The Versatility of Wire Mesh Products Applications and Benefits

Wire mesh products have become integral components in various industries due to their versatility, strength, and reliability. Made from woven or welded wire, these products are used across numerous applications, from construction and architecture to agriculture and filtration systems. This article explores the diverse nature of wire mesh products, their manufacturing processes, and the benefits they offer.

Wire mesh is primarily crafted from materials like stainless steel, galvanized steel, aluminum, and plastic. The choice of material often depends on the specific application and the environmental conditions it will face. For example, stainless steel mesh is favored in areas susceptible to corrosion or where hygiene is paramount, such as in food processing and medical equipment. Meanwhile, galvanized wire mesh is often used in construction and industrial applications due to its strength and resistance to rust.

One of the most significant advantages of wire mesh products is their adaptability. They can be customized in terms of size, shape, and mesh pattern to accommodate a wide range of applications. In construction, wire mesh is used for reinforcing concrete structures. It enhances the tensile strength of concrete, preventing cracking and ensuring durability, making it a crucial element in the building sector. Moreover, wire mesh is essential for safety, as it provides barriers for fencing and window screens, thus protecting properties and occupants.

In agriculture, wire mesh is utilized for various purposes including fencing livestock enclosures, soil erosion control, and as a support system for plants. It allows for proper air circulation and drainage while minimizing soil erosion. The durability of wire mesh ensures that these agricultural products can withstand harsh environmental conditions, promoting sustainable farming practices.

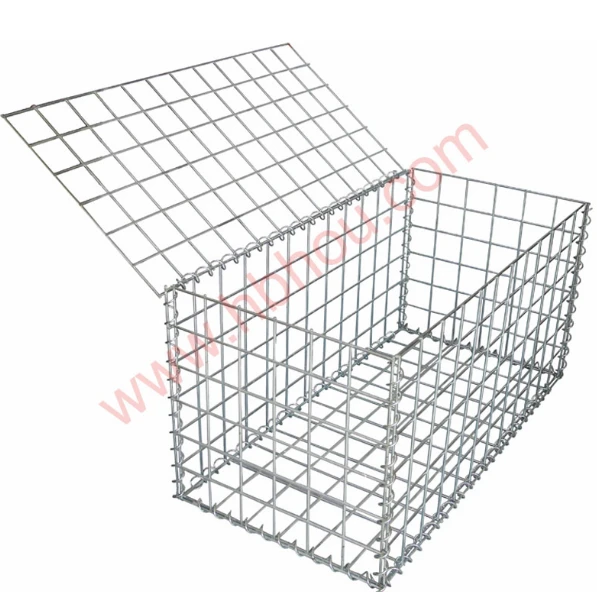

wire mesh products

Additionally, the filtration industry relies heavily on wire mesh products. Their fine mesh patterns are ideal for various filtration applications, from water purification to industrial processes. The ability to filter out particles and impurities makes wire mesh essential in maintaining the quality of liquids and gases across multiple industries. This function is particularly critical in sectors such as petrochemical, pharmaceutical, and food processing, where cleanliness and quality control are paramount.

Another noteworthy application of wire mesh is in the art and design space. Artists and designers have increasingly adopted wire mesh for creating sculptures, decorative installations, and even furniture. Its unique aesthetic appeal, combined with its structural properties, allows for innovative designs that merge functionality and artistic expression.

The manufacturing of wire mesh products involves several processes, including weaving, welding, and cutting. Automated machinery has advanced these processes, enhancing precision and reducing production time. The ability to mass-produce wire mesh without compromising quality has made it accessible for various applications.

In conclusion, wire mesh products have established themselves as essential components in multiple fields owing to their strength, durability, and versatility. From construction to agriculture and art, the applications of wire mesh are diverse and ever-expanding. With ongoing advancements in manufacturing technologies, the future of wire mesh products looks promising, continuing to meet the evolving needs of industries worldwide. Whether for practical uses or aesthetic endeavors, wire mesh will undoubtedly remain a staple material in many aspects of modern life.