Understanding Wire Mesh Price Per Square Meter

Wire mesh is a versatile and widely used material in various industries, including construction, agriculture, and manufacturing. With its numerous applications, the price of wire mesh per square meter can vary significantly based on a multitude of factors. This article aims to shed light on these factors and help consumers make informed decisions when purchasing wire mesh.

Factors Influencing the Price of Wire Mesh

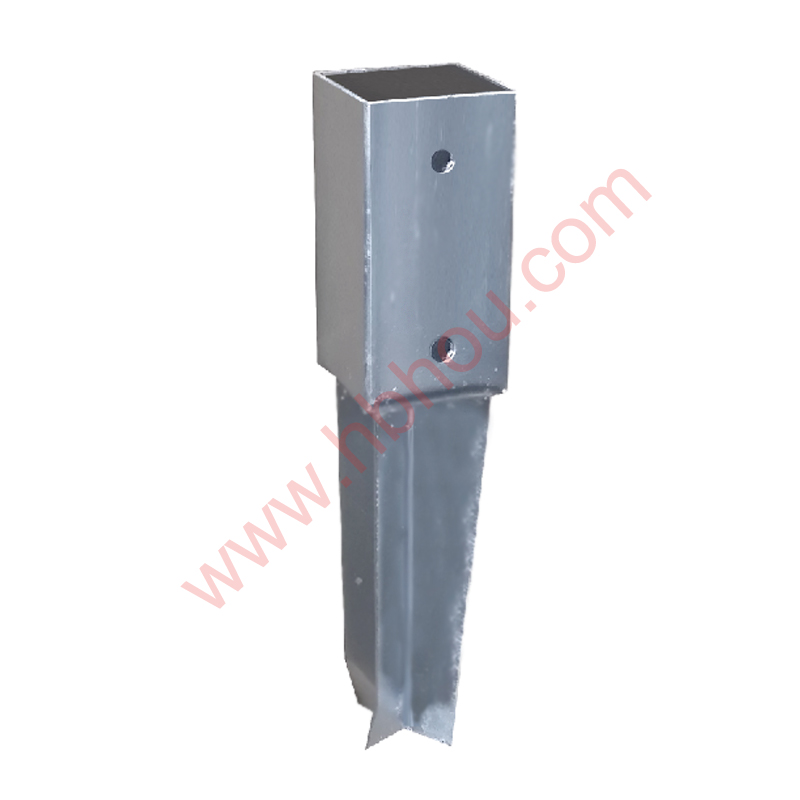

1. Material Composition The type of material used to manufacture wire mesh greatly influences its price. Common materials include stainless steel, galvanized steel, and plastic. Stainless steel is typically more expensive due to its corrosion resistance and strength. In contrast, galvanized steel, which is coated with zinc, offers a balance between cost and durability, making it a popular choice for outdoor applications.

2. Mesh Size and Aperture The size of the mesh and the diameter of the wire used also play crucial roles in determining the price. Finer mesh with smaller openings generally requires more intricate manufacturing processes and higher-quality wires, thus increasing the cost per square meter. Conversely, larger apertures can reduce the price but may not be suitable for all applications, particularly where containment or filtration is required.

3. Manufacturing Process The production method affects both the quality and price of wire mesh. Options include welded, woven, or knitted wire mesh. Welded wire mesh tends to be more robust and is often used for fencing and structural support. However, the welding process can make it more expensive compared to woven options. Understanding the intended application will help determine which manufacturing process is most cost-effective.

wire mesh price per square meter

4. Coatings and Treatments Additional treatments, such as powder coating, dip-coating, or galvanizing, can further increase the price per square meter. These coatings enhance the wire mesh's durability and resistance to environmental factors, making them suitable for various applications. For instance, coated wire mesh is often employed in landscaping and architectural features where aesthetics and longevity are crucial.

5. Quantity and Purchasing Agreements The quantity purchased can significantly impact the price. Bulk orders often receive discounts, reducing the overall cost per square meter. Establishing long-term purchasing agreements or working with suppliers who offer price breaks for recurring orders can result in substantial savings.

6. Market Demand and Trends Prices are also influenced by market demand, seasonal variations, and economic factors. For example, during construction booms or periods of high agricultural activity, demand for wire mesh can spike, leading to increased prices. Staying informed about market trends can aid buyers in timing their purchases to secure the best prices.

Conclusion

The price of wire mesh per square meter is determined by various elements, including material composition, mesh size, manufacturing processes, and market demand. By understanding these factors, consumers can make more informed choices that align with their specific needs and budgets. Whether you're in construction, agriculture, or another industry, being mindful of these aspects will enable you to select the appropriate wire mesh that meets both your application requirements and financial constraints. As with any material, conducting thorough research and comparing prices across different suppliers can yield the best results for your project.