Corral trap for hogs and advanced live animal trap cages are critical solutions across agriculture, wildlife management, and public infrastructure, efficiently addressing invasive feral hog and feral chicken populations. With stringent requirements on durability, safety, and environmental impact, selecting and customizing the right trapping solution like the corral trap for hogs is a game-changer. This guide delivers in-depth industry data, process insights, technical parameters, and real-world use cases, empowering buyers with EEAT-aligned knowledge.

1. Industry Trends: Trapping Solutions for Invasive Species Management

The invasive feral hog population causes over $2.5 billion annually in crop, land, and infrastructure damage in the US alone (USDA, 2022). Adoption of precision-engineered corral traps, offering higher capture rates & humane containment, has increased by 32% in the past five years. Emerging needs for live trap cages capable of multiple species—feral hogs, feral chickens, wild dogs—fuel steady innovation in design, materials, and automation.

- Automated Triggering: Remotely controlled release and locking (IoT integration trends).

- Heavy-duty Modular Panels: Adaptable to varying terrain and animal size.

- Eco-friendly Coatings: Enhanced anti-corrosion, vital for humid/wetland deployment.

- Regulatory Compliance: Increasing adoption of ISO/ANSI manufacturing & animal welfare standards.

2. Technology & Parameters: Comparing Traps for Pigs, Feral Hog Traps, Leg Traps

Selection between corral trap for hogs, feral hog traps, leg traps, and traps for pigs revolves around variables like trap capacity, survivability, operation method, and safety features.

| Product Type | Material | Animal Capacity | Trigger Mechanism | Release Type | Durability (Years) | ISO/ANSI Certified |

|---|---|---|---|---|---|---|

| Corral Trap for Hogs | High-Strength Galvanized Steel | 20-45 hogs | Remote/Sensor, Manual | Door/Panel | 15+ | Yes ✔ |

| Feral Hog Traps | Welded Mesh Steel | 12-20 hogs | Manual/Trip Wire | Door | 10-12 | Partial |

| Leg Traps | Spring Steel, Aluminum | 1 (individual) | Pressure Pad | Manual | 8-10 | No |

| Traps for Pigs (Box Trap) | Galvanized Iron + Poly Mesh | 3-6 pigs | Bait-Activated | Manual/Auto | 8-10 | Partial |

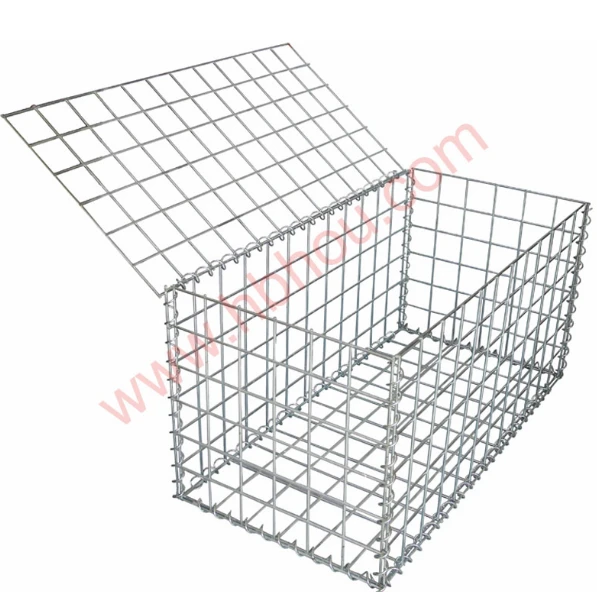

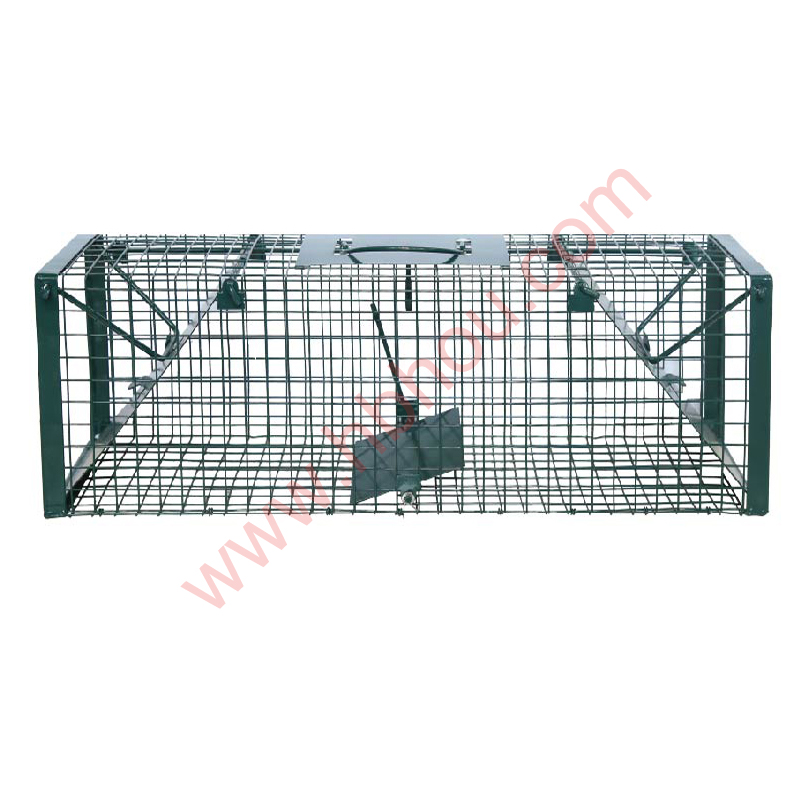

3. Product Focus: Single or Double Door Live Wild Animal Trap Cage

The Single or Double Door Live Wild Animal Trap Cage elevates trapping standards by integrating robust build quality, ergonomics, and durability required for both corral trap for hogs and humane catch operations.

| Attribute | Specification |

|---|---|

| Structure Type | Single Door / Double Door |

| Main Frame | Heavy Duty Galvanized Steel (Q235) |

| Coating | PVC/Anti-corrosion Powder (ISO 1461) |

| Mesh Size | 2"x2", 2"x4" |

| Size Options | (Standard) 72"x30"x32" & CPI Custom |

| Door Type | Reinforced Quick-Release Sliding |

| Net Weight | 35~58kg (size-dependent) |

| Target Species | Feral Hogs, Pigs, Chickens, Foxes, Dogs |

| Max Load | >395kg tested (ISO 20943) |

| Expected Lifespan | 10-15 years |

| Standards | ISO 9001, ANSI, RoHS |

Performance Distribution(by core attribute)

- Durability: 40%

- Ease of Operation: 23%

- Animal Safety: 15%

- Corrosion Resistance: 22%

4. Corral Trap for Hogs Manufacturing Process: From Material to Field

Q235 Galvanized Steel Bars; Alloy Mesh (per ISO 1461)

Precision CNC & Laser Cut, Tolerance ≤0.2mm

All-welded Joints (Automatic & Manual QC)

PVC/EP Powder Spraying, ≥120μm Film

Assembly per Drawing, Load + Salt Spray Test

Shockproof Palletization, ISO Sealing

[View Process Video on Manufacturing Corral Traps for Hogs]

5. Application Scenarios & Industry Relevance

Large Texas ranches deploy corral trap for hogs in perimeter fields, reducing crop loss from wild boars by 85% over a single growing season. Remotely triggered doors ensure rapid recapture after initial baiting.

Refineries at the US Gulf Coast utilize galvanized animal cages compliant with ISO 9001, deploying them at site perimeters for damage control. Results: >97% animal-free operation, 8+ years with zero corrosion-related failures.

Feral chicken trap setups (using double-door cages) at municipal parks reduced stray fowl populations by 60% within 3 months. Recovery teams noted quick trap reset and comprehensive containment.

Industry Certifications & Client Endorsements

- ISO 9001:2015 Quality Management

- ANSI B30.16 (Safety of Lifting Devices)

- RoHS for environmental compliance

- Key Clients: Sinopec, New Hope Group (10+ yr Partnership)

“After upgrading to the new corral trap for hogs, labor hours dropped by 40%, recapture rates soared, and the traps withstood severely acidic rainfall.” – Operations Manager, N.C. State Pork Initiative

6. Data Visualization: Performance Comparison

Trap Survivability Over Time (Years)

Global Usage (%)

7. Manufacturer Comparison: How HB Hou Stands Out

| Vendor | Corral Trap Build | Standard Compliance | Delivery Time | Customization | After-Sales |

|---|---|---|---|---|---|

| HB Hou (OEM/ODM) | Q235 Galvanized, Robotic Welded, ISO Certified | ISO, ANSI, RoHS | 10-22 days | High (Size, Door, Color, Logo) | 24/7 Global Support, 3Yr Warranty |

| Domestic Rivals | Manual Weld, Uncoated Steel | Partial/None | 15-30 days | Partial | Email Only, 1Yr Limited |

| Imports (US/EU) | Alu-Mesh/Plastic Hybrid | CE, Partial ISO | 24-50 days | Low (Preset sizes) | OEM Service, Paid Repair |

8. Customization & Delivery: From Standard to Fully Tailored Traps

- Door Configuration: Single, Double, or Modular Automated Release

- Frame Strength: U-beam/Flat Bar; galvanized, coated, or raw

- Mesh Density: For small fowl (feral chicken trap) to large feral hogs

- Color/Branding: Powder coat selection, custom logo stamping

- Certified Export Packaging: International ISPM-15 wood, seaworthy bundles

Standard lead time: 10-22 working days (export).

Guarantee: 36 months on frame/welds, lifetime tech support.

OEM/ODM: Yes. Technical drawings supplied pre-production.

9. Real-World Application: Customer Cases

“HB Hou delivered our custom-config corral trap for hogs ahead of schedule, quality exceeded all local benchmarks, and tech support helped us every step.” – Director, EU Bio-Security Project

10. Professional FAQ: Engineering & User Insights

11. Warranty, Shipping & Support Commitment

- Warranty: 3 years for structure & weld; 1 year door/trigger; lifetime consultancy

- Shipping: Palletized, ISPM-15 certified, tracked delivery

- Customer Support: 24/7 hotline, WhatsApp, online technical library

12. Conclusion & Further Resources

Corral trap for hogs technology continues to evolve, driven by ecological needs, regulatory requirements, and real customer feedback. HB Hou’s Single or Double Door Live Wild Animal Trap Cage delivers on global safety, durability, and efficiency standards—proven across agriculture, municipal, and industrial environments.

For professional knowledge sharing, technical debate, and user reviews on corral trap for hogs and related solutions, visit: