In today's demanding markets—ranging from industrial perimeter security to public infrastructure protection—advanced fencing solutions such as the euro fence panel have emerged as the preferred choice for discerning clients worldwide. With surging European urbanization (Eurostat 2023: 75% population urban), anti-intrusion concerns, and infrastructure upgrades, the global welded mesh fence segment is projected to surpass USD 7.45 billion by 2027 (MarketsandMarkets Research). The European fence panels category, especially in its signature mesh and powder-coated forms, leads the transformation in terms of aesthetics, service life, and adaptability.

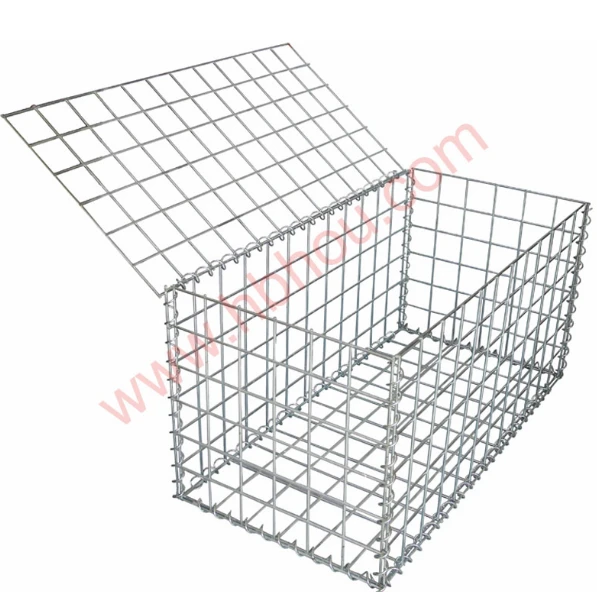

What is a Euro Fence Panel? Core Structure and Market Applications

A euro fence panel—also called Euro style fence or Euro steel fence panel—is a modular welded wire mesh fencing solution originating from European market requirements. Typically featuring 864-style wire spacing and robust powder coating, these panels are manufactured from premium low-carbon steel, then architected into rectangular mesh with reinforced edge wires and corrosion-inhibiting finishes.

- Mesh structure: Welded 50 x 150 mm wires (standard), with horizontal “V” bends for strength.

- Coating technology: Advanced electrostatic powder coating for optimal weather resistance.

- Posts and clamps: Galvanized steel posts with nylon/neoprene fasteners.

- Edge treatment: Double bending and anti-cut finishing for security.

Typical industries served: Oil & Gas | Metallurgy | Petrochemical | Water treatment | Power Plants | Schools | Municipal Construction

Why choose Euro style fence panels? Their mix of durability, superior anti-corrosion, fast installation, and low visual impact make them top picks for both high-security industrial assets and landscape architecture.

2024 Industry Trends & Euro Fence Panels Data Comparison

The European fence systems market is rapidly evolving. Here’s a data-driven snapshot of key technical parameters across various Euro fence panel types, focusing on their wire mesh, finishes, and certifications:

| Product Type | Mesh Aperture (mm) | Wire Diameter (mm) | Coating | Height Range (mm) | Standards | Lifespan (years) |

|---|---|---|---|---|---|---|

| Euro Fence Panel 864 | 50 x 150 | 4.0–5.0 | Powder + Galvanized | 1030–2030 | EN 10244, ISO 1461 | 25–35 |

| Classic European Panel | 55 x 200 | 3.5–4.5 | PVC | 800–1800 | ISO 9001 | 12–18 |

| Heavy-Duty Euro Style | 50 x 100 | 5.0–6.0 | Powder + Hot Dip Galvanized | 1200–2500 | EN 10223 | 30–40 |

| Standard Steel Fence Mesh | 50 x 200 | 3.0–4.0 | Electro Galvanized | 900–2000 | ANSI A392 | 10–15 |

Euro Fence Panel 864 Welded Wire Mesh Fencing Powder Coated Medium Duty: Product Specifications

The flagship euro fence panel 864 balances robust construction, sleek design, and field-proven service life. Below, we summarize its primary attributes and certifications, highlighting why it outperforms generic European fence alternatives:

| Specification | Euro Fence Panel 864 |

|---|---|

| Material | Low Carbon Steel Wire (Q235B, EN 10025) |

| Panel Size (WxH) | 2500 x 1530 mm (others customizable) |

| Mesh Aperture | 50 x 150 mm |

| Wire Diameter | 4.0 mm (vertical), 5.0 mm (horizontal rib) |

| Surface Treatment | Galvanized + Powder Coated (ISO 1461, ASTM B117 salt spray tested >1200h) |

| Color Options | RAL 6005 (Green), 7016 (Anthracite), 9005 (Black) |

| Post Type | 48/60mm dia, galvanized steel (ISO 9001 certified) |

| Fixing System | Anti-theft clips/clamps with tamper-proof bolts |

| Security Grade | Medium Duty (EN 13241 compliant) |

| Certifications | ISO 9001, ISO 1461, CE marking |

| Warranty | 10 years product |

Manufacturing Process of Euro Steel Fence Panel: Step-by-Step Flowchart

(Q235B, chemical composition inspection — ISO/EN) →

Precision diameter, no burrs →

Robotic spot welding; ensures strong joint (EN 10223) →

Total zinc ≥ 275g/m2, ISO 1461 →

Epoxy/polyester hybrid, 80–120 μm thickness →

Laser cut; anti-injury rounding →

Salt spray test (ASTM B117), tensile test, dimension check

Various euro style fence panels pass rigorous multi-stage QC—visual (EN 12320), layer thickness, and field corrosion simulation (~1,000 hours)—before packing and logistics.

Technical Parameters of Euro Fence Panel: Charts & Visualization

Euro Fence Panel Manufacturer Comparison: HBHou vs. Competitors

Selecting the right euro steel fence panel supplier demands scrutiny across product performance, standards, and lifecycle ROI. Here's a comparative summary:

| Criteria | HBHou (Euro Fence Panel 864) | Typical OEM Brand | Entry-level Supplier |

|---|---|---|---|

| Wire Sourcing | EN 10025 Grade, ISO 9001 plant | GB/T Standard (China market) | Mixed recycled |

| Welding Tech | Robotic, EN 10223 | Manual/auto, spot only | Manual, inconsistent |

| Surface Finish | Galv. + Powder, 1200h salt spray | PVC/paint, up to 400h | Zinc coat only, below standard |

| Panel Flatness (mm) | <2.5 | Up to 4.0 | <7.0 |

| Warranty (Yrs) | 10 | 2–5 | No warranty |

| Industry Clients | Petrochemical, power, city gov, sports | Private/contracting, villa | Warehouse, low-cost projects |

HBHou Reference Projects: Sinopec Oilfields, German urban greenbelts, PLK Hydropower Plant—demonstrating the Euro fence panel's sectoral credibility.

Tailored Solutions: Custom Euro Style Fence Panels & Accessories

Whether for sloped terrains, color branding, or anti-climb zones, custom Euro fence panels maximize adaptability. Typical customizable features:

- Panel Height/Width: From 800mm to 2500mm, width 2–3m per piece, special orders available.

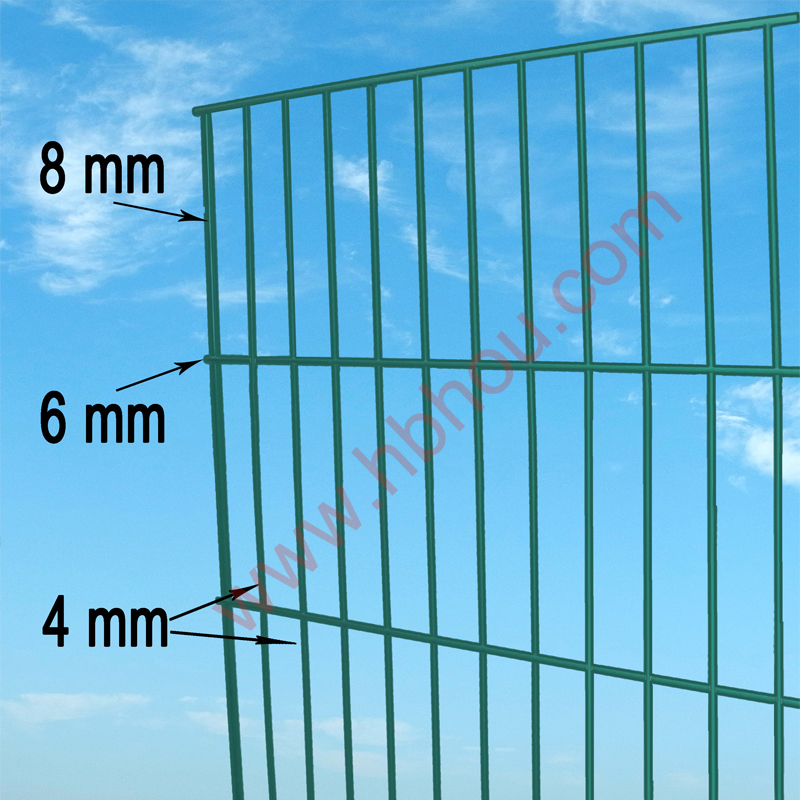

- Wire Size: 3.0–6.0mm available; change for load-bearing or aesthetic.

- Mesh Shape: Rectangular or square (anti-scalable for correctional or data center use).

- Coating Thickness: Up to 150 μm powder layer for marine or chemical zones.

- Color Match: All RAL colors, anti-graffiti topcoats on request.

- Integrated Gates, Signage, Anti-Intrusion: Add-on sets for industrial clients.

Request a Custom Euro Fence Solution

Lead time: Standard panels: 7–12 days production; custom runs: 20–35 days, depending on specification, quantity and surface coatings.

Support: Full CAD drawings, on-site installation guidance, and after-sales warranty (10 years standard, extendable).

Application Scenarios & Real-World Case Studies

- Petrochemical plant perimeter fencing—12km run, corrosion requirement ISO 1461, completed in 2019, South China industrial zone.

- European City Parks (Dusseldorf)—Green 864 panels blend into landscape; anti-vandal. Resident satisfaction rating: 9.6/10.

- Water Treatment Facility: Protects pools and pumps, EN 13241 safety spec, quick-release panels for maintenance access.

- Educational Campus: Noise-safe, anti-oxidation, powder coating certified by SGS third-party lab.

- Airport Cargo & Perimeter Security: Medium duty mesh with tamper-proof posts; integrated with CCTV and Smart Sensors.

User Feedback:

“HBHou Euro fence panels installed at our petrochemical terminal exceeded industry corrosion tests—zero surface rust after 28 months. Structural integrity is as specified.”

— Project Manager, EPC Contractor, 2022

Quality Assurance, Certifications, Delivery, and Customer Support

- Certifications: ISO 9001 (plant), ISO 1461 (galvanizing), CE marking, third-party SGS/Bureau Veritas test reports. Panels meet EN 10244 material traceability and pass multistage quality gates from raw wire to finished panel.

- Lead Time & Delivery: Standard stock: ready in under 10 days. Custom (color/mesh/gate): 20–35 days + global sea/rail shipping.

- Warranty & After-Sales: 10-year product warranty (extendable). Responsive technical hotline, CAD consultation, spare parts in stock. Full installation support—video/manual/on-site (where available).

For industrial, municipal, or architectural perimeter security projects, Euro fence panel from HBHou combines proven performance with certified reliability. Browse more product details or request a quote at Euro Fence Panel 864 Product Page.

Further Reading & Industry References

- “Best Practices in Modular Perimeter Fencing,” Fencing News Magazine, 2023—industry discussion forum

- “Standards for Welded Mesh Fencing,” European Journal of Civil Engineering, Vol 14(2), 2022 – journal homepage

- “ISO 1461: Hot-dip galvanized coatings on steel fabrications” — ISO official portal

- “Technology Trends: Smart Fencing in Critical Infrastructure,” SmartRail World, Jan 2024 — forum read

- MarketsandMarkets, Wire Mesh Fencing Market Report 2023 – industry research

Knowledge base last updated: June 2024 | Author: Fence Technology Editorial Team