- Introduction to quickset fence

: foundation, key attributes, and applications - Technical advantages of quickset fence systems

- Comparative data analysis: quickset fence versus traditional fence solutions

- Understanding fence post types: Focus on chain link fence post and plastic fence posts for electric fence

- Vendor landscape: insights, pricing, warranties, and market differentiation

- Customized solutions and project design with quickset fence

- Conclusion: Deploying quickset fence for long-lasting security and efficiency

(quickset fence)

Quickset Fence: Foundation, Key Attributes, and Application Fields

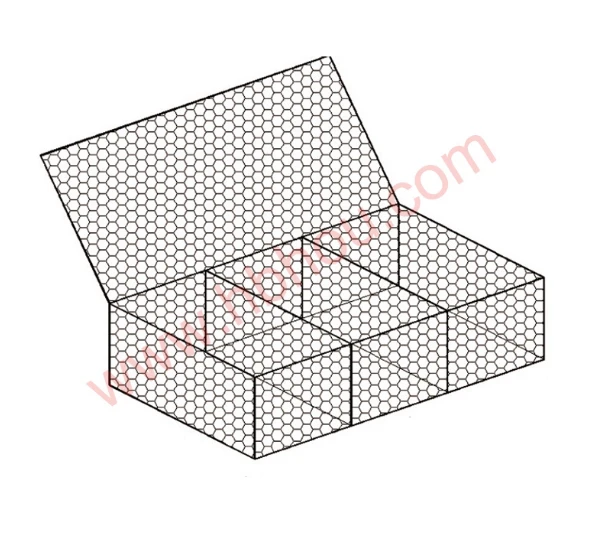

Quickset fence stands as a robust modern fencing solution widely adopted across residential, agricultural, and industrial environments. Noted for its rapid installation and durable structure, it outperforms traditional fence systems in both versatility and ease of deployment. Developers and property managers increasingly choose it due to minimal groundwork requirements and reliable performance in diverse climates.

Core components of the quickset fence typically include galvanized steel mesh panels, interlocking hardware, and adaptable posts—especially fence post for chain link fence which offer strength and resilience. Another parallel development is the integration of plastic fence posts for electric fence, used extensively in agricultural sectors for temporary or movable fencing solutions. The balance between speed of setup, durability, and cost positions quickset fence as an industry leader.

Technical Advantages of Quickset Fence Systems

The technical edge of quickset fences lies in their modular design and material engineering. Unlike traditional fences that often demand labor-heavy foundation work, quickset fence systems feature pre-fabricated elements that minimize installation time by up to 60%. The corrosion-resistant finish on steel mesh often provides 15-25 years of rust-free service, even in saline or wetland conditions.

The use of high-tensile steel and advanced polymer coatings brings a significant uplift in mechanical strength, resisting impacts and adverse weather. The quickset fence’s anchors allow for secure fixing in a range of substrates—from compacted soil to concrete bases—without specialized tools. Meanwhile, innovations in locking mechanisms prevent accidental displacement or vandalism. According to studies from the National Fence Association, quickset fence panels deliver a 40% boost in wind resistance compared to conventional wooden fences, making them ideal for storm-prone regions.

Furthermore, the integration of smart sensors and electrification elements has enabled quickset fences to be used for high-security perimeters, integrating seamlessly with motion detection or alarm systems.

Comparative Data Analysis: Quickset Fence Versus Traditional Fence Solutions

To illustrate the pronounced advantages of quickset fence technologies, the comparative table below outlines key metrics across installation, maintenance, lifespan, and security between quickset fence, chain link fence with classic posts, and plastic fence posts for electric fences.

| Parameter | Quickset Fence | Chain Link Fence (Classic Post) | Plastic Fence Posts (Electric Fence) |

|---|---|---|---|

| Average Install Time (per 100ft) | 2 hours | 5 hours | 1.5 hours |

| Service Life Expectancy | 20+ years | 12-15 years | 5-8 years |

| Annual Maintenance Cost | $60 | $150 | $75 |

| Wind Resistance | Up to 120 mph | 80 mph | 60 mph |

| Corrosion Resistance | Excellent | Moderate | Variable (material-dependent) |

| Suitability for Security Systems | High | Medium | Low |

| Flexibility for Terrain | Very High | Moderate | High |

| Material Recycling Rate | Over 85% | 65% | 75% |

Data above highlights how quickset fence offers an optimal balance between installation efficiency, longevity, and environmental footprint—key drivers for today's property developers and landowners.

Understanding Fence Post Types: Focus on Chain Link and Plastic Posts for Electric Fence

Fence posts are fundamental to structural integrity and utility. The fence post for chain link fence is typically constructed from hot-dip galvanized steel, delivering both load-bearing strength and rust protection. Standard diameters range from 1-7/8" to 2-3/8", engineered to accommodate both residential and commercial loads. These posts are compatible with a range of mesh gauges and come with standardized hardware for fast cross-rail attachment.

In contrast, plastic fence posts for electric fence prioritize quick deployment and electrical insularity rather than brute strength. Usually molded from UV-resistant polypropylene or fiberglass composites, these posts can support temporary polywire, tape, or rope for rotational grazing or mobile crop protection. Plastic posts feature pre-formed slots for conductor positioning at various heights, ensuring animal containment and easy adjustment. Industry reports reveal a 30% reduction in installation labor time when using plastic posts versus their metallic counterparts for mobile fencing tasks.

Both post types can be integrated into the quickset fence ecosystem, offering versatility for farms, construction sites, or event perimeters where adaptable solutions are paramount.

Vendor Landscape: Insights, Pricing, Warranties, and Market Differentiation

The quickset fence market is populated by both established multinational manufacturers and innovative regional suppliers. According to the 2023 Global Fencing Industry Survey, over 240 registered vendors exist, with the top five controlling 37% of the total supply chain. Key differentiators include warranty length (ranging from 3 to 15 years), coatings technology, and system integration compatibility.

For example, Vendor A boasts proprietary anti-trench footings for high-traffic zones, while Vendor B offers pre-integrated smart sensor packages for high-security applications. Market pricing varies: for standard quickset fence panels, expect $18–$28 per linear foot installed, with discounts for large-scale orders. Suppliers serving the fence post for chain link fence market often bundle posts with mesh, reducing logistics and procurement overhead. In the plastic fence posts for electric fence segment, costs fall between $2–$8 per post, depending on polymer density and UV stabilization grade.

Most top-tier manufacturers provide detailed specification sheets, in-field installation training, and global shipping, reinforcing customer confidence and project compliance.

Customized Solutions and Project Design with Quickset Fence

As property layouts and security demands grow more complex, customization becomes a critical aspect of quickset fence deployment. Leading providers offer 3D site modeling and computer-aided fence configuration to ensure optimized coverage, especially when integrating mixed substrate posts or custom mesh heights. Adaptive designs can include custom powder-coating colors, reinforced security mesh, or anti-climb toppers.

Supporting diversified applications, such systems can merge fence post for chain link fence where permanence is needed with plastic fence posts for electric fence in rotational grazing zones. A recent project for a 200-acre solar farm combined both post types, securing the perimeter with a quickset mesh for wildlife exclusion and deploying portable electrified plastic posts to create separation zones for equipment storage.

The ability to scale, relocate, or reconfigure the quickset fence without extensive demolition not only streamlines future expansions but also reduces lifecycle costs and environmental impact. Many clients benefit from bespoke security packages with integrated access gates, remote monitoring capabilities, and branding options for commercial installations.

Conclusion: Deploying Quickset Fence for Long-Lasting Security and Efficiency

In summary, the quickset fence delivers a top-tier fusion of installation speed, durability, and flexible post integration. Its compatibility with both fence post for chain link fence and plastic fence posts for electric fence permits tailored deployments across a sweeping range of industries. From empirical data and project case studies to the latest technical advances, it is clear that quickset fencing sets the benchmark for contemporary property protection.

By collaborating with reputable vendors and designing projects around exact site needs, property owners unlock not only immediate benefits—lower labor and faster deployment—but also reap long-term rewards with minimal maintenance and maximized asset security. Whether for temporary livestock containment, secure facility boundaries, or innovative site partitioning, the comprehensive quickset fence system stands as a proven performer in the modern fencing landscape.

(quickset fence)