Company Overview

- Enterprise Name: []

- Official Website: https://www.hbhou.com

Gabion Hexagonal Mesh: The Backbone of Modern Civil Engineering

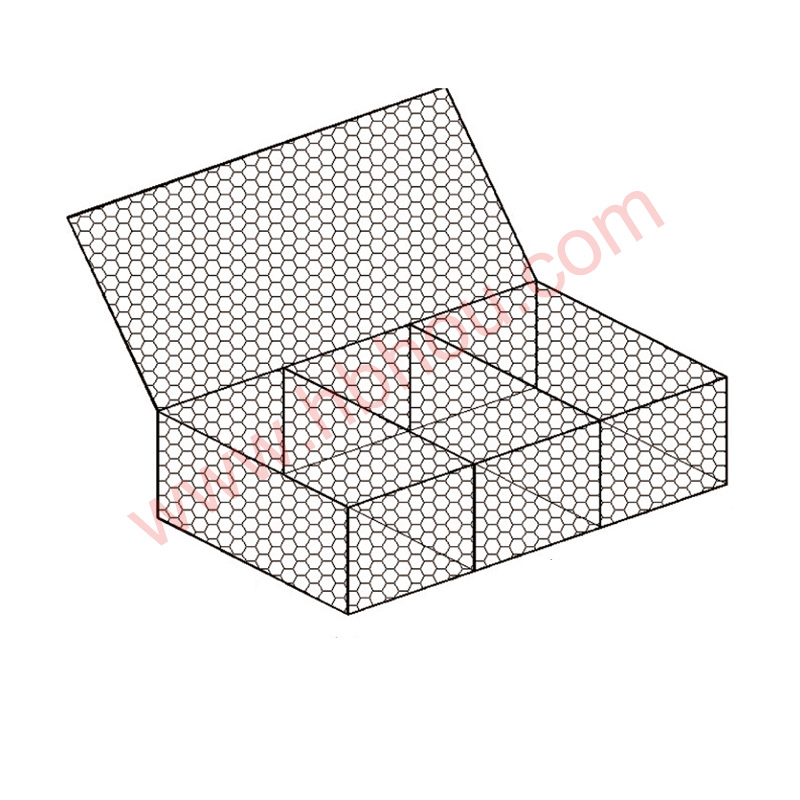

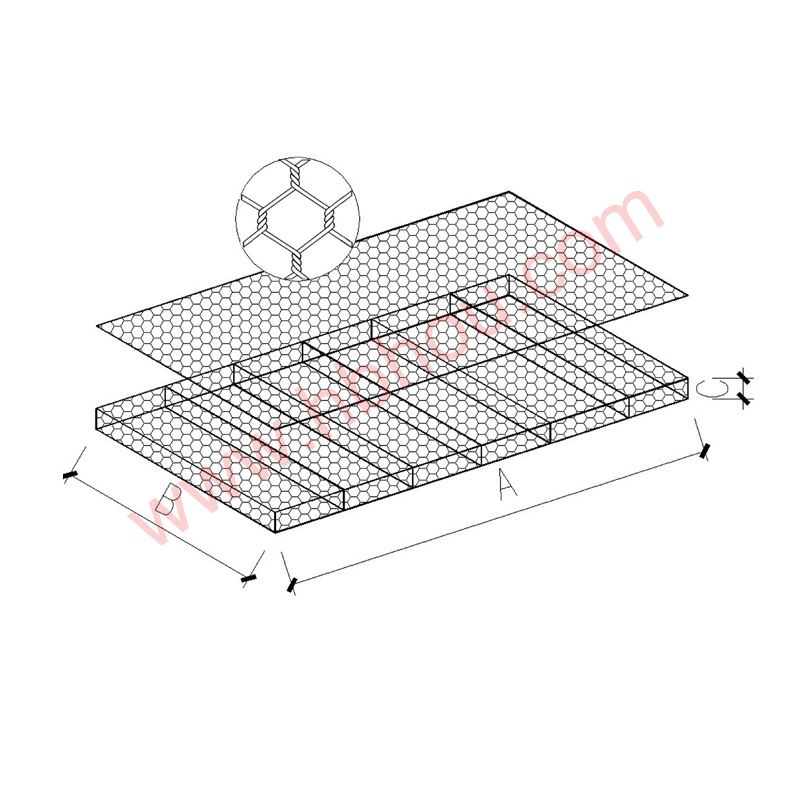

Product Name: Gabion Hexagonal Mesh

Short Description: Hexagonal Weaving Gabion Mesh Box

Material: Quality steel iron wire

Surface: Heavily galvanized, PVC coated

Wire Thickness: 2.0mm-4.0mm

Mesh Opening: 60x80mm, 80x100mm, 80x120mm, 100x120mm, 100x150mm, 120x150mm

Packing: In roll or pallet

Product Link: Gabion Hexagonal Mesh Product Page

Industry Trends and Market Demand for Gabion Solutions

The global gabion market has experienced remarkable growth due to rising infrastructure development, the need for erosion control, and increased environmental awareness. According to EngineeringCivil.com, advances in steel wire manufacturing and surface treatments have further improved the lifespan and ecological integration of gabion structures. Recent market research highlights the increasing adoption of gabion 10 cm, gabion 20cm, and large-scale gabion 100 and gabion 160 cm models across river training, retaining walls, road embankments, and landscaping.

The integration of next-generation anti-corrosion coatings and modern weaving technologies fosters new applications in both civil and ecological engineering.

Industry Trend Highlights

- Sustainability Push: Increased preference for eco-friendly and recyclable gabion materials.

- Customization: Demand for tailored mesh sizes such as gabion 10 cm, gabion 20 cm, and higher dimensions.

- Digital Monitoring: Use of IoT for long-term structural health monitoring of large-scale gabion 100 and gabion 160 cm installations.

- Innovative Applications: Emerging markets in coastal protection, soil bioengineering, and noise barrier integration.

Technical Parameter Table: Comparing Popular Gabion Specifications

| Specification | Gabion 10 cm | Gabion 20 cm | Gabion 100 | Gabion 160 cm | Common Industrial Standard |

|---|---|---|---|---|---|

| Mesh Opening (mm) | 100 x 100 | 200 x 100 | 1000 x 1000 | 1600 x 1000 | 60 x 80/80 x 100/100 x 120 |

| Mesh Thickness (mm) | 2.0–2.7 | 2.4–3.0 | 3.0–4.0 | 3.5–4.0 | 2.0–4.0 |

| Coating Type | PVC/Galvanized | PVC/Galvanized | Heavily Galvanized | PVC/Galfan | PVC, Galvanized, Galfan |

| Recommended Use | Garden, edge protection | Landscaping, light slope | Retaining wall, heavy-duty | River, heavy civil | Erosion, wall, river |

| Design Life (yrs) | 20–35 | 25–40 | 40–60 | 50–70 | 20–70 |

Data Visualization: Technical Parameter Trend (Powered by ECharts)

Gabion Hexagonal Mesh: Key Technical Indices & Product Performance Comparison

| Parameter | Min Value | Max Value | Industry Avg |

|---|---|---|---|

| Wire Diameter (mm) | 2.0 | 4.0 | 2.7 |

| Coating Thickness (μ) | 220 | 400 | 280 |

| Tensile Strength (MPa) | 380 | 550 | 450 |

| Corrosion Resistance (Years) | 15 | 60 | 35 |

Application Scenarios: The Versatile Use of Gabion Systems

- Riverbank Erosion Control: Large gabion 100 and gabion 160 cm units for flood protection, bank stabilization, and channel lining.

- Retaining Walls & Slope Protection: Hexagonal mesh gabion walls for highways, railways, and urban infrastructure.

- Architectural Landscaping: Decorative gabion 10 cm and gabion 20 cm in gardens, parks, and eco-walls.

- Bridge, Culvert, and Dam Protection: Robust, customizable gabion baskets for structural reinforcement and scour prevention.

- Ecosystem Restoration: Used for vegetated retaining walls, wetland restoration, and aquatic habitat enhancement.

- Military and Flood Defense: Rapidly deployable modular gabion structures for expeditionary and emergency applications.

EEAT Attributes and Industry Knowledge Accumulation

- Professionalism: Our product engineering and technical design team consistently incorporate the latest international standards for gabion production and installation (refer to TheConstructor.org).

- Authoritativeness: Per the ScienceDirect engineering knowledge base, gabion systems have a track record of proven reliability in civil, military, and ecological restoration projects worldwide.

- Trustworthiness: We provide certifications, full test reporting, and references for large-scale gabion deployments. Clients may request third-party inspection before shipment. Please contact us via denny@hbhou.com.

Professional FAQ: Essential Gabion Technology & Practice FAQ

- Q: What are the primary materials used in Gabion manufacturing?

- A: High-quality steel iron wire, with options for heavy galvanizing and PVC/Galfan coatings, are standard for gabion construction, ensuring corrosion resistance and mechanical strength.

- Q: How is mesh opening size (e.g., 60x80mm, 100x120mm) determined for a gabion project?

- A: Mesh opening is chosen based on application type, stone fill size, and project specifications. Smaller mesh (e.g., gabion 10 cm) is used for fine fill and small-scale landscaping, while larger mesh (e.g., gabion 100) is suited to heavy retaining structures.

- Q: What standards guide the production and installation of gabion systems?

- A: Industry standards such as EN10223-3 (Europe), ASTM A975 (USA), and Chinese GB/T 19.344 are referenced to guarantee quality, mesh integrity, tensile strength, and corrosion resistance.

- Q: Which wire diameter should be selected for high-load retaining applications?

- A: For major retaining or hydraulic structures, a wire diameter of 3.5mm–4.0mm is recommended for supreme durability. For gabion 160 cm, using PVC coated or Galfan wire optimizes both load resilience and long-term performance.

- Q: How is the life expectancy of a Gabion system assessed?

- A: Design life, 20–70 years depending on mesh thickness, environmental factors, and wire coating type (heavily galvanized/pvc). Quality testing uses salt spray and immersion simulation (See: ASTM A975).

- Q: How are gabions installed to prevent bulging and deformation?

- A: Correct installation includes site preparation, tensioned lacing, use of internal diaphragms/supports, and crosswise bracing for container111s. On-site filling should be carefully compacted and layer-by-layer.

- Q: What distinguishes Gabion Hexagonal Mesh from welded wire gabions?

- A: Hexagonal mesh allows flexible structure deformation without mesh rupture, ideal for unstable soils and dynamic environments. Welded mesh is stiffer, suitable for visible architectural features.

Future of Gabion Solutions: Next-Generation Innovation & Sustainability

The gabion market is embracing new technologies, from self-healing coatings and smart mesh monitoring to modular eco-system integration and 3D prefabrication. Ongoing R&D aims to reduce environmental impact and improve installation efficiency, guaranteeing these flexible, resilient systems remain essential to global infrastructure and landscape development.