The Essence of Wire Mesh Factory Crafting Versatile Solutions for Various Industries

Wire mesh factories play a crucial role in modern manufacturing, providing a myriad of products that serve various industries, from construction to agriculture. The core function of these factories is to produce wire mesh, a versatile material that consists of intersecting wires forming a gridlike pattern. This article delves into the operations of wire mesh factories, the significance of their products, and their impact on different sectors.

At the heart of every wire mesh factory is the production process, which involves several key steps. First, high-quality raw materials, usually in the form of coils of wire made from stainless steel, carbon steel, or other metals, are sourced. These materials are essential for ensuring the durability and strength of the finished wire mesh. Once the wires are obtained, they undergo a series of intricate processes, including cutting, weaving, and welding, to create the desired mesh.

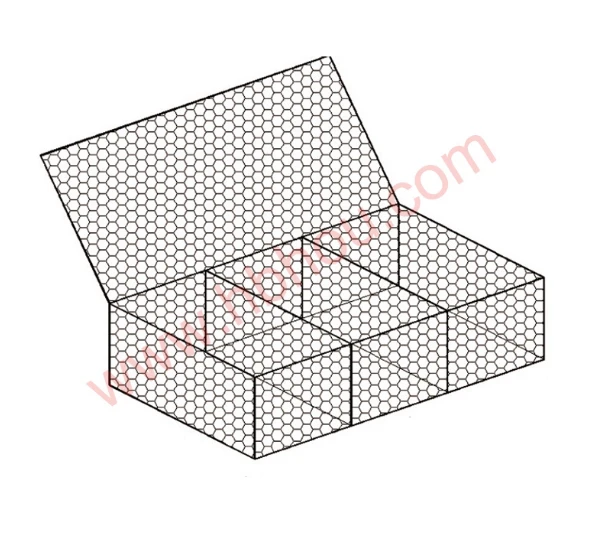

The weaving technique used in a wire mesh factory can vary significantly depending on the application of the product. The most common types of weaving include plain weave, twill weave, and Dutch weave. Each method influences the strength, flexibility, and applications of the final product. This diversity allows factories to cater to the specific needs of their clients, producing everything from fine mesh filters to heavy-duty architectural netting.

Wire mesh finds applications in numerous sectors, which amplifies the importance of wire mesh factories. In the construction industry, wire mesh is often employed as concrete reinforcement, enhancing structural integrity and reducing cracking. It is vital for creating durable sidewalks, highways, and various building components. The agricultural sector utilizes wire mesh for fencing and livestock enclosures, ensuring the safety and security of animals while allowing for proper ventilation and sunlight.

wire mesh factory

In addition, wire mesh factories contribute significantly to the manufacturing of industrial products. For instance, wire mesh is essential in the production of sieve filters and strainers, used in processing plants to separate solids from liquids. This function is indispensable in industries such as food production, pharmaceuticals, and chemical manufacturing, where purity and quality control are paramount.

Moreover, wire mesh products also find their way into decorative applications. Many designers and architects appreciate the aesthetic appeal of wire mesh, using it for facades, partitions, and art installations. This blend of functionality and design exemplifies the versatility of wire mesh as a material.

As industries continue to evolve, so too do the requirements for wire mesh products. With advancements in technology, wire mesh factories are adopting cutting-edge tools and techniques, such as automated weaving machines and innovative coating processes, to enhance the quality and durability of their products. Additionally, a growing focus on sustainability has led many manufacturers to explore eco-friendly materials and practices, ensuring that their operations align with environmental standards.

In conclusion, wire mesh factories are integral to a wide range of industries, providing essential products that enhance the effectiveness and efficiency of various applications. From construction to agriculture, the adaptability and strength of wire mesh underscore the significance of these factories in our daily lives. As technology progresses, the future looks promising for wire mesh production, paving the way for innovative solutions that meet the ever-evolving demands of the global marketplace.