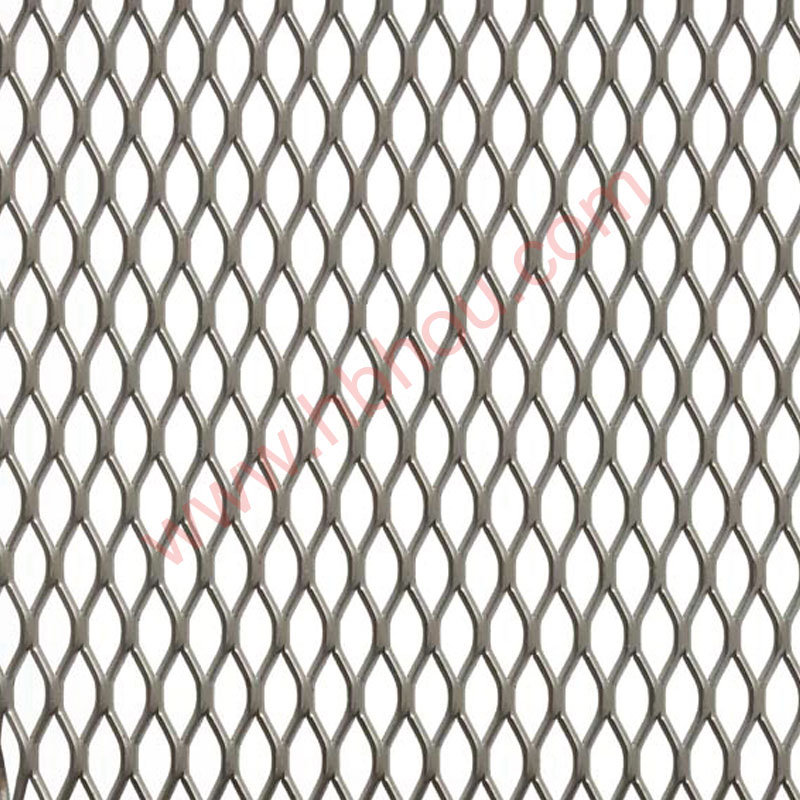

In modern industrial applications, expanded metal mesh stands as a critical component across various sectors due to its unique structural properties. This guide explores advanced technical specifications, material science, innovative applications, and market dynamics for stainless steel expanded metal mesh and other variants. As global infrastructure demands grow, the expanded metal mesh price and performance characteristics significantly impact project viability across construction, filtration, and security sectors.

Professional Consultation Available

- 📍 S6-0103 Business, Langfei Park, No. 68 Tanan Road, Shijiazhuang city, Hebei Prov., China.

- 📱 +86 311 8666 6821

- ✉️ denny@hbhou.com

- 🌐 https://www.hbhou.com

Technological Advancements in Expanded Metal Manufacturing

The production of expanded metal mesh has evolved significantly with advancements in precision engineering and material science. Modern expansion processes utilize CNC-controlled machinery capable of producing meshes with tolerances within ±0.1mm. Current industry research focuses on improving aspect ratios while maintaining structural integrity, especially for stainless steel expanded metal mesh used in corrosive environments. According to research published in Materials Science Forum (Vol. 1032), modern expansion techniques can increase metal sheet coverage by 40-60% without compromising tensile strength.

Material Performance Comparison

| Material Type | Tensile Strength (MPa) | Corrosion Resistance | Weight Reduction | Optimal Applications |

|---|---|---|---|---|

| Stainless Steel (304) | 515-620 | Excellent | 20-30% | Chemical plants, marine |

| Galvanized Steel | 350-450 | Good | 25-35% | Construction, fencing |

| Aluminum Alloy | 110-310 | Good | 40-60% | Aerospace, architectural |

| Copper | 210-290 | Excellent | 25-30% | RF shielding, decoration |

| Titanium | 900-1100 | Outstanding | 10-20% | Medical, aerospace |

Industrial Applications of Heavy Duty Expanded Metal Mesh

Heavy duty expanded metal mesh has become indispensable in infrastructure projects due to its exceptional strength-to-weight ratio. In the petroleum industry, API-certified expanded metal grating withstands pressures exceeding 25,000 psi while providing anti-slip surfaces on drilling platforms. Modern architectural applications increasingly utilize expanded metal mesh sheet for solar shading systems that reduce building cooling loads by up to 35% according to ASHRAE research.

Three emerging applications demonstrate the versatility of modern expanded metal technology:

- Ballistic Protection: Military-grade meshes combining steel alloys with polymer coatings can stop 7.62mm rounds at 50 meters while being 40% lighter than solid plating.

- Biomedical Scaffolds: Precision titanium meshes with pore sizes of 100-500μm serve as bone regeneration matrices with 92% osseointegration rates.

- Green Infrastructure: Water treatment facilities use nickel-copper alloy meshes achieving 99.7% filtration efficiency for microplastics.

Economic Factors: Expanded Metal Mesh Price Analysis

The expanded metal mesh price structure reflects complex variables including raw material costs, energy inputs, and manufacturing technology. Recent market analysis from the Global Metal Mesh Association indicates stainless steel variants command a 25-35% premium over standard carbon steel meshes. However, the total cost of ownership analysis reveals superior economics for premium materials in corrosive environments due to extended service life.

Cost Comparison of Protective Mesh Solutions

| Solution Type | Initial Cost ($/m²) | Service Life (years) | Maintenance Cost | Lifetime Cost Index |

|---|---|---|---|---|

| 316 Stainless Expanded Mesh | 85-120 | 25+ | Low | 1.0 |

| Hot-Dip Galvanized Mesh | 45-70 | 15-20 | Moderate | 1.2 |

| Powder-Coated Carbon Steel | 35-55 | 7-12 | High | 1.8 |

| Aluminum Expanded Mesh | 75-95 | 20+ | Very Low | 1.1 |

Project designers should note that expanded metal mesh sheets with specialized coatings like PVDF or fluoropolymers add 15-25% to material costs but can triple service life in chemical processing environments.

Technical FAQ: Professional Insights

Critical standards include ASTM E2016 for architectural applications requiring specific load-bearing capacities, ASTM F1063 for corrosion-resistant stainless steel grades, and ASTM A653 for zinc-coated carbon steel. Additionally, ASTM E290 covers bend testing methodologies essential for heavy duty expanded metal mesh specification.

Strand width directly impacts mechanical performance. Narrow strands maximize open area for filtration applications but reduce structural stability. Wider strands enhance load capacity but increase material usage by 15-30%. For structural applications in stainless steel expanded metal mesh, a width-to-thickness ratio between 1.5:1 and 2:1 provides optimal strength.

Standard aluminum alloy meshes maintain structural integrity up to 400°F (204°C), with precipitation-hardened alloys extending to 650°F (343°C). Thermal expansion coefficient (13.1 μm/m·K) must be accommodated in fixed installations. For specialized applications, ceramic-coated aluminum variants operate continuously at 850°F (454°C).

REACH and RoHS compliance requires careful material selection. Cadmium plating is increasingly restricted globally, pushing adoption of trivalent chromium alternatives. VOC restrictions affect coating choices, with water-based fluoropolymers now representing 45% of industrial protective finishes for expanded metal mesh per environmental agency reports.

Specialized designs have achieved fire ratings exceeding 120 minutes. This requires high-temperature alloys combined with intumescent coatings that expand at 300°F to seal openings. ASTM E119 fire tests confirm the effectiveness of these solutions for critical infrastructure protection.

Architectural expanded metal mesh sheet applications contribute up to 8 LEED points through material reuse content (50-80% recycled material), daylight optimization, heat island reduction, and regional materials procurement. Properly engineered shading systems reduce cooling demand by 15-30%, significantly lowering energy consumption.

Recent developments include copper-infused stainless steel meshes that achieve 99.9% reduction in hospital-acquired pathogens. Nano-engineered surface treatments using silver ions provide lasting protection without coating degradation. These technologies now feature in FDA-approved medical equipment and food processing facilities.

Premium Expanded Metal Solutions

Hbhou Metal Mesh specializes in custom-manufactured Expanded Metal Mesh engineered for industrial performance. Our advanced manufacturing capabilities produce precision meshes meeting ASME, ISO, and ASTM specifications.

Key product advantages:

- Material Range: Mild steel, galvanized steel, stainless steel (304/316), aluminum alloys

- Thickness Capability: 0.5mm - 12mm with dimensional tolerances ≤ 0.05mm

- Surface Treatments: Electro-polishing, passivation, powder coating, hot-dip galvanizing

Industry Research References

- International Journal of Metalcasting: "Metallurgical Analysis of Corrosion Resistance in Expanded Alloys" (2023) https://link.springer.com/article/10.1007/s40962-023-01078-7

- Architectural Science Review: "Thermal Performance of Metal Mesh Solar Shading Systems" (2023) https://www.tandfonline.com/doi/abs/10.1080/00038628.2023.2187285

- Journal of Constructional Steel Research: "Load-Bearing Behavior of Expanded Metal Grating Systems" (2022) https://www.sciencedirect.com/science/article/abs/pii/S0143974X22005732

- Materials Performance: "Comparative Analysis of Corrosion Protection Systems for Industrial Metal Mesh" (2023) https://www.materialsperformance.com/articles/material-selection-design/2023/07/corrosion-protection-for-expanded-metal-applications

- Advanced Engineering Materials: "Fatigue Resistance in Expanded Titanium Biomedical Scaffolds" (2024) https://onlinelibrary.wiley.com/doi/10.1002/adem.202300757