In the bustling world of industrial manufacturing, the wire mesh industry stands out for its versatile applications and pivotal role in various sectors. At the heart of it all are the wire mesh manufacturers, entities that combine precision engineering, quality materials, and an in-depth understanding of industry demands to produce essential products. For any business venturing into construction, agriculture, or even artisanal crafts, understanding the nuances of selecting the right wire mesh manufacturer can be a game-changer.

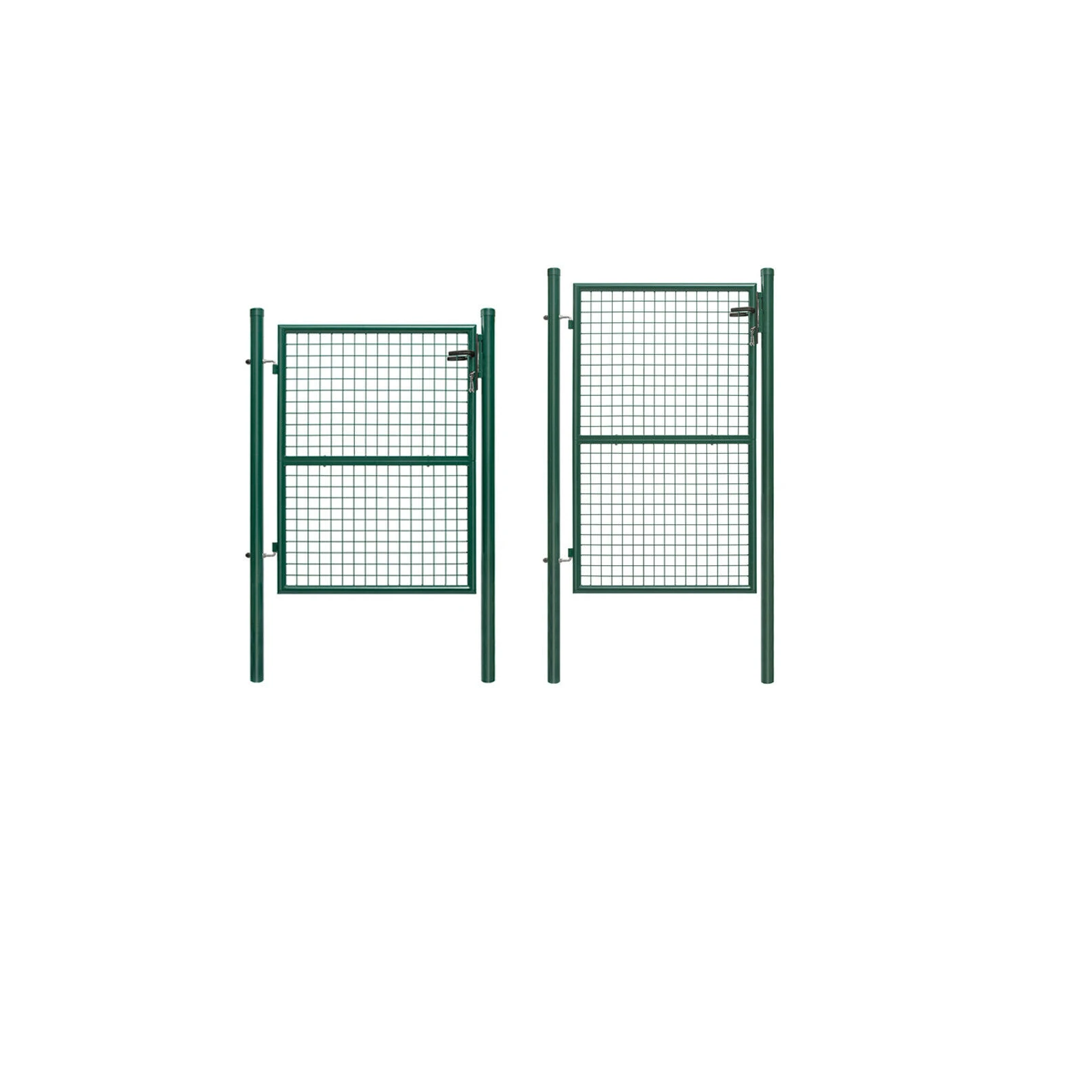

Wire mesh products are integral to numerous applications, ranging from security and fencing to filtration systems and architectural designs. A credible wire mesh manufacturer not only understands these diverse applications but also excels in producing customized solutions that meet specific needs. The expertise of a seasoned manufacturer lies in their ability to recommend the right material—be it stainless steel, carbon steel, or galvanized steel—based on the client's operational environment and longevity requirements.

Experience in the field dramatically influences the value a wire mesh manufacturer can provide. Manufacturers with decades of operation have undoubtedly encountered a myriad of industrial challenges and triumphs, optimizing their processes with each experience. This cumulative knowledge allows them to anticipate potential issues before they arise, ensuring stability and efficiency in their production lines. Clients benefit from this expertise through products that are meticulously designed and tested to meet stringent industry standards.

Authoritativeness in the wire mesh industry comes from a manufacturer’s commitment to continuous improvement and compliance with international standards. Reputable manufacturers often hold ISO certifications, demonstrating their adherence to globally recognized production and environmental practices. Their authoritative stance is further solidified through active participation in industry conferences, seminars, and by contributing to technical papers, where they share insights and advancements in wire mesh technology.

wire mesh manufacturers

Trustworthiness is perhaps the most critical attribute for any wire mesh manufacturer. Trust is built over time through transparent operations, consistent product quality, and a dedicated customer support system. Reliable manufacturers foster strong partnerships by maintaining open communication channels, offering comprehensive consultancy services, and ensuring post-sale support. This commitment to client relations not only enhances customer satisfaction but also promotes long-term business relationships.

The landscape of wire mesh applications is ever-evolving, with innovations in materials and manufacturing techniques continuously expanding its horizons. Forward-thinking manufacturers are at the forefront, integrating cutting-edge technologies like automation, advanced testing facilities, and AI-driven quality checks to exceed the conventional boundaries of wire mesh production. These innovations pave the way for products that offer superior strength, customizable configurations, and enhanced corrosion resistance.

Strategically, when businesses align with proficient wire mesh manufacturers, they gain more than just a product supplier—they partner with experts who contribute actively to their project’s success. Such partnerships encourage knowledge exchange, drive efficiency, and inspire sustainability in technical solutions, aligning with broader corporate and environmental goals.

In conclusion, as industries across the globe continue to advance, choosing the right wire mesh manufacturer becomes a pivotal decision. Evaluate potential manufacturers not only on the basis of their product offerings but also their experience, expertise, authoritativeness, and trustworthiness. By prioritizing these characteristics, businesses can secure a competitive edge through high-quality wire mesh solutions that reliably support their operations and innovate for future challenges.