Stainless Steel Wire Mesh is a key solution in the manufacturing industry, specifically within Fabricated metal products and Manufacturing of metal wire ropes and their products. This article explores how Hebei Houtuo Co., Ltd supports professionals with durable, high-performance products, and explains why this product is an ideal choice for businesses in these sectors.

Table of Contents

- Stainless Steel Wire Mesh Overview

- Benefits & Use Cases of Stainless Steel Wire Mesh in Manufacturing of metal wire ropes and their products

- Cost, Maintenance & User Experience

- Sustainability & Market Trends in manufacturing

- Conclusion on Stainless Steel Wire Mesh from Hebei Houtuo Co., Ltd

Stainless Steel Wire Mesh Overview

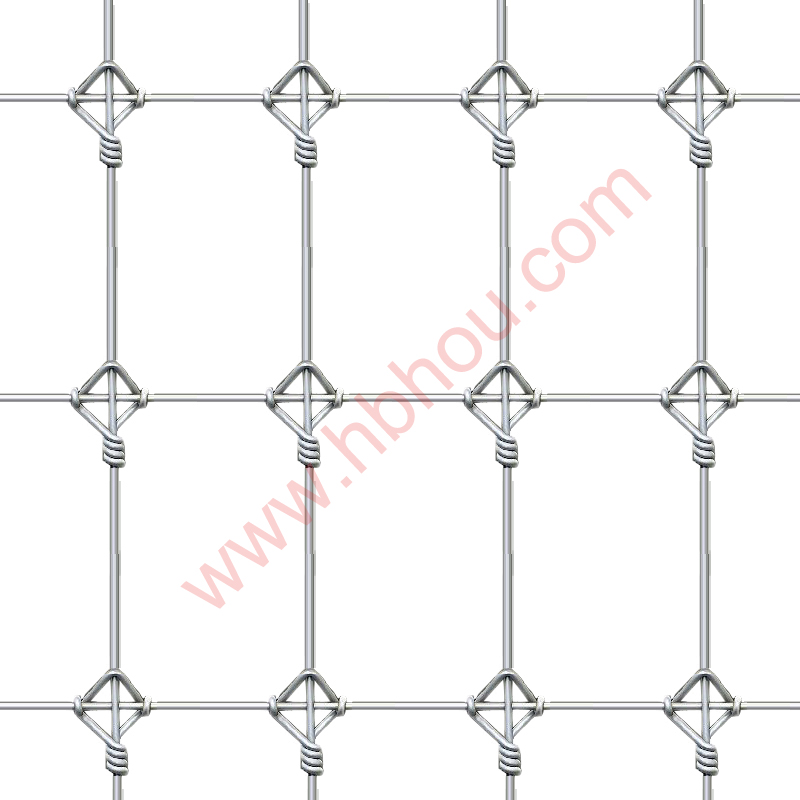

For B2B manufacturers, Stainless Steel Wire Mesh is a fundamental material for screening, guarding, conveying, and filtration. Available as stainless steel woven wire mesh, stainless steel welded wire mesh, stainless steel wire mesh panels, and stainless steel wire rope mesh, it delivers stable aperture control, strength-to-weight advantages, and long-term corrosion resistance. Hebei Houtuo Co., Ltd engineers mesh using common grades such as 304/304L and 316/316L, with options in 310S and duplex (2205) for higher temperature or chloride-rich environments. Typical woven wire specifications range from 2–500 mesh counts with wire diameters from 0.02–5.0 mm and weaves including plain, twill, and Dutch weaves for precise filtration. Welded configurations feature apertures commonly from 6–50 mm, with panel sizes up to 1500 × 3000 mm and tight tolerances aligned with ISO 9044 and ASTM E2016 for industrial wire cloth.

Houtuo’s vertically integrated production—covering wire drawing, weaving/resistance welding, cutting, framing, and surface finishing (pickling/passivation per ASTM A967 and optional electropolishing)—ensures repeatable quality and fast lead times. A recent deployment for a cable-stranding line replaced carbon steel guards with 316 welded panels, improving visibility and eliminating rust-related maintenance; inspection time dropped while safety compliance improved. With material traceability (MTC 3.1 on request) and optical aperture verification, Houtuo provides dependable mesh tailored for demanding shop-floor conditions.

Benefits & Use Cases of Stainless Steel Wire Mesh in Manufacturing of metal wire ropes and their products

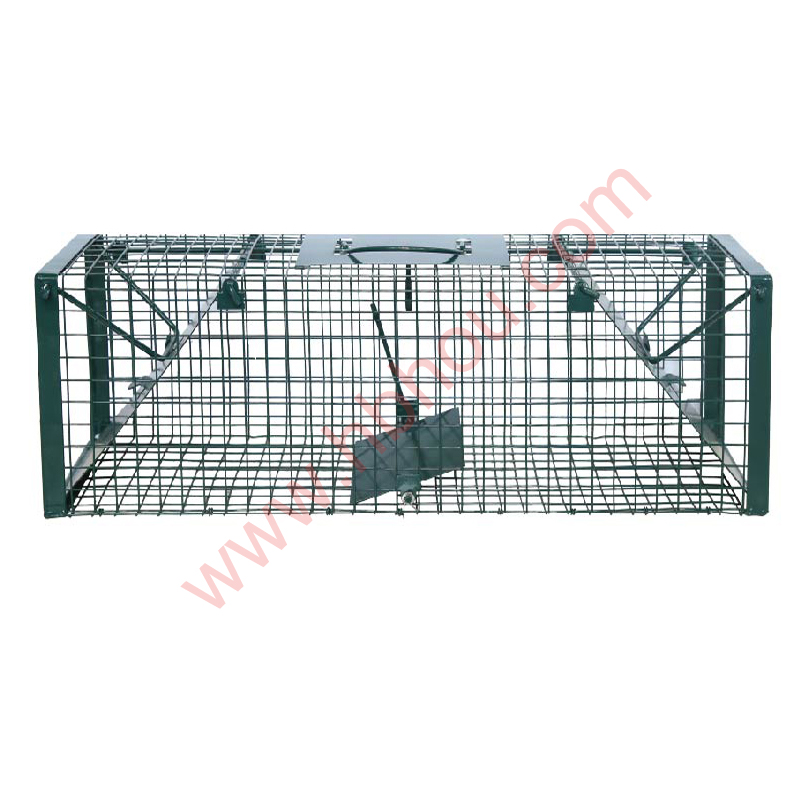

In wire rope manufacturing, mesh supports multiple production stages and EHS requirements. Stainless steel welded wire mesh guards help machine builders and plant engineers meet ISO 14120/OSHA safeguarding standards on stranding, closing, and cabling lines, while allowing clear sightlines for operators. Woven meshes serve as filtration screens for drawing lubricants and process oils, as well as for shot media classification in blasting and peening. Heat-resistant woven belts and trays facilitate annealing and washing. Finished-goods logistics benefit from robust stainless steel wire mesh panels for racks, cages, and pallets that resist deformation and corrosion. For architectural and safety applications around production facilities and showrooms, stainless steel wire rope mesh provides high-strength, lightweight infill that is both secure and visually refined.

Competitive advantages include excellent corrosion and abrasion resistance, high tensile stability, temperature tolerance, easy cleaning, and lifecycle economy versus carbon steel or galvanized alternatives. Hebei Houtuo Co., Ltd offers CNC-cut, edge-hemmed, or TIG-framed panels; custom aperture/wire diameter pairings; and anti-snag finishing to protect cables and operators. With CAD-to-fabrication support and rigorous QA (aperture flatness, weld shear strength, and dimensional checks), Houtuo streamlines OEM integration and MRO replacements, reducing downtime and simplifying inventory standardization across lines and sites.

Cost, Maintenance & User Experience

While the initial purchase price of stainless mesh can exceed carbon steel by 20–40%, total cost of ownership typically favors stainless due to 3–5× longer service life, reduced repainting/coating, and fewer corrosion-related stoppages. Plants report lower spare consumption and less unplanned downtime for guard repairs and filter changeouts—key drivers for ROI often realized within 12–18 months. Hygienic passivated surfaces clean quickly, supporting 5S and ISO-based maintenance systems while maintaining machine visibility and operator safety.

Feedback from fabricated metal product managers highlights consistent flatness and aperture uniformity in Houtuo’s stainless steel woven wire mesh, as well as robust weld integrity in stainless steel welded wire mesh panels. The company’s packaging standards minimize handling damage and edge deformation, enabling plug-and-play installation. Users appreciate rapid repeat-order fulfillment, clear material traceability, and dedicated engineering support for custom framed panels that match existing mounts and safety interlocks—shortening changeover times and simplifying audits.

Sustainability & Market Trends in manufacturing

Stainless steel’s recyclability (commonly 80–90% scrap content in the supply chain) and long service life make it a strong fit for decarbonization goals and ESG reporting. As regulatory frameworks expand—covering REACH/RoHS, waste minimization, and circularity—manufacturers are selecting materials that reduce repainting, solvent use, and replacement frequency. Safety standards are also accelerating the shift to engineered guarding solutions, with stainless outperforming painted mild steel in harsh, lubricant-rich or coastal environments. In parallel, demand is rising for stainless steel wire rope mesh in architectural safety systems that combine load-bearing strength with open-area aesthetics.

Hebei Houtuo Co., Ltd aligns operations with ISO-based quality and environmental management practices, pursuing energy-efficient weaving and welding equipment, closed-loop rinse water management, and recyclable packaging. On request, Houtuo provides material declarations (REACH/RoHS) and MTC 3.1 documentation to support compliance audits. Forward-looking investments in precision metrology and digital traceability help customers de-risk supply chains, while design-for-durability principles cut lifecycle emissions and TCO without compromising throughput or safety.

Conclusion on Stainless Steel Wire Mesh from Hebei Houtuo Co., Ltd

From filtration screens and conveyor belts to machine guarding and architectural infill, Stainless Steel Wire Mesh delivers performance, safety, and lifecycle value across the fabricated metal products sector and the manufacturing of metal wire ropes and their products. Hebei Houtuo Co., Ltd combines materials expertise, precise fabrication, and responsive service to supply stainless steel woven wire mesh, stainless steel welded wire mesh, stainless steel wire mesh panels, and stainless steel wire rope mesh built for demanding environments. Contact us: email: denny@hbhou.com. Visit our website: https://www.hbhou.com