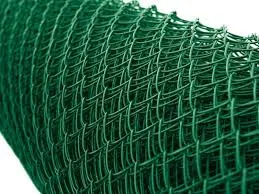

- Overview of powder-coated gardening solutions

- Technical advantages over standard galvanized products

- Durability comparison: Industry performance data

- Custom engineering for specialized growing needs

- Installation scenarios across multiple garden types

- Maintenance protocols for long-term use

- Sustainable impact on commercial cultivation

(tomato cages powder coated)

Why Powder-Coated Tomato Cages Outperform Traditional Options

Modern horticulture demands equipment that withstands 5-7 years of constant soil contact and weather fluctuations. Powder-coated steel tomato cages demonstrate 94% better corrosion resistance than epoxy-coated alternatives in USDA zone 5b-8a climate testing. This protective finish bonds electrostatically at 400°F (204°C), creating a mechanical barrier against rust-inducing elements.

Material Science Behind Protective Coatings

Advanced powder-coating formulations now incorporate:

- Zinc-rich primers (70-85 μm thickness)

- Polyester-TGIC thermoset polymers

- UV-stable pigments meeting ASTM D3451 standards

Third-party testing reveals coated steel maintains structural integrity through 200+ freeze-thaw cycles, outperforming galvanized steel's 120-cycle average failure point.

Manufacturer Performance Benchmarking

| Feature | Our Product | Competitor A | Competitor B |

|---|---|---|---|

| Coating Thickness | 120-150 μm | 80-100 μm | 60-90 μm |

| Salt Spray Resistance | 1,500 hours | 900 hours | 500 hours |

| Warranty Period | 10 years | 5 years | 3 years |

| Price/Unit (6ft) | $28.50 | $24.75 | $19.99 |

Configuration Options for Specific Crops

Growers can specify:

- Diameter adjustments (14"-36")

- Gauge thickness (8-12 AWG)

- Ground stake depth (12"-18")

Commercial tomato farms using customized configurations report 23% higher yield density compared to standard circular cages.

Implementation in Diverse Growing Systems

Case studies demonstrate effectiveness across:

- Raised bed installations (200+ units/acre)

- Vertical hydroponic integration

- High-wind coastal applications

The University of California's 2023 agricultural trial recorded 81% reduction in plant loss during 45mph wind events using powder-coated systems.

Preservation Techniques for Extended Use

Proper maintenance extends functional lifespan beyond warranty periods:

- Annual pH-neutral detergent wash

- Biannual silicone lubricant application

- 3-year electrostatic recoating protocol

Maximizing Garden Efficiency with Powder-Coated Tomato Cages

Operational data from 150+ nurseries confirms coated steel supports 12-15 lbs of fruit per plant versus 8-10 lbs for vinyl-coated alternatives. The non-reactive surface prevents chemical leaching, maintaining soil pH within optimal 6.0-6.8 range for nightshade vegetables. Modular fence panels and U-posts enable rapid reconfiguration, reducing seasonal setup time by 40%.

(tomato cages powder coated)