Understanding Iron Wire Sizes A Guide for Enthusiasts and Professionals

Iron wire is a fundamental material used in a variety of applications, ranging from construction and electrical work to crafting and DIY projects. One of the critical factors to consider when selecting iron wire is its size, which can significantly affect its performance and suitability for specific tasks. This article will explore the implications of iron wire sizes, including their measurements, standards, and applications.

Iron wire is commonly measured in gauge sizes or diameter in millimeters or inches. The gauge system, particularly the American Wire Gauge (AWG) or Standard Wire Gauge (SWG), is widely used to denote the thickness of wires. In this system, a smaller gauge number indicates a thicker wire, while a larger gauge number indicates a thinner wire. For instance, an 8-gauge wire is thicker than a 12-gauge wire. Understanding these measurements is crucial, as they directly influence the wire's tensile strength and flexibility.

For those working with iron wire, the choice of size can depend on several factors, including the intended application. For heavy-duty applications, such as construction, thicker wires (lower gauge numbers) are preferred to ensure sufficient support and durability. Conversely, thinner wires are better suited for applications requiring more flexibility, such as in crafting or delicate electrical work.

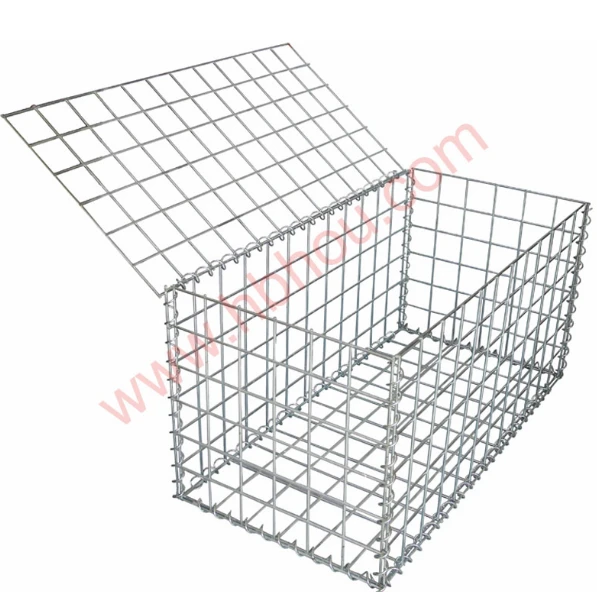

iron wire size

Another essential aspect to consider is the wire's tensile strength, which is its ability to withstand tension without breaking. Generally, larger diameter wires have higher tensile strength, making them ideal for applications where weight-bearing capacity is critical. Additionally, corrosion resistance is an aspect to keep in mind, as iron can rust when exposed to moisture. Therefore, for outdoor applications, galvanized or coated iron wires are recommended to enhance longevity.

When selecting iron wire, standard sizes are often predetermined by industry standards, making it easier to find suitable materials. Standard sizes range from 0.08 mm to 12 mm in diameter, with the most commonly used sizes varying based on specific applications. For example, in electrical wiring, sizes such as 0.5 mm and 1.0 mm are frequently utilized, while construction may involve larger sizes of up to 6 mm or more.

Moreover, advancements in technology have led to the production of iron wires with improved properties, such as higher strength-to-weight ratios and better corrosion resistance. These innovations are essential for specific industries that require reliable and durable materials.

In conclusion, understanding iron wire sizes is essential for selecting the right material for any project. By considering gauge measurements, tensile strength, and intended applications, both enthusiasts and professionals can make informed choices that enhance the quality and durability of their work. Consequently, whether you are building a structure, wiring an electrical device, or engaging in a crafting project, choosing the appropriate iron wire size can lead to successful outcomes and lasting results.