Understanding Silt Fencing A Comprehensive Overview

Silt fencing is an essential tool in the realm of environmental protection and construction management. It serves as a sediment control measure that prevents soil erosion and minimizes the migration of silt and other particles into nearby water bodies. This article focuses on the specifics of silt fencing, especially the dimensions often represented as “3 x 100,” which typically refer to a silt fence that is 3 feet high and 100 feet long.

What is Silt Fencing?

Silt fencing is made of synthetic fabric, typically geotextile material, which is designed to filter out sediments while allowing water to pass through. The fabric is installed vertically, supported by wooden or metal stakes, creating a barrier that channels water runoff and traps sediment. The installation of silt fences is particularly crucial during construction projects, land development, and agricultural activities where soil disturbance is prevalent.

Importance of Silt Fencing

The significance of silt fencing cannot be understated, especially in protecting natural water resources. Soil erosion not only depletes fertile land but also leads to increased sedimentation in rivers, lakes, and streams. This sedimentation can harm aquatic ecosystems, disrupt water quality, and lead to costly clean-up operations. By effectively using silt fencing, project managers can help mitigate these environmental impacts.

Dimensions Explained 3 x 100

The designation “3 x 100” refers to the physical size of the silt fence. A 3-foot high silt fence means that the fabric stands 3 feet above the ground level, which is generally adequate to control sediment runoff in most areas. The 100-foot length allows for extensive coverage across a job site or specific area prone to erosion.

When selecting the right size for a silt fence, it is vital to consider the terrain, the slope of the land, and the expected volume of runoff. In some cases, additional height may be required, and multiple sections may be needed to cover larger areas effectively.

Installation Process

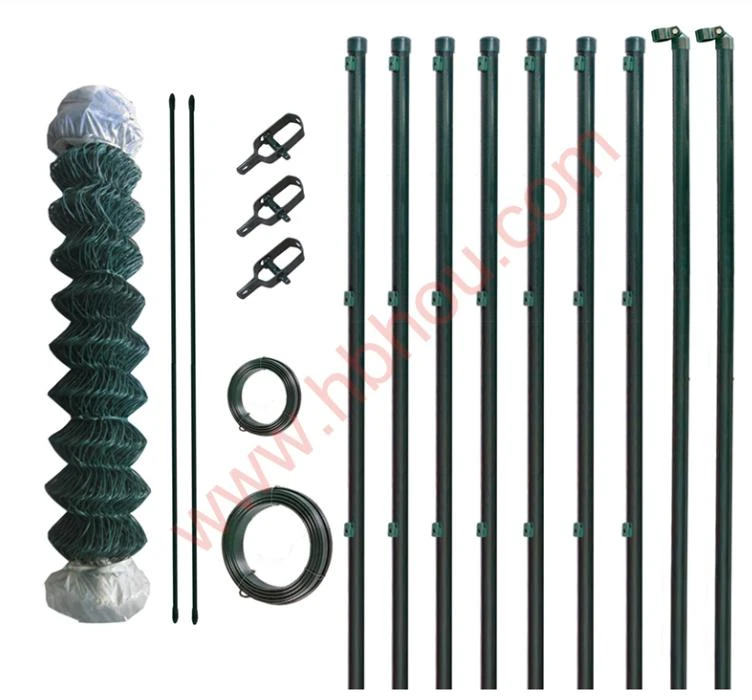

silt fencing 3 x 100

Installing silt fencing requires careful planning and execution. Here’s a step-by-step guide to effectively setting up a 3 x 100 silt fence

1. Site Assessment Before installation, evaluate the area for potential erosion points and water flow patterns. Determine where the fence will be most effective.

2. Prepare the Ground Clear the installation area of any debris, vegetation, or obstacles to ensure a smooth setup.

3. Stake Placement Drive stakes into the ground at regular intervals (usually 6 to 8 feet apart) along the perimeter where the silt fence will be installed. Ensure they are adequately secured into the ground for stability.

4. Attach Fabric Unroll the silt fence fabric and attach it to the stakes. The bottom edge of the fabric should be buried underground to prevent sediment from passing underneath.

5. Create a Trench Dig a small trench at the base of the fence (about 6 inches deep) before burying the fabric edge. This further enhances the fence's ability to trap sediments effectively.

6. Monitoring and Maintenance Regularly inspect the silt fence for any signs of damage or breaches. After heavy rainfall events, check for sediment accumulation and clean or replace the fabric as necessary.

Conclusion

Silt fencing is a vital component in managing soil erosion and protecting water quality. The “3 x 100” specification represents a commonly used size for effective sediment control. While its installation may seem straightforward, careful attention should be paid to site assessment, proper installation techniques, and ongoing maintenance. By implementing silt fencing appropriately, contractors and landowners can contribute significantly to environmental sustainability and compliance with erosion control regulations. Ultimately, investing time and resources into effective sediment management practices such as silt fencing can pay dividends in protecting our natural landscapes and water sources for generations to come.