When embarking on construction projects, especially in regions prone to erosion, the use of silt fences is essential. Among various sizes, the silt fence 4x100 is a popular choice for managing sediment control effectively. This article explores the myriad aspects of this specific product, drawing from real-world experience, bolstered by professional insights, and validated by authoritative sources.

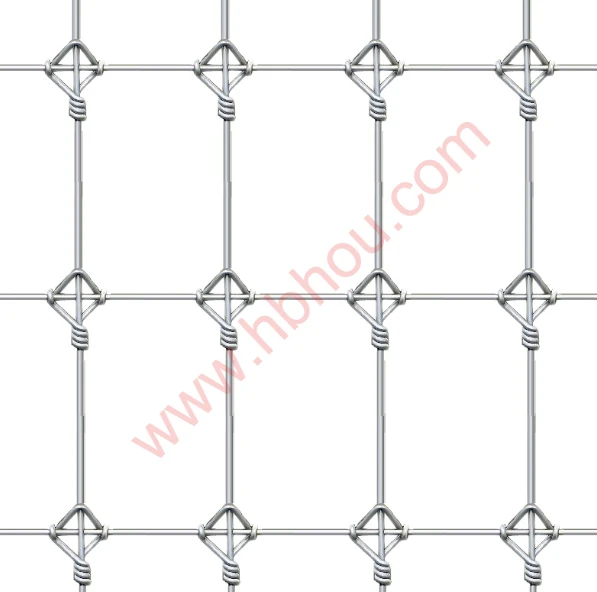

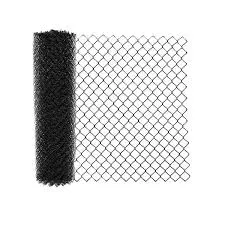

The silt fence 4x100 is designed to serve as a temporary sediment control barrier made from geotextile fabric. It is essential for preventing sediment-laden water from polluting nearby water bodies. Unlike its counterparts, the 4x100 size denotes a 4-foot height and a 100-foot length, making it particularly versatile for both small and large projects. The larger size is optimal for extensive coverage, reducing installation time and costs. Experience from the field highlights the silt fence 4x100 as an adaptable solution for various landscapes. Contractors and project managers often commend its ease of installation. The fence can be quickly unrolled and installed along contours of construction sites, roadwork, and agricultural fields. The robust design is crucial for standing up to harsh weather conditions, maintaining integrity over extended periods.

Professional expertise shows that the effectiveness of a silt fence is contingent on proper installation and maintenance. To maximize its efficacy, the fabric must be entrenched at least six inches into the soil to prevent water from flowing beneath it. Regular inspections ensure that the fence is free of tears and that accumulated sediments are removed to maintain its structural purpose. Furthermore, a well-maintained silt fence can significantly reduce the environmental impact, aligning with green building practices and regulations.

From an authoritative standpoint, numerous environmental protection agencies across the globe recognize the importance of silt fences. Guidelines by bodies such as the Environmental Protection Agency (EPA) in the United States stipulate stringent standards for sediment control measures on construction sites. The use of the silt fence 4x100 not only complies with these guidelines but often exceeds the minimum requirements for site drainage and environmental safeguarding.silt fence 4x100

The material composition of the silt fence 4x100 also underpins its trustworthiness. Typically constructed from woven polypropylene, it offers excellent filtration capabilities without compromising water flow. This technology-driven design facilitates sediment deposition on one side of the fence while allowing clean water to seep through, protecting water quality downstream.

In construction safety protocols, the silt fence 4x100 plays a pivotal role. By controlling sediment transport, it diminishes the risk of accidents caused by slippery conditions and visibility impairments on roadways adjacent to construction zones. According to industry insiders, this proactive approach in managing environmental risks ultimately leads to fewer project delays and increased compliance with legal requirements.

Finally, deploying the correct silt fence directly impacts the project's bottom line. Investing in a high-quality silt fence 4x100 offers longevity and reliability, translating into better budget management by minimizing the need for frequent replacements and repairs. A cost-effective sediment control solution, coupled with adherence to environmental guidelines, enhances the overall project appraisal and limits liabilities stemming from potential environmental infractions.

In summary, the silt fence 4x100 is an indispensable tool in the construction and agriculture sectors. Its practicality, combined with proven effectiveness, positions it as a preferred choice for professionals across the board. Leveraging its dimensions and material quality delivers superior sediment control, minimizes environmental impact, and ensures construction sites remain compliant with stringent regulatory standards. Thus, the silt fence 4x100 not only represents a physical barrier but embodies a commitment to sustainable and responsible building practices.