Understanding Stainless Steel Wire Cloth Mesh A Versatile Material

Stainless steel wire cloth mesh is an incredibly versatile material that has found applications in a wide array of industries, from construction and automotive to food processing and pharmaceuticals. Comprised of interwoven strands of stainless steel, this mesh offers strength, durability, and resistance to corrosion, making it an ideal choice for various environments and uses.

Composition and Types

Stainless steel wire cloth mesh is primarily made from stainless steel grades such as 304, 316, or 430. The choice of grade usually depends on the specific requirements of the application, including factors such as corrosion resistance, strength, and temperature tolerance. For example, 316 stainless steel is often preferred for marine applications because of its superior resistance to saltwater corrosion, while 304 stainless steel is commonly used in food processing due to its non-reactive properties.

There are numerous types of wire cloth mesh based on weave patterns, which can include plain weave, twill weave, and Dutch weave, among others. These different weaves affect the mesh's characteristics, such as its filtration capabilities and mechanical strength. Plain weave is the most common type, offering good balance between strength and flexibility, while twill weave provides increased surface area and better filtration performance.

Applications

The applications of stainless steel wire cloth mesh are incredibly diverse. In the construction industry, it is employed for reinforcing concrete, as a barrier for fences, and as window screens. In the automotive sector, it is used in filters, exhaust systems, and heat exchangers due to its ability to withstand high temperatures and resist chemical reactions.

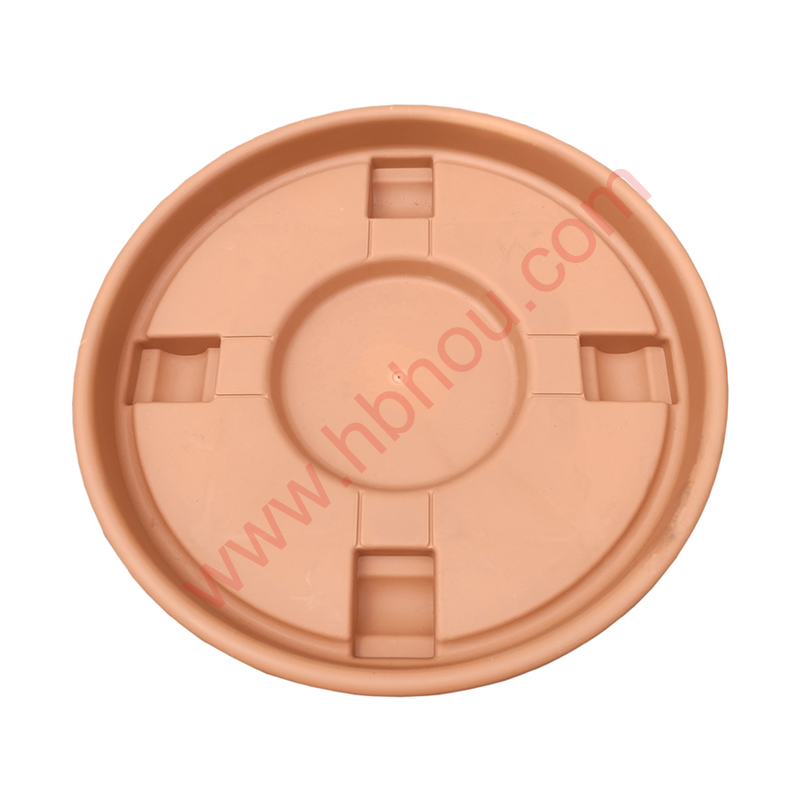

stainless steel wire cloth mesh

In the food and beverage industry, hygiene and safety are paramount. Stainless steel wire cloth mesh is used in the manufacturing of equipment such as brewing tanks, food processing machinery, and strainers. Its smooth surface is easy to clean, making it suitable for environments that require strict sanitary standards.

Moreover, in the pharmaceutical sector, the accuracy of filtration is essential. Stainless steel wire mesh is used in filtration systems that ensure the purity of medications and other consumables. The durability of stainless steel ensures that the mesh retains its integrity under rigorous cleaning and sterilization processes.

Advantages

The advantages of using stainless steel wire cloth mesh are numerous. One of the most significant benefits is its durability. Unlike other materials, stainless steel resists rust and corrosion, prolonging its lifespan and reducing the need for frequent replacements. This makes it a cost-effective choice for long-term projects.

Another advantage is its strength-to-weight ratio. Stainless steel wire cloth mesh is lightweight yet incredibly strong, allowing it to be used in applications where weight is a concern without sacrificing structural integrity. Furthermore, stainless steel mesh is highly versatile; it can be manufactured in various specifications – including different wire diameters, mesh sizes, and roll lengths – to meet specific project requirements.

Conclusion

In conclusion, stainless steel wire cloth mesh is a remarkable material that plays a crucial role in various industries. Its combination of strength, durability, and resistance to corrosion makes it a preferred choice for applications where reliability is critical. Whether it’s for enhancing safety in a construction project, ensuring hygiene in food processing, or facilitating precision in pharmaceuticals, the benefits of stainless steel wire cloth mesh are undeniable. As industries continue to evolve and demand for high-quality materials grows, stainless steel wire cloth mesh is likely to remain a staple resource, adapting to new challenges and opportunities. Its versatility ensures that it will continue to serve a wide range of functions across numerous applications, solidifying its place as a vital component in modern manufacturing and production.