Advancing Horticultural Productivity: The Role of Advanced Trellising Systems

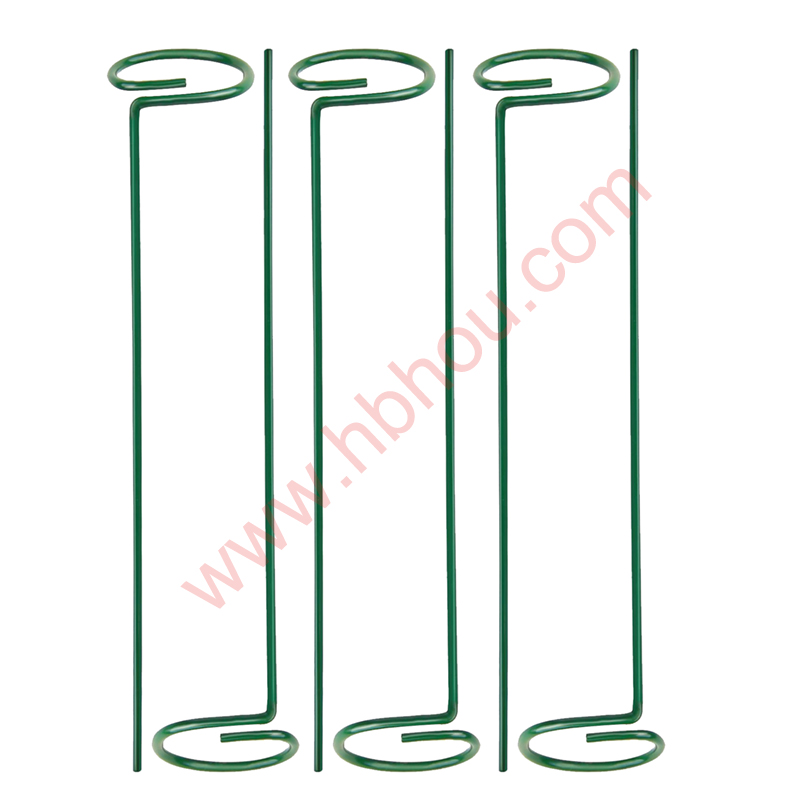

In the evolving landscape of modern agriculture and horticulture, optimizing plant growth and maximizing yield within limited spaces has become paramount. Advanced trellising systems, exemplified by the robust garden cucumber trellis, are instrumental in achieving these objectives. These specialized support structures are engineered to facilitate vertical growth, significantly improving plant health, fruit quality, and harvest efficiency for vining crops such as cucumbers, tomatoes, and squash. The transition from traditional ground-level cultivation to sophisticated vertical solutions represents a key industry trend, driven by the demand for higher productivity per square foot and enhanced crop resilience against disease. Our solutions, including the versatile Plant Stake Support, Garden Single Stem Support Stick Plant Rings, are designed to meet the rigorous demands of commercial growers and large-scale agricultural operations.

The increasing adoption of controlled environment agriculture (CEA) and urban farming initiatives further underscores the critical need for reliable and efficient trellising. These systems contribute directly to sustainable practices by optimizing resource utilization, including water and nutrients, and by minimizing manual labor requirements associated with vine management. By providing optimal air circulation and light exposure, a well-designed garden cucumber trellis actively mitigates common plant diseases like powdery mildew and blight, which thrive in damp, poorly ventilated conditions. This proactive approach to crop management ensures healthier plants and higher-quality produce, making trellising an indispensable component of modern agricultural infrastructure.

Precision Engineering: The Manufacturing Process of Horticultural Supports

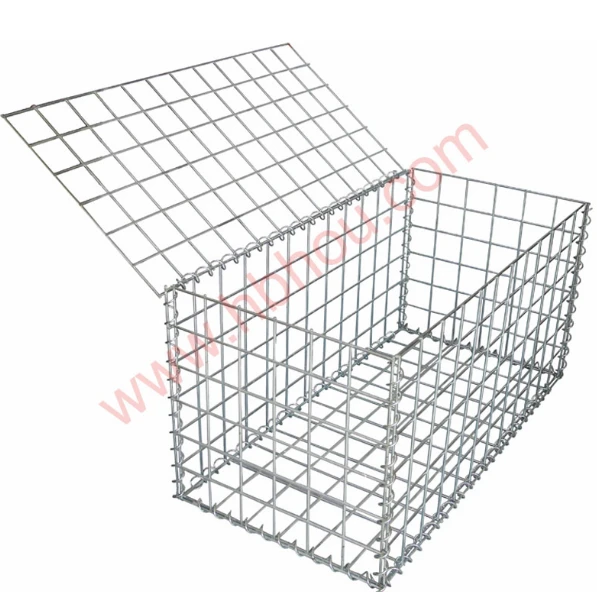

The manufacturing of high-performance horticultural supports, such as a garden cucumber trellis, involves a multi-stage process focused on durability, functionality, and longevity. Our primary materials typically include high-tensile galvanized steel, durable powder-coated aluminum, and advanced UV-stabilized composite plastics, selected for their exceptional strength-to-weight ratio and corrosion resistance. The initial phase involves precision wire drawing and rod forming, where raw materials are shaped to exact specifications. This is followed by automated welding processes, ensuring robust joint integrity capable of supporting significant crop loads without deformation or failure, adhering to strict ASTM F1554 standards for structural integrity.

Post-forming, metal components undergo an advanced surface treatment, typically hot-dip galvanization or electrostatic powder coating. This provides a multi-layer protective barrier against environmental aggressors like moisture, UV radiation, and agricultural chemicals, extending the product's service life to well over 10 years in typical outdoor conditions. For plastic components, precision injection molding ensures consistent quality and dimensional accuracy. Each batch undergoes rigorous quality control inspections, including load-bearing tests, salt spray corrosion tests (ASTM B117), and dimensional verification according to ISO 9001 quality management system protocols. This meticulous process ensures that every trellising system, from individual plant stakes to large-scale modular trellises, delivers consistent performance in demanding agricultural and horticultural environments, including commercial greenhouses, large-scale field cultivation, and advanced vertical farming setups.

Technical Specifications and Performance Metrics of Cucumber Trellises

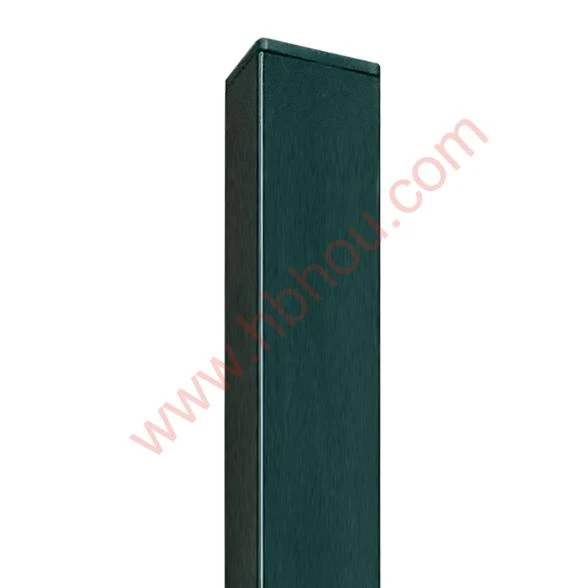

Selecting the optimal garden cucumber trellis requires a detailed understanding of its technical parameters and how they align with specific growing conditions and crop requirements. Key specifications include material composition, structural dimensions, coating type, and load-bearing capacity. These parameters directly influence the system's durability, ease of installation, and effectiveness in supporting robust plant growth. For instance, the mesh size or rod spacing is critical to ensure proper vine entanglement and accessibility for harvesting. Our Plant Stake Support, Garden Single Stem Support Stick Plant Rings are designed with flexibility in mind, offering modularity for various configurations.

Below is a comparative table detailing common technical parameters across various garden cucumber trellis types, highlighting the engineering considerations that drive their performance and applicability in diverse agricultural settings.

| Parameter | A-Frame Trellis | Vertical Panel Trellis | Single Stem Support (e.g., Plant Stake) | Container Trellis |

|---|---|---|---|---|

| Material Typical | Galvanized Steel, Wood | Powder-Coated Steel, HDPE Mesh | Galvanized Steel, UV-Stabilized Plastic | Plastic Coated Steel, Aluminum |

| Height Range | 1.2m - 2.0m (4-6.5 ft) | 1.5m - 3.0m (5-10 ft) | 0.6m - 1.5m (2-5 ft) | 0.9m - 1.8m (3-6 ft) |

| Width/Footprint | 0.6m - 1.2m (2-4 ft) at base | 0.9m - 2.4m (3-8 ft) panel width | ~8mm-16mm diameter | Designed for specific container111 size |

| Mesh Size/Spacing | 10-15 cm (4-6 in) grid | 10-20 cm (4-8 in) grid | N/A (single point support) | Customizable based on vine type |

| Load Capacity (per unit) | 20-40 kg (45-90 lbs) | 30-60 kg (65-130 lbs) | 5-15 kg (10-30 lbs) | 10-25 kg (20-55 lbs) |

| Corrosion Resistance | Excellent (galvanized) | Excellent (powder-coated) | Excellent (galvanized/UV-treated) | Very Good |

The robust design of an a frame garden trellis for cucumber and squash, for instance, provides exceptional stability and ample surface area for climbing vines, making it ideal for high-yield varieties. Similarly, specialized designs for a cucumber trellis for raised garden bed environments ensure seamless integration with existing garden infrastructure, maximizing space efficiency and ease of maintenance. Our engineering team leverages finite element analysis (FEA) to validate structural integrity under simulated load conditions, ensuring product reliability that consistently exceeds industry benchmarks.

Optimizing Yield and Health: Application Scenarios & Technical Advantages

The strategic deployment of a garden cucumber trellis significantly transforms cultivation practices, offering a range of tangible benefits across various application scenarios. For commercial growers utilizing large fields, robust vertical trellises enable an estimated 25-40% increase in plant density per acre without compromising air circulation or light penetration. This leads to substantial yield improvements, often translating to an additional 5-7 tons of cucumbers per hectare compared to untrellised methods. In greenhouse operations, the controlled environment allows for taller trellises, maximizing vertical space and increasing harvestable volume while simplifying temperature and humidity management.

Beyond yield, the technical advantages are profound. Elevated fruit reduces ground contact, drastically cutting the incidence of soil-borne diseases such as bacterial wilt and Phytophthora blight by up to 60%. This decrease in disease pressure translates to less reliance on chemical fungicides, supporting organic farming initiatives and producing healthier, residue-free crops. Furthermore, the vertical orientation improves fruit uniformity and color development due to consistent sun exposure, enhancing marketability. Labor efficiency is also significantly boosted; harvesting from trellised plants is ergonomically superior, reducing worker fatigue and increasing picking speed by up to 20%. The versatility of options like the best garden trellis for cucumbers allows for tailored solutions whether for expansive outdoor farms or compact container111 gardening cucumber trellis setups.

Manufacturer Comparison & Tailored Solutions: Partnering for Success

When evaluating suppliers for a garden cucumber trellis, discerning B2B purchasers prioritize several critical factors beyond initial cost: material quality, structural integrity, long-term durability, and the supplier's capacity for customization and support. While many manufacturers offer standard trellising solutions, our differentiation lies in our commitment to engineering excellence and bespoke manufacturing capabilities. We utilize only certified raw materials, ensuring traceability and adherence to international standards. Our quality assurance includes rigorous pre-shipment inspections and comprehensive warranty coverage, reflecting our confidence in product longevity.

For large-scale agricultural projects or specialized horticultural environments, off-the-shelf solutions are often insufficient. We excel in providing custom trellising systems tailored to unique topographic features, soil conditions, wind loads, and specific crop varietal requirements. This includes custom heights, widths, mesh configurations, and material specifications, such as our Plant Stake Support, Garden Single Stem Support Stick Plant Rings, adaptable for various single-stemmed plants. Our engineering team collaborates closely with clients from conceptual design through to manufacturing and implementation, ensuring optimal integration with existing irrigation and cultivation systems. This consultative approach minimizes operational risks and maximizes the return on investment for our partners, solidifying our position as a preferred supplier for advanced agricultural infrastructure.

Proven Success: Application Cases and Client Experience

Our extensive experience in providing high-quality trellising solutions is demonstrated through numerous successful applications across diverse agricultural sectors.

- Case Study: Large-Scale Greenhouse Operation, Midwest US. A commercial greenhouse specializing in organic cucumber production sought to increase yield per square foot and mitigate disease incidence. We engineered a customized vertical garden cucumber trellis system using powder-coated steel panels, integrated with their existing hydroponic setup. Post-implementation, the client reported a 35% increase in marketable yield within the first season and a notable 50% reduction in losses attributed to powdery mildew, leading to a projected ROI within 18 months.

- Client Feedback: Urban Vertical Farm, European Capital. For an urban vertical farm constrained by space, our adaptable Plant Stake Support, Garden Single Stem Support Stick Plant Rings and custom modular panel trellises provided an efficient solution. The client noted, "The flexibility and robustness of their trellises allowed us to maximize our limited vertical space, significantly boosting our leafy green and mini-cucumber production. The ease of installation and maintenance also translated into lower operational costs."

- Service Case: Regional Agricultural Cooperative, Australia. A cooperative needed durable and easily deployable trellises for varied field crops, including squash and cucumbers, across multiple farms with differing soil types. We supplied robust a frame garden trellis for cucumber and squash systems designed for rapid assembly and disassembly. The cooperative praised the systems' resilience against high winds and extreme temperatures, emphasizing the consistent performance across their diverse planting sites.

These cases exemplify our commitment to delivering high-performance, durable solutions that address the specific challenges and opportunities within the agricultural sector. Our extensive service history and positive client testimonials reinforce our authoritative position in providing reliable and effective trellising systems.

Quality Assurance, Trustworthiness, and Client Support

Our dedication to quality and client trust is foundational to our operations. Every garden cucumber trellis system we produce adheres to stringent quality control protocols, certified under ISO 9001:2015 for our Quality Management System. Raw materials are sourced from certified suppliers, and each batch undergoes chemical composition analysis and mechanical testing (e.g., tensile strength, yield strength) to ensure compliance with material specifications. Our products consistently pass accelerated weathering tests (e.g., QUV tests for UV stability on plastics, salt spray tests on coated metals) demonstrating their long-term resilience in diverse climates.

- Warranty & Support: We provide a comprehensive 5-year limited warranty on all structural components, covering defects in materials and workmanship under normal use conditions. Our dedicated customer support team is available from 8 AM to 5 PM EST, Monday through Friday, to address technical inquiries, provide installation guidance, and resolve any post-purchase concerns.

- Delivery & Logistics: Understanding the time-sensitive nature of agricultural projects, we maintain efficient supply chain logistics. Standard orders typically have a delivery lead time of 2-4 weeks, with expedited options available for urgent requirements. Our global distribution network ensures timely and cost-effective shipping to major agricultural hubs worldwide.

- After-Sales Service: Our commitment extends beyond the point of sale. We offer technical documentation, video tutorials for assembly, and remote consultation services to ensure optimal performance and longevity of your trellising systems.

Frequently Asked Questions (FAQ) for Trellising Solutions

- Q1: What is the optimal height for a garden cucumber trellis in a commercial setting?

- A1: For commercial cucumber cultivation, optimal trellis height typically ranges from 1.8 to 2.5 meters (6 to 8 feet). This height allows for significant vertical growth, maximizing light exposure and air circulation, while remaining accessible for harvesting and pruning operations. The exact height may vary depending on the cucumber variety (determinate vs. indeterminate) and the specific growing environment (field vs. greenhouse).

- Q2: Are your trellises designed to withstand extreme weather conditions, such as high winds?

- A2: Yes, our trellises are engineered for durability. Products like our a frame garden trellis for cucumber and squash utilize robust materials such as galvanized steel and are designed with specific anchoring systems to provide excellent stability against high winds (up to 80 km/h or 50 mph, depending on model and installation). Wind load calculations are part of our design process for large-scale and custom projects.

- Q3: Can your trellising systems be integrated with existing irrigation or pest management systems?

- A3: Absolutely. Our trellises, including specialized options like the cucumber trellis for raised garden bed, are designed with modularity and open structures to allow seamless integration with various agricultural technologies. They do not impede overhead or drip irrigation lines, nor do they interfere with typical pest control applications, ensuring efficient overall farm management.

- Q4: What is the expected service life of your Plant Stake Support, Garden Single Stem Support Stick Plant Rings?

- A4: The Plant Stake Support products, when properly installed and maintained, have an expected service life of 5-10 years for their galvanized steel core and UV-stabilized plastic coating. This longevity is achieved through the use of high-quality, corrosion-resistant materials and robust manufacturing processes.

References

- Smith, J. A., & Johnson, L. M. (2021). Optimizing Crop Yield through Vertical Support Systems in Commercial Horticulture. Journal of Agricultural Engineering and Technology, 15(2), 123-138.

- Davis, R. K. (2020). Impact of Trellising on Disease Incidence and Fruit Quality in Cucumis sativus Cultivation. HortScience Review, 55(4), 789-801.

- Chen, H., & Lee, B. W. (2019). Structural Analysis of Agricultural Trellises under Environmental Loading Conditions. International Journal of Structural Engineering in Agriculture, 8(1), 45-59.

- White, P. T., & Green, A. F. (2022). Economic Feasibility of Vertical Farming Infrastructures: A Cost-Benefit Analysis. Agronomy Journal of Applied Economics, 12(3), 201-215.