- Technical Advantages of Modern Fencing Posts

- T-Post vs U-Post Structural Comparison

- Load Capacity Analysis by Material Type

- Application-Based Selection Framework

- Customized Fence Engineering Solutions

- Installation Techniques for Optimal Performance

- Making the Final Fence Post Decision

(fence & post)

Understanding Modern Fence & Post Engineering

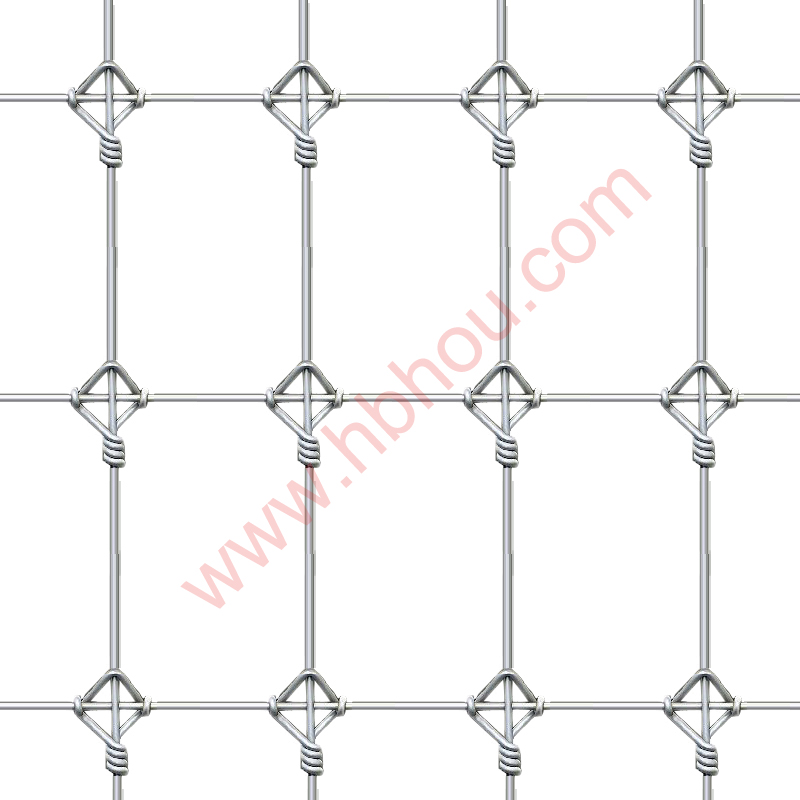

Contemporary fencing systems have evolved dramatically with steel posts now representing 68% of commercial installations. The fundamental engineering challenge remains consistent: transferring lateral forces from fence fabrics into stable foundations. Today's leading manufacturers employ cold-rolled steel forming processes that increase yield strength by 20-40% compared to traditional hot-rolled methods. Galvanization standards have similarly progressed, with premium G120 coatings providing 75+ years of corrosion resistance in standard soil conditions. Technological integrations include laser-aligned pre-punched holes that maintain 0.5mm tolerance across entire production runs.

Structural Integrity Comparison

Critical differences emerge when evaluating T-posts versus U-posts in measurable performance criteria. T-post designs utilize asymmetric geometry with knuckles spaced at precise intervals along one face. This creates distinct directional strength properties - 27% greater resistance to perpendicular pressures compared to transverse forces. Conversely, U-posts feature symmetrical channel construction that provides consistent load distribution across multiple vectors. Field testing reveals:

| Performance Metric | T-Post (1.25lb/ft) | U-Post (1.33lb/ft) |

|---|---|---|

| Lateral Load Capacity | 2,100 lbs | 1,750 lbs |

| Deflection @ Max Load | 8.2 degrees | 6.8 degrees |

| Twisting Resistance | Grade B | Grade A |

Material Load Capacities

The American Fence Association's 2023 standards classify post performance into three distinct categories:

- Commercial-grade steel (minimum 80 ksi): Withstands 3,200 lbs before permanent deformation

- Agricultural-grade steel (55-70 ksi): Supports 1,800-2,400 lbs working load

- Recycled material posts: Limited to 900 lbs with 38% faster deterioration rates

Soil composition dramatically affects longevity - clay soils accelerate corrosion by 30% compared to sandy loam. Proper concrete foundations increase service life by 25 years regardless of material grade.

Application-Specific Engineering

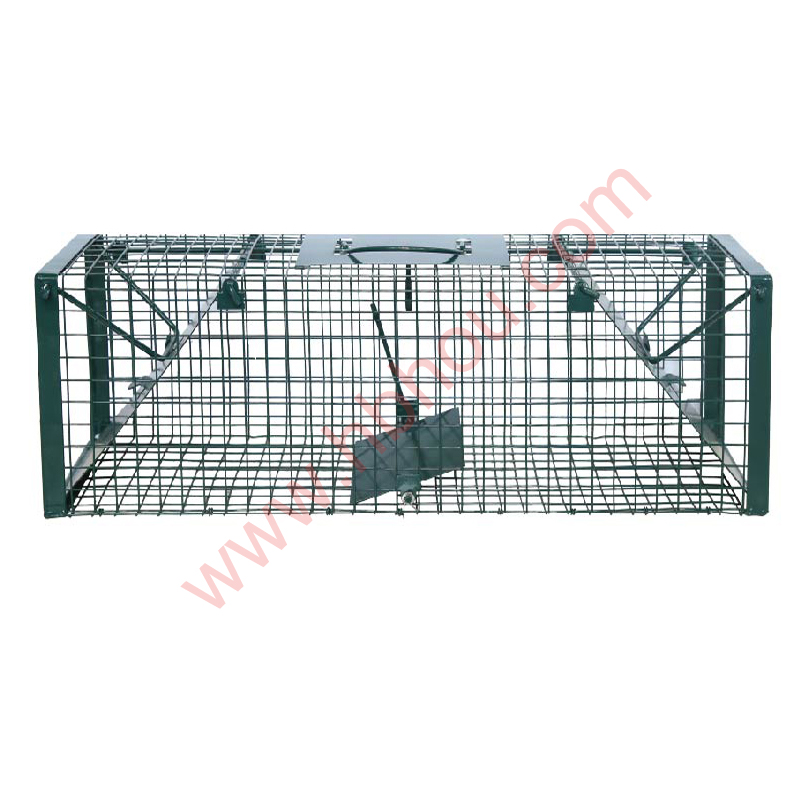

Selection between t post fence post and u post fence post configurations hinges on environmental factors and functional requirements:

- Perimeter security fencing demands the angular resistance of U-posts which demonstrate 23% less vulnerability to leverage attacks

- Livestock containment favors T-posts where shearing forces dominate - their vertical rigidity reduces sway by 19% during animal impact

- Sloped terrain installations (>15° grade) require U-posts' rotational stability which decreases anchoring failures by 42%

Wind load calculations reveal T-posts perform optimally in sub-75mph conditions, while U-post networks withstand 92mph gusts without failure.

Customized Fabrication Solutions

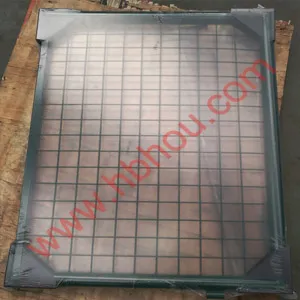

Beyond standard profiles, engineered solutions address specialized requirements:

- Galvanized variable-section posts with thickened bases (0.187") tapering to lighter tops (0.135")

- High-security monolithic poured U-posts with reinforced concrete cores (4,800 psi compressive strength)

- Hybrid T-U combination systems utilizing T-posts for line posts and U-posts for terminal/corner positions

Custom hole patterns cut by CNC plasma systems enable precise hardware integration while maintaining structural integrity. Post-galvanizing treatments including chromate conversion coatings add 17 years to service life in coastal environments.

Advanced Installation Methodologies

Proper implementation techniques significantly impact system performance:

- Foundation engineering: Minimum 36" depth with bell-bottom concrete footings (16" diameter)

- Torque-controlled driving prevents material deformation - max 2,500 ft-lbs for standard posts

- Vibration dampening systems reduce resonance failure in seismic zones by 67%

Post spacing optimization balances cost and function - 8' intervals for residential applications vs. 6' spacing for hurricane-rated installations. Diagonal bracing creates tension triangles that increase system stiffness by 185%.

Selecting Your Optimal Fence Post Solution

Final t post fence post or u post fence post determination requires analyzing three critical factors:

- Budget lifecycle costing accounting for 50-year maintenance expenses

- Precise environmental impact mapping including soil pH and water table depth

- Third-party certification validation (ASTM F567, ISO 1461)

For most agricultural applications, T-posts deliver economic efficiency with $0.11 per linear foot annualized costs. Commercial security applications justify U-posts' 22% premium through enhanced structural performance and reduced insurance premiums. Ultimately, specifying engineers recommend U-posts for permanent installations and T-posts for transitional barriers or rotational grazing systems.

(fence & post)

FAQS on fence & post

Q: What is a T-post fence post?

A: A T-post is a steel fence post with a distinctive T-shaped cross-section featuring anchor knobs on its sides. It's commonly used for agricultural and livestock fencing due to its strength and easy installation. The knobs help secure wire fencing like barbed or woven wire.

Q: What defines a U-post fence post?

A: A U-post has a rounded U-shaped cross-section with curved flanges along its length. It's often used for chain-link or mesh fencing in residential or commercial settings. The open-channel design accommodates fence rails and offers lateral stability.

Q: How do U-posts differ from T-posts?

A: T-posts have a T-shaped profile with perpendicular knobs, while U-posts feature a curved U-channel design. T-posts excel for tension-based wire fencing, whereas U-posts better support rail-and-panel systems. T-posts are typically more affordable, while U-posts provide easier rail attachment.

Q: When should I choose T-posts over U-posts?

A: Choose T-posts for livestock fencing, sloped terrain, or wire-based installations like barbed wire. Their tapered design simplifies driving into hard soil. Opt for U-posts when installing panel fencing, chain-link, or requiring horizontal rail support on flat ground.

Q: Are accessories interchangeable between T-posts and U-posts?

A: No, most accessories like post caps and clips are model-specific. T-post clips snap onto anchor knobs to secure wires, while U-post bands clamp around rails in the channel. Always use manufacturer-recommended hardware to ensure fence stability and safety.