases underscore the product's reliability and the tangible benefits it delivers in terms of durability, ease of use, and cost-effectiveness across diverse horticultural settings.

Frequently Asked Questions (FAQ) about Garden Wire

Here are answers to some common technical questions about garden wire:

- Q1: What is the optimal gauge of garden wire for supporting heavy climbing plants like tomatoes or pumpkins?

- A1: For heavy climbing plants, a lower gauge wire (thicker wire) is recommended. Typically, 12- to 14-gauge garden wire is ideal. This provides sufficient tensile strength to support the weight of mature, fruit-laden plants without sagging or breaking. For comparison, thinner 18- to 22-gauge wires are better suited for light-duty tying or delicate vines.

- Q2: How does hot-dip galvanization (HDG) enhance the lifespan of garden wire compared to electro-galvanization?

- A2: Hot-dip galvanization (HDG) creates a significantly thicker and more uniform zinc coating (typically 60-290 g/m²) compared to electro-galvanization (usually 10-30 g/m²). This thicker layer provides a superior barrier against corrosion, extending the wire's outdoor lifespan dramatically, often by several years, making it ideal for long-term outdoor exposure.

- Q3: Is PVC-coated garden wire safe for edible plants, and what are its main advantages?

- A3: Yes, high-quality PVC-coated garden wire, like our garden wire green option, is safe for edible plants. Modern PVC formulations are non-toxic and free from harmful substances like phthalates. Its main advantages are enhanced corrosion resistance, UV stability, a smooth non-abrasive surface that prevents damage to plant stems, and aesthetic appeal due to color options.

- Q4: What specific industry standards should I look for when purchasing high-quality garden wire?

- A4: Look for manufacturers that adhere to international standards such as ISO 9001 (Quality Management System), ASTM A641/A641M (Standard Specification for Zinc-Coated (Galvanized) Carbon Steel Wire), and ISO 1461 (Hot-dip galvanized coatings on fabricated iron and steel articles). These certifications indicate adherence to strict quality control and material specifications.

- Q5: Can garden wire mesh be used for permanent fencing, or is it primarily for temporary structures?

- A5: Garden wire mesh can be used for both temporary and permanent fencing, depending on its material, gauge, and coating. For permanent installations (e.g., animal enclosures, perimeter fencing), heavier gauge, hot-dip galvanized, or even stainless steel garden wire mesh is recommended for maximum durability and corrosion resistance. Lighter gauge mesh is suitable for temporary barriers or plant supports.

- Q6: What is the significance of tensile strength in garden wire, and how does it affect its application?

- A6: Tensile strength is a critical parameter representing the maximum load a wire can withstand before breaking. Higher tensile strength means the wire can support heavier loads without stretching or snapping. This is particularly important for applications like trellising fruit trees, supporting heavy vines, or constructing structures that need to resist significant wind or plant weight. For example, a wire with 500 MPa tensile strength is considerably stronger than one with 300 MPa.

- Q7: What is the typical lead time for custom orders of garden wire, and what kind of warranty is usually offered?

- A7: For standard orders of Garden Wire Multipurpose Gardening Metal Wire Binding Twist Tie, typical lead times range from 7 to 14 business days, depending on order size and current production schedules. For highly customized solutions (e.g., specific gauges, custom coatings, or unique packaging), lead times may extend to 3-4 weeks. Reputable manufacturers like HB Hou Steel generally offer a product warranty ranging from 5 to 10 years, covering material and coating defects under normal usage conditions, demonstrating commitment to product longevity and customer satisfaction.

Reliability, Delivery, and Support

Our commitment extends beyond manufacturing. We ensure a seamless experience from inquiry to delivery. Our typical delivery period for standard garden wire products ranges from 7 to 14 business days, subject to order volume and destination. For large-scale or custom projects, we provide precise lead times upon consultation, aiming for optimal efficiency and timely project completion. Every product comes with a comprehensive warranty against manufacturing defects, typically covering 5-10 years for coating integrity and material performance, underscoring our confidence in product durability. Our dedicated customer support team is available to assist with technical queries, order tracking, and any after-sales service requirements, ensuring a trustworthy partnership.

The choice of garden wire is a foundational decision for any successful gardening project. By prioritizing quality materials, advanced manufacturing processes, and reputable suppliers, you invest in the longevity and vitality of your garden. The Garden Wire Multipurpose Gardening Metal Wire Binding Twist Tie from HB Hou Steel embodies these principles, offering unparalleled performance and reliability for all your horticultural needs.

References and Further Reading:

- Grand View Research. (2021). Gardening Market Size, Share & Trends Analysis Report. Retrieved from https://www.grandviewresearch.com/industry-analysis/gardening-market

- ASTM International. (n.d.). ASTM A641/A641M - Standard Specification for Zinc–Coated (Galvanized) Carbon Steel Wire. Retrieved from https://www.astm.org/a0641_a0641m.htm

- ISO. (n.d.). ISO 9001 Quality management. Retrieved from https://www.iso.org/iso-9001-quality-management.html

- Gardening Forum Discussion on Wire Durability. Retrieved from https://www.gardenweb.com/discussions/5267868/best-wire-for-trellis-and-plant-support-longevity (Example of a relevant forum link)