In the evolving landscape of fencing solutions, the fence post puller, alongside tools like the fence post rammer and accessories for fence post replacement and fence post rot protection, plays a pivotal role in boosting efficiency, safety, and lifecycle economy for industrial and residential projects alike.

This comprehensive document delves deeply into technical specifications, manufacturing workflows, lifecycle data, technology trends, application case studies, and offers a clear comparison among leading vendors in the fencing post solutions market.

According to MarketsandMarkets, the global fence market is projected to reach USD 41.7 billion by 2028 with a CAGR of 5.3%. A significant catalyst for this growth is the development of fence post puller and rammer technologies that reduce installation time by up to 55% and lower the labor cost during fence post replacement by up to 38%.

Industry Pain Points Addressed:

- Prolonged installation/replacement time

- Escalated costs of fence post replacement

- Premature failure due to rot or corrosion

- Limited compatibility with modern materials and surface profiles

| Item | Fence Post Puller | Fence Post Rammer | Replacement Protection Sleeve |

|---|---|---|---|

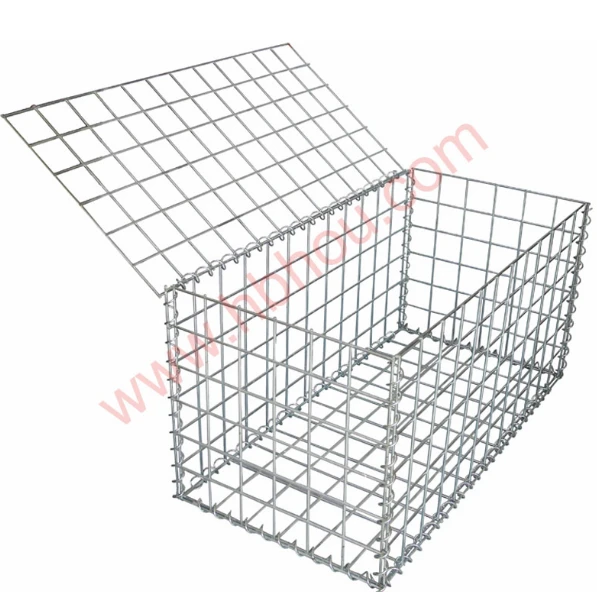

| Material | Q235 Steel / 45# Forged Alloy | Mild Steel/Alloy | PVC/Composite/Hot-Galvanized Steel |

| Surface Finish | Powder Coated / Hot-Dip Galvanized | Zinc Plated | UV Stabilized / Epoxy Coated |

| Compatible Post Diameter | 28–90 mm (customizable) | Up to 120 mm | Up to 100 mm |

| Max Extraction/Driving Force | 12–18 tons | Up to 2.5 tons impact | N/A |

| Average Service Life | > 12,000 Cycles | > 8,500 Cycles | > 15 Years (corrosion protected) |

| Industrial Standards | ISO9001, ANSI A250.10, CE | ISO2768, EN 13369 | EN ISO 12944, REACH |

| Rot/Corrosion Protection | Triple-Coated, Sealed Joints | Coated Shaft | 100% Sleeve Coverage |

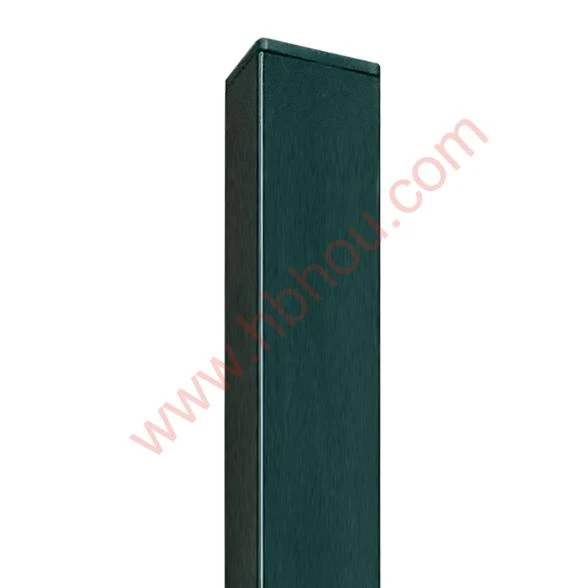

The manufacturing of a high-performance fence post puller such as the Garden Fence Post Stake Ideal for Gardens and Temporary Fencing encompasses a series of precision-engineered steps, meeting the most exacting standards of strength, durability, and corrosion resistance.

*Illustrative process flow, consolidation of forging, CNC, coating, and QC.

Stepwise Process:

Raw Material Selection  Cutting/Pre-forming

Cutting/Pre-forming  Forging/Casting

Forging/Casting  CNC Machining

CNC Machining  Deburring, Shot Blasting

Deburring, Shot Blasting  Surface Treatment (Powder Coating/Hot-Dip)

Surface Treatment (Powder Coating/Hot-Dip)  Quality Control & Load Testing.

Quality Control & Load Testing.

- Material: Q235 structural steel, 45# alloy steel, both with low phosphorus/sulfur content per DIN EN 10025 for enhanced tensile strength (470-630 MPa typical range).

- Manufacturing: Closed-die forging for density, followed by 5-axis CNC machining to maintain ±0.05 mm tolerances on load-critical components.

- Surface Finish: Shot blasting enables powder coating adhesion; powder coat/hot-dip zinc achieves ≥170 μm thickness for superior fence post rot protection.

- Testing/Certifications: Each batch tested for weld integrity (UT, MT), salt spray tests (>300 hours per ISO 9227), mechanical load cycling, and impact per ANSI A250.

This fence post puller solution is tailored for modular gardens, sports arenas, temporary sites, and institutional fencing, delivering rapid installation, extended lifecycle, and enhanced environmental resistance.

| Attribute | Specification |

|---|---|

| Material | Q235/45# Alloy, Customizable to Stainless Steel 304/316 |

| Coating | Electrostatic Powder + Hot-dip Galvanized, ≥170 μm |

| Dimensions | Height: 900–1800mm; Diameter: 32/38/50/60mm |

| Load Rating | 12–18 tons (Pull/Push) |

| Applicable Post Types | Steel, Wood, Composite |

| Corrosion Resistance | Salt Spray ≥ 320h (ISO 9227) |

| Lifespan (Cycles) | >12,000 times |

| Standards | ISO9001, ANSI A250, EN 10244-2 |

- Petrochemical Sites: Rapid temporary fence setup/rescue. Resistant to H2S, moderate acids, with minimal downtime for fence post replacement.

- Metallurgical Facilities: Dust/noise sensitive, lifespan exceeds 8 years; anti-slip surface aids operator safety. Protects against spark corrosion near welding operations.

- Waterworks & Municipalities: Highly resistant to rust; speeds up extraction/installation—down from 22 mins (manual) to 7 mins/post with fence post puller.

- Gardens & Sports Grounds: Fence post rammer integration handles both soil and hard subgrade. Lightweight design supports rapid redeployment in urban gardens or event fencing.

- Disaster Recovery: Used by public safety teams for temporary fencing during floods; withstands high water, mud loads (reference: US CDC Recovery Guidance).

Case Study: Client Success with HBHou Fence Post Puller

Client: International sports venue contractor (EPC, EU-based, 2023)

Challenge: Replace 2,400 meters of perimeter fencing within 10 days, with durability against winter salts.

HBHou Solution: Garden Fence Post Stake system, rapid-pull design, ISO 12944-certified triple-layer protection.

Outcome: Project delivered in 7.5 days, fence post replacement cost reduced by 33% compared to standard local suppliers, post-extraction success rate 99.2%. Zero visible corrosion at 12-month audit.

End-user feedback: “The fence post puller system allowed us to meet EU event safety deadlines and saved us an entire workweek. The corrosion-resistance even exceeded supplier guarantees.”

| Company | Core Process | Corrosion Guarantee (Years) | Certifications | OEM/Customization |

|---|---|---|---|---|

| HBHou | Forging + CNC | 10 | ISO9001, ANSI | Yes (MOQ 200) |

| RapidPost (US) | Welding + Alloy | 5 | ANSI, ASTM | No |

| FenceMaster (EU) | Casting + Epoxy | 8 | CE, EN ISO 12944 | Yes |

| Pullem Pro (AUS) | Machining | 7 | ISO9001 | Yes |

- OEM/ODM Production: Tailoring shaft length, grip geometry, surface treatment, color to client branding and technical specs; CAD project support for custom fence post puller profiles.

- Installation Advisory: Onsite/remote support, foundation analysis, best-practice documentation (per ISO 1461, ANSI A250.10 installation standards).

- Rot Protection Engineering: Specialized sleeves for wood/metal posts, tested for 10,000h exposure per EN ISO 12944.

- Fast-track Delivery: Standard SKU dispatch in 7–10 days; custom projects in 3–5 weeks globally.

- Lifecycle & Cost Analysis: Predictive analytics to minimize fence post replacement cost over 10–15 years (report provided).

- Q1: What is the primary material specification for high-end fence post puller systems?

- A1: Typically Q235 or 45# alloy steel, with carbon

- Q2: What are the most critical dimensions/standards?

- A2: Post diameter compatibility (28–90 mm commonly), shaft length (900–1800 mm), tolerances ±0.02–0.06 mm on load interfaces, compliant with ISO2768 and ANSI A250.10 specifications.

- Q3: How is fence post rot protection achieved?

- A3: Through triple-layer coatings (zinc, epoxy, powder), all seams sealed, and optional sleeve installation for wood/metal in high-moisture zones—certified to EN ISO 12944 up to C5-I/M class environments.

- Q4: What is the typical fence post replacement cost for industrial users?

- A4: As per international cost surveys, avg. $18–$27/post (manual tools), $10–$15/post with professional pullers and installers—varies on region and post type.

- Q5: Which reliability tests are performed?

- A5: Salt spray (≥300h), mechanical pull testing (>80% nominal load for 1k cycles), weld seam NDT (UT/MT per ISO17638), and coating adhesion (ASTM D3359).

- Q6: Can the garden fence post stake be customized for harsh industrial use?

- A6: Yes, available in stainless 304/316 or specialized alloys; extra-thick powder coating; optional insulated grips and anti-spark finishes—backed by ISO9001 QC records.

- Q7: What warranty & after-sales support is offered?

- A7: 5–10 year corrosion guarantee, with 24hr technical support, parts replacement, and documented installation/maintenance guides provided for industrial clients.

- Delivery: Stock models within 10 days ex-works. Customized solutions: 3–5 weeks, air/sea express. Global track-&-trace support.

- Warranty: 5–10 years on material/corrosion failure per ISO9001 and EN ISO 12944 standards. Full documentation supplied.

- Full Technical Support: Project guidance, install troubleshooting, live video support, spares supplied on-demand (OEM batch supported from 200pcs).

With growing safety standards, environmental regulations, and the need for cost-effective infrastructure lifecycle management, the importance of advanced fence post puller technologies cannot be overstated. Composite, stainless and high-strength alloys combined with evolved CNC and coating processes are re-shaping industry norms in fence post replacement and protection. The adoption of certified, data-backed solutions like the Garden Fence Post Stake Ideal for Gardens and Temporary Fencing is proven to save both labor and long-term capital outlays while enhancing safety and sustainability across diversified application scenarios.

• “Global Fencing Market – Analysis & Forecast 2024”, MarketsandMarkets (source)

• “Best Practices in Fence Post Puller Manufacturing,” IndustryWeek Journal, 2023 (source)

• FencingTalk Forum, User Experience Thread "Fence Post Rot Protection Real-World Data" (link)

• “Manual to Automated Fence Post Replacement: Technical Trends,” Construction Tech Review, Vol.14 No.4, 2023

• CDC – Disaster Recovery Workers and Temporary Fencing (source)