The Versatility of Galvanized Iron Binding Wire

Galvanized iron binding wire is a vital component in countless applications, making it an indispensable tool in various industries. This wire, coated with a layer of zinc to enhance its corrosion resistance, has become increasingly popular due to its durability, strength, and versatility.

Composition and Manufacturing Process

Galvanized iron wire is produced by drawing iron wire through a galvanization process, where it is coated with zinc. This coating protects the iron from rust and other forms of corrosion, making it ideal for outdoor and industrial applications. The thickness of the zinc coating can vary, depending on the intended use of the wire. Generally, heavier coatings provide better protection in harsh environments.

Characteristics and Benefits

One of the primary benefits of galvanized iron binding wire is its remarkable strength-to-weight ratio

. This characteristic makes it easy to handle while providing necessary structural support. The wire can be easily bent, twisted, or shaped, allowing it to adapt to various requirements in construction, agriculture, and crafting.Another significant advantage is its resistance to weathering. In outdoor settings, galvanized wire holds up exceptionally well against moisture, UV rays, and temperature fluctuations. This resistance reduces maintenance costs and prolongs the lifespan of constructions such as fences, trellises, and garden supports.

Applications in Various Industries

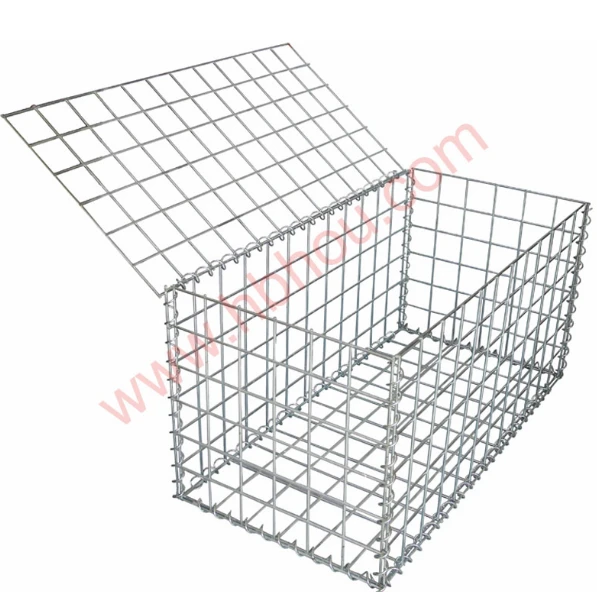

galvanized iron binding wire

Galvanized iron binding wire finds applications across multiple sectors. In the construction industry, it is frequently used for tying rebar in concrete structures, ensuring that the concrete maintains its integrity and strength. It is also used for creating frameworks for plastering, thereby ensuring that the final product has a solid foundation.

In agriculture, galvanized binding wire is often employed for various fencing solutions. It provides a reliable and durable option for animal enclosures and garden trellises. Additionally, it's used for securing plants, tying up vines, and creating support structures for crops. The wire’s resistance to rust makes it ideal for use in wet or humid conditions, which are common in agricultural settings.

The crafting and DIY community also benefits from galvanized iron binding wire. Crafters often use it in jewelry making, sculpture, and other artistic projects, as it can be easily manipulated to create intricate designs. The wire is available in various gauges, allowing artists to choose the right thickness for their specific projects.

Environmental Considerations

As galvanization involves the coating of iron wire with zinc, it is essential to consider environmental impacts. The zinc used in the galvanization process can be recycled, and innovative methods are continuously being developed to minimize the ecological footprint of zinc production. Many manufacturers are now adhering to sustainable practices, ensuring that the production of galvanized binding wire has a minimal impact on the environment.

Conclusion

In summary, galvanized iron binding wire is a remarkable material that exhibits versatility across numerous industries. Its strength, durability, and resistance to corrosion make it an ideal choice for construction, agriculture, and crafting applications. As industries continue to innovate and prioritize sustainability, galvanized iron binding wire will undoubtedly maintain its relevance and importance in the modern world. Whether you are a contractor, farmer, or craftsman, this boundless wire offers the reliability needed to support your projects, making it a staple in everyday use.