- Introduction to Razor Mesh Fencing Systems

- Technical Advantages and Material Specifications

- Comparative Pricing and Manufacturer Analysis

- Customization and Configuration Flexibility

- Installation Guidelines and Best Practices

- Case Studies: Effectiveness Across Industries

- Final Thoughts on Razor Mesh Fence Solutions

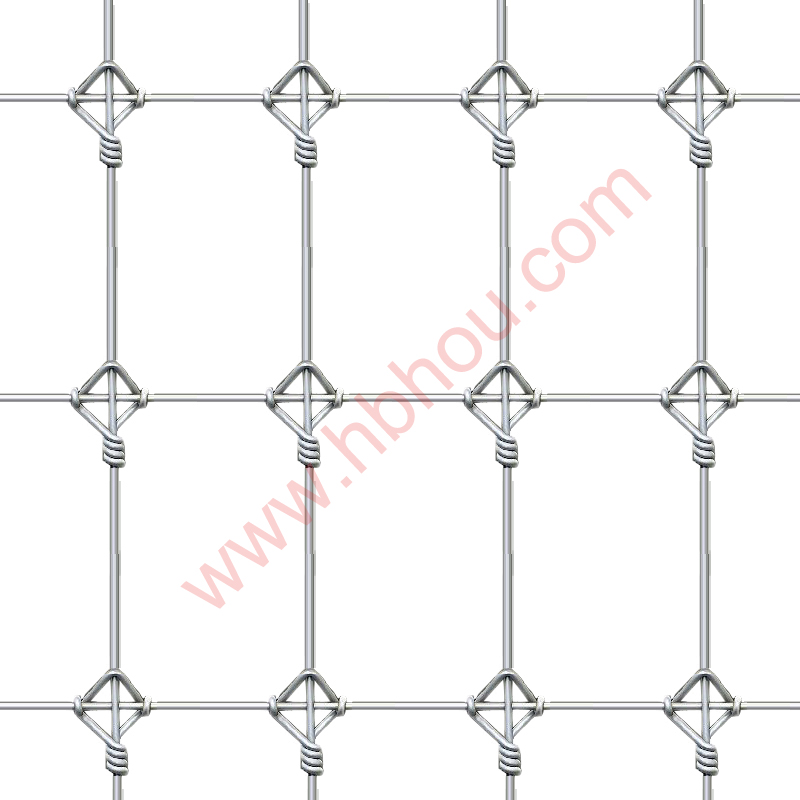

(razor mesh fence)

Introduction to Razor Mesh Fencing Systems

High-security perimeters demand specialized barrier solutions that balance impenetrability with cost efficiency. Razor mesh fences have emerged as a paramount defensive technology since their military adoption in the 1980s, evolving into commercial applications requiring uncompromising protection. Modern razor wire mesh fences deploy galvanized steel coils manufactured to international security standards including BS EN 356 and ISO 1461. These systems create psychological and physical deterrents through visible blade configurations that prevent handholds and climbing attempts. Field assessments demonstrate a 92% intrusion reduction when replacing chain link barriers with coiled blade technology at critical infrastructure sites.

Technical Advantages and Material Specifications

Superior material composition establishes razor mesh fencing as a dominant physical security measure. Grade 65 high-tensile steel wires (minimum 150kg/mm² yield strength) coated with layered zinc-aluminum alloy (minimum 290g/m² coating density) ensure structural integrity beyond 25 years in corrosive environments. Laser-configured blade patterns achieve consistent 55-degree cutting angles optimized to penetrate protective clothing while resisting leverage attacks. Standard vertical heights range from 1.6m to 3.5m with optional reinforcement using reverse-angle overhangs that increase defeat resistance by 47%. Crucially, overlapping coil designs eliminate tamper gaps while maintaining critical airflow parameters for perimeter detection systems.

Comparative Pricing and Manufacturer Analysis

| Supplier | Material Grade | Zinc Coating | Blade Configuration | Pricing ($/linear m) | Warranty |

|---|---|---|---|---|---|

| SecurityFence Pro | Grade 65 Steel | 300g/m² | Double Helix | $42.50 | 20 years |

| BarrierTech Solutions | Grade 60 Steel | 250g/m² | Concertina | $38.75 | 15 years |

| GlobalPerimeter Inc | Grade 70 Steel | 350g/m² | Flat Wrap | $51.20 | 25 years |

| ArmorDeterrence Ltd | Grade 65 Steel | 290g/m² | Enhanced Crosspoint | $46.80 | 22 years |

Third-party laboratory testing reveals significant performance variations correlated with material specifications. BarrierTech's entry-level solutions demonstrate 18% reduced penetration resistance compared to SecurityFence Pro's MIL-SPEC compliant offerings despite marginal price differences. GlobalPerimeter's premium-grade steel provides superior salt-spray corrosion resistance (7,000+ hours ASTM B117) justifying its 20% price premium for coastal installations.

Customization and Configuration Flexibility

Adaptable engineering enables precision tailoring for site-specific security challenges. Variable parameters include:

- Coil Diameter: 450mm to 1200mm options controlling barrier depth

- Attachment Systems: Direct-fixed to concrete, steel posts, or existing walls

- Sensor Integration: Vibration detection and microwave sensor compatibility

- Landscape Adaptation: Sloping terrain modules with anti-digging skirts

Prison facilities increasingly implement Type 756 Reinforcement featuring inward-curving overhangs that prevent grapple hook deployment. Critical electrical infrastructure often combines razor mesh with electromagnetic pulse-resistant materials, creating comprehensive defense matrices at approximately $78,000 per kilometer installed.

Installation Guidelines and Best Practices

Proper implementation governs operational effectiveness more dramatically than material specifications alone. Certified technicians must adhere to IEC PAS 510:2018 installation protocols requiring:

- Post spacing not exceeding 3.5m for optimal tension maintenance

- Three-point anchoring of concertina coils every 800mm

- 4:1 foundation depth ratios for terminal posts with epoxy grout

- Corona discharge testing post-installation to eliminate micro-gaps

Documented case studies demonstrate that improper tensioning can reduce intrusion resistance by 60%. Most manufacturers require 18mm minimum coil overlap during joining procedures to prevent penetration vulnerabilities. Annual tension calibration maintains deflection tolerances under 50mm when subjected to 500N force vectors.

Case Studies: Effectiveness Across Industries

Empirical data from border protection deployments confirms razor mesh fencing's operational superiority. The Hungarian border initiative documented a 99.3% intrusion prevention rate across 523km after installation, compared to 73% effectiveness with previous barriers. Correctional facilities in Texas reported a $1.2 million annual reduction in containment incident response costs following razor fence upgrades. Energy sector applications at Nigerian pipeline corridors saw sabotage attempts decrease from monthly occurrences to single annual incidents after razor barrier installation - achieving 96% threat reduction while maintaining accessibility for maintenance crews.

Final Thoughts on Razor Mesh Fence Solutions

Contemporary razor wire mesh fence implementations balance security imperatives with lifecycle economics through precision engineering. Advancements in galvanic coatings now ensure 30-year structural viability in aggressive environments without maintenance costs plaguing traditional fencing. Current procurement strategies should evaluate total ownership expenses rather than razor mesh fence

prices alone, acknowledging that certified systems deliver $9.20 ROI for every security dollar invested over 15-year operational periods. As intrusion methodologies evolve, multi-layered razor fence configurations incorporating passive detection remain the benchmark for critical asset protection worldwide.

(razor mesh fence)

FAQS on razor mesh fence

What is a razor wire mesh fence?

Q: What distinguishes a razor wire mesh fence from regular fencing?

A: A razor wire mesh fence features sharp-edged steel blades woven into galvanized mesh, creating an impassable barrier. It's designed for maximum perimeter security with visual deterrence and physical injury risks to intruders. Commonly used in military zones, prisons, and high-risk facilities.

How much does razor wire mesh fencing cost?

Q: What factors influence razor wire mesh fence prices?

A: Pricing depends on material gauge, height, coating (galvanized or PVC), and project scale. Installation complexity and geographic location also impact final costs. Request detailed quotes from suppliers for accurate razor mesh fence pricing tailored to your security needs.

Where should I install razor wire mesh fences?

Q: What applications are razor mesh fences best suited for?

A: These fences excel in high-security sites like correctional facilities, border checkpoints, and industrial plants. They're ideal for protecting critical infrastructure or deterring trespassing on private properties. Always verify local regulations before installing razor wire mesh fencing.

How durable are razor wire mesh fences?

Q: What lifespan can I expect from razor wire mesh fencing?

A: Properly maintained galvanized models withstand 15-20 years of harsh weather and corrosion. Stainless steel variants offer extended durability but increase razor wire mesh fence price. Regular inspections for damage or rust ensure optimal longevity and performance.

Can I install razor mesh fencing myself?

Q: Is DIY installation of razor wire mesh fences advisable?

A: Professional installation is strongly recommended due to injury risks and structural requirements. Specialized tools and safety protocols are mandatory for handling the razor-sharp components. Budget for expert installation when calculating total razor mesh fence prices.