Understanding Wire Mesh Specifications A Comprehensive Guide

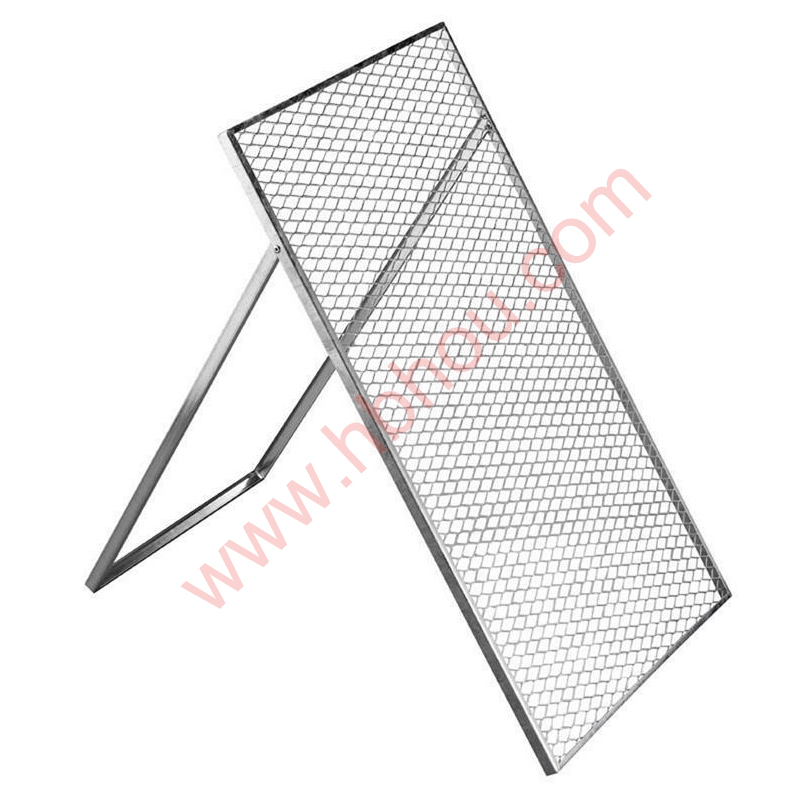

Wire mesh is a versatile material used in various industries, from construction and agriculture to manufacturing and even fine art. Its specifications play a critical role in determining the material's suitability for different applications. This article will examine the key elements of wire mesh specifications, ensuring that you can make informed decisions when selecting the appropriate type for your needs.

1. Material Composition

The first aspect to consider in wire mesh specifications is the material composition. Wire mesh can be made from a variety of materials, including stainless steel, carbon steel, galvanized steel, aluminum, and plastic. Each material has distinct properties that impact its durability, strength, corrosion resistance, and overall suitability. For example, stainless steel mesh is highly resistant to corrosion and is often used in environments that require high hygiene standards, such as food processing and pharmaceutical applications. Conversely, galvanized steel provides excellent rust resistance at a lower cost, making it suitable for outdoor construction projects.

2. Wire Diameter

The diameter of the wire used in the mesh is another critical specification. Wire diameter affects the strength, flexibility, and weight of the mesh. Thicker wires generally provide increased strength and rigidity, while thinner wires offer more flexibility and are lighter in weight. It's essential to choose the right wire diameter for your project; using a wire that is too thin may result in structural failure, whereas excessively thick wire could lead to unnecessary weight and increased costs.

Mesh opening size refers to the distance between the wires, which dictates the size of the openings in the mesh. This specification is crucial in determining the use of the wire mesh. Large openings are suitable for applications such as fencing and screening, where visibility and airflow are important. On the other hand, smaller openings are ideal for filtration applications, preventing small particles from passing through. In selecting the appropriate mesh opening size, it’s essential to consider the specific requirements of your project, including the type of materials to be filtered or contained.

wire mesh specification pdf

4. Weave Type

The weave type of wire mesh also significantly impacts its performance characteristics. Common weave types include plain weave, twill weave, and Dutch weave. Plain weave is the most common and involves the simple over-and-under pattern of wires, providing a balanced combination of strength and flexibility. Twill weave offers greater flexibility and is generally used in applications that require higher resistance to deformation. Dutch weave is often employed in filtration processes, offering superior strength and the ability to create very small openings. Understanding the implications of different weave types can help you select the most appropriate wire mesh for your application.

5. Coating and Finish

The coating and finish of wire mesh can enhance its durability and suitability for specific environments. Common coatings include PVC, polyester, and galvanization. These coatings provide added resistance to corrosion, wear, and UV exposure. When specifying wire mesh, it’s important to consider the environmental conditions in which the mesh will be used, as these factors will significantly influence its longevity and performance.

6. Applications

Wire mesh has a diverse range of applications, including construction, agriculture (e.g., animal enclosures), landscaping, security (e.g., fencing), filtration (e.g., screens and sieves), and many others. Understanding the specific application requirements is crucial to selecting the correct wire mesh specifications.

In conclusion, wire mesh specifications encompass a range of critical factors, including material composition, wire diameter, mesh opening size, weave type, coating and finish, and application suitability. By considering these factors, you can ensure that you select the right wire mesh for your project. Understanding these specifications not only helps to meet quality standards but also enhances the overall performance and longevity of the wire mesh in its intended application.