Understanding Square Woven Wire Mesh Versatility and Applications

Square woven wire mesh is an essential material widely utilized across various industries due to its strength, versatility, and aesthetic appeal. Constructed from high-quality wires woven together in a square pattern, this type of mesh offers flexibility in applications ranging from industrial to decorative uses.

Composition and Manufacturing Process

Square woven wire mesh is typically made from steel, stainless steel, galvanized iron, or other metal alloys, which provide durability and resistance to corrosion. The manufacturing process involves precision weaving techniques that ensure uniformity in the mesh opening sizes, spacing, and wire diameter. This consistency allows for a strong product that meets the specific requirements of different applications.

The wires can vary in thickness, allowing for customization based on the strength and weight capacity required. The most common mesh openings range from fine to coarse, catering to diverse filtering, screening, or fencing needs. The surface finish can also be customized; for example, some meshes come with a powder coating or are electroplated to enhance corrosion resistance and aesthetic appeal.

Key Characteristics

One of the standout features of square woven wire mesh is its excellent tensile strength, making it suitable for environments that require structural stability. Additionally, its square openings provide uniformity, ensuring even distribution of weight and load. The open pattern facilitates air and light passage while providing a barrier, making it ideal for applications where visibility is essential without compromising safety.

Another notable characteristic is the ease of installation. Square woven wire mesh can be easily cut, bent, and formed into various configurations, which makes it convenient for custom projects. It is lightweight, which simplifies transportation and setup, especially for large installations.

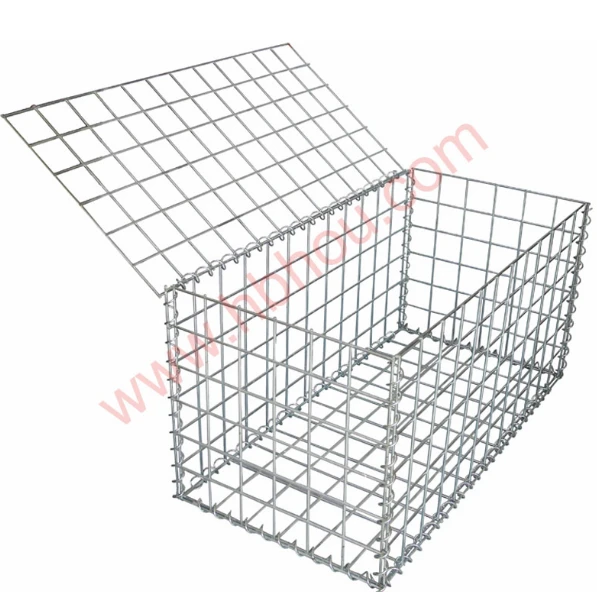

square woven wire mesh

Applications Across Industries

Square woven wire mesh finds its applications across a multitude of industries. In construction, it is often used for reinforcing concrete, providing additional strength to structures while allowing for greater design flexibility. The architectural industry also utilizes this mesh for ventilation in both commercial and residential buildings, as it offers a modern aesthetic while maintaining airflow.

In agriculture, square woven wire mesh is vital for fencing livestock and protecting crops from unwanted animals. Its sturdy construction ensures that the mesh remains intact amid harsh environmental conditions. Moreover, in the manufacturing sector, it serves as a reliable option for filtering and separating materials in processes like mining and recycling.

The automotive and aerospace industries also leverage the properties of square woven wire mesh for screening applications, ensuring that only the desired elements pass through while blocking debris or contaminants.

Conclusion

The versatility of square woven wire mesh makes it a crucial component in various applications across different sectors. Its strength, combined with customizable features such as wire thickness and surface finish, allows industries to meet specific requirements effectively. As industries continue to innovate, the demand for square woven wire mesh is likely to grow, further cementing its role as an indispensable material in modern manufacturing and construction processes.

In summary, whether for functional purposes or aesthetic enhancements, square woven wire mesh provides a valuable solution that meets the ever-evolving needs of various industries, showcasing its importance in both everyday applications and specialized innovations.