The Wire Fence Factory An Intricate Web of Production and Innovation

In the world of manufacturing, wire products have carved out a significant niche, playing a vital role in various sectors, from agriculture to construction. Among the myriad of wire products, wire fences stand out for their versatility, durability, and effectiveness in protecting property, livestock, and gardens. A wire fence factory symbolizes not just the culmination of industrial efforts, but also the intricate process of creating essential products that enhance security and aesthetics.

At the heart of a wire fence factory lies a sophisticated production line, meticulously designed to produce high-quality wire fencing materials

. The process begins with the selection of raw materials, typically high-tensile steel or galvanized wire, which are known for their strength and resistance to rust and corrosion. These materials undergo rigorous quality checks to ensure that only the best are used in production. The factory environment is bustling with activity, as machines whirr and skilled workers oversee various stages of the manufacturing process.Once the raw materials are procured, the first step involves wire drawing, where large coils of steel are pulled through a series of dies to achieve the desired diameter. This step is crucial, as the thickness of the wire influences the fence's overall strength and resilience. After this, the wires are coated, often galvanized, to provide an additional layer of protection against environmental factors. The galvanization process involves immersing the drawn wire in molten zinc, creating a robust barrier against rust.

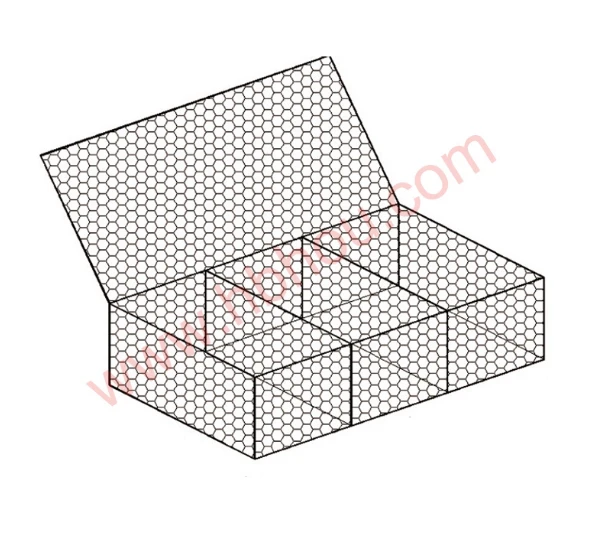

Following coating, the wires are shaped into various forms, depending on the specific design of the fence required. This stage includes processes such as weaving, welding, or even crimping to create different types of wire fencing, such as chain link, barbed wire, or welded wire panels. Each design serves unique purposes; for instance, barbed wire is commonly used in agricultural settings to deter animals, while chain link fencing is popular in residential and industrial applications for its transparency and security.

wire fence factory

Quality control is a cornerstone of operations in a wire fence factory. Each product undergoes thorough inspections to ensure compliance with industry standards. These checks assess not only the visual appearance of the fences but also their structural integrity. This diligence helps to build trust with customers who rely on the durability and safety of these products.

Innovation plays a crucial role in the wire fence factory's success. As trends and consumer preferences evolve, manufacturers are increasingly turning to advanced technology to improve efficiency and product quality. Automation in production processes and the use of computer-aided design (CAD) are revolutionizing the way wire fences are conceptualized and produced. Such technologies enable manufacturers to customize products quickly, accommodating specific needs and fostering customer satisfaction.

Furthermore, sustainability has become a significant focal point for modern wire fence factories. With an increased emphasis on eco-friendliness, many manufacturers are adopting practices such as using recycled materials and minimizing waste during production. These efforts not only contribute to environmental protection but also resonate with an environmentally conscious consumer base.

In conclusion, a wire fence factory is more than just a place where fences are made; it is a hub of innovation, quality control, and sustainability. From the selection of raw materials to the final inspection of finished products, every step in the production of wire fencing is carefully executed to ensure that customers receive reliable and durable solutions for their fencing needs. As the demand for practical and aesthetically pleasing fences continues to grow, wire fence factories are poised to play an increasingly important role in the manufacturing landscape, shaping the future of security and property enhancement.