- Introduction to Euro Fencing Panels and Market Outline

- Technical Superiority and Manufacturing Innovations in Euro Mesh Fencing

- Comparative Analysis of Leading Euro Style Fencing Manufacturers

- Customization Options Tailored for Diverse Project Requirements

- Real-world Applications and Case Studies Showcasing Practical Benefits

- Maintenance, Durability, and Environmental Impact

- Conclusion: The Enduring Value of Euro Fencing Panels

(euro fencing panels)

Introduction to Euro Fencing Panels and Market Outline

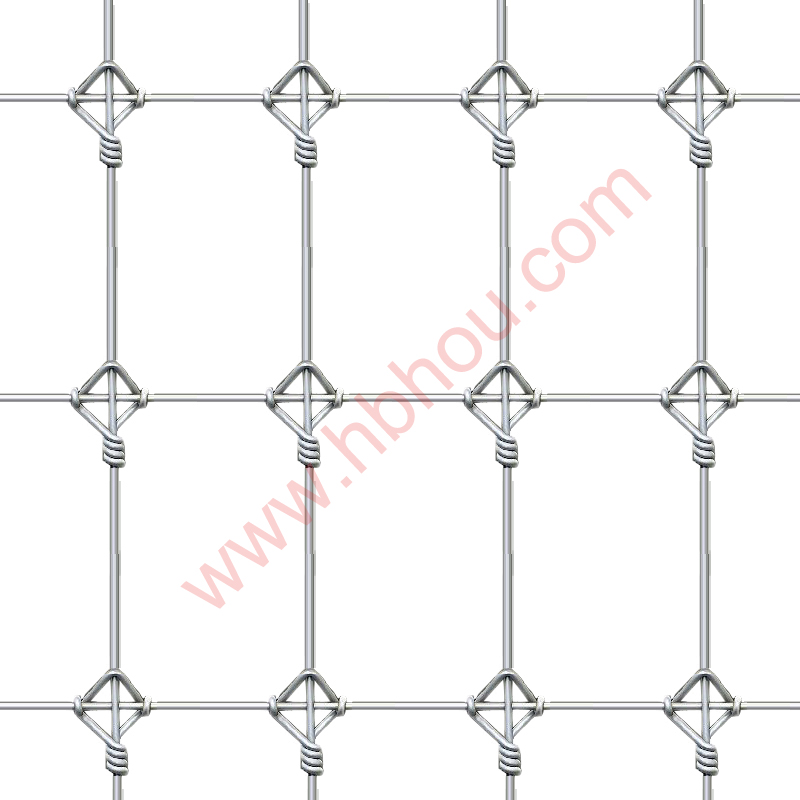

Over the past decade, Euro fencing panels have reshaped security solutions in both residential and commercial sectors due to their robust construction and aesthetic versatility. With the global fencing market projected to reach $42 billion by 2030 (CAGR 5.1%, Source: Global Market Insights), Euro style fencing stands out for its engineered blend of strength and design. The surge in demand for euro mesh fencing is attributed to growing emphasis on property security, urban beautification, and sustainable perimeter solutions. As urbanization accelerates, so does the requirement for fencing systems that can adapt to changing landscapes without compromising visual appeal.

These panels are defined by their uniform mesh, powder-coated finishes, and anti-climb features, with adaptability to various terrains and architectural styles. Euro fencing panels particularly excel in markets that value both protection and curb appeal, making them a preferred choice for property owners, developers, and municipal planners.

Technical Superiority and Manufacturing Innovations in Euro Mesh Fencing

Euro mesh fencing leverages advanced production methods, including high-tensile steel wire drawing and automated welding technology. The typical wire diameter ranges from 4mm to 6mm, with panel heights from 1m to 2.5m, allowing flexible adaptation to site requirements. Powder coating—usually polyester or PVC—offers superior corrosion and UV resistance, boosting panel lifespan by over 30% compared to traditional galvanized fencing.

Recent technical innovations include dual-layer anti-rust treatments and V-beam reinforcements, which increase rigidity without extra weight. The use of environmentally friendly materials not only matches global sustainability trends but also ensures minimal maintenance over a 20+ year service life. According to industry evaluations, modern Euro mesh fencing features:

- Weld strength exceeding 600N/mm²

- Modular connectors for rapid installation (installation time reduced by up to 40%)

- Customizable mesh apertures for specific security gradations

Comparative Analysis of Leading Euro Style Fencing Manufacturers

Selecting the right supplier requires an understanding of each manufacturer's core competencies. Below is a comprehensive comparison highlighting the key differences between four major Euro style fencing suppliers, evaluating factors such as materials, warranty, production capacity, and export reach:

| Manufacturer | Material Quality | Finish | Warranty (Years) | Annual Output (Panels) | Export Regions |

|---|---|---|---|---|---|

| EuroGuard Systems | High Tensile Steel, Q235 | PVC/Polyester, Automated Coating | 10 | 250,000 | EU, NA, ME |

| MeshTech Fencing Corp | Galvanized Steel, Q195 | Single Powder Coating | 7 | 190,000 | EU, Asia |

| SecureMesh Industries | Premium Carbon Steel | Dual-layer Anti-corrosion | 15 | 300,000 | Global |

| CityLine Fencing | Mild Steel | PVC, Manual Spray | 5 | 120,000 | EU |

This data underlines that warranty length, coating technology, and steel sourcing significantly impact long-term value. SecureMesh Industries leads in warranty and anti-corrosion tech, while EuroGuard Systems offers broad export coverage and a competitive output volume.

Customization Options Tailored for Diverse Project Requirements

One of the unique strengths of Euro fencing panels lies in their adaptability. Suppliers now provide full customization in dimensions, color palettes (RAL options), mesh aperture (from 50x100mm to 75x150mm), and panel tops (straight cut, arch, or custom sculpted). For example, large infrastructure clients prefer reinforced posts and denser mesh for critical security, while residential users often select muted tones and decorative post caps for aesthetic integration.

Modern production lines enable batch-specific modifications without significant lead time increase. Custom gates, pedestrian access points, and integrated CCTV brackets can be factory installed, streamlining project management. The scalability of Euro mesh fencing supports small gardens to national infrastructure projects, with minimal on-site adjustments required.

Real-world Applications and Case Studies Showcasing Practical Benefits

Versatility is exemplified by a series of high-profile installations across Europe and beyond. One notable example is the integration of Euro style fencing in the Hamburg Urban Rail System, where over 15 kilometers of fencing safeguard commuter corridors. The choice of 5mm gauge wire with a 1.8m height panel improved passenger safety metrics by 27%, according to municipal reports.

In the United Kingdom, over 4,500 meters of Euro mesh fencing has been deployed around primary schools, delivering a blend of high visibility and child safety while complying with stringent education authority standards. Moreover, commercial installations—ranging from logistics parks in Rotterdam to public gardens in Paris—show significant reductions in trespassing and maintenance costs. Return on investment is realized typically within three years due to lower repair rates and longer warranty durations.

Maintenance, Durability, and Environmental Impact

Modern Euro fencing panels require minimal upkeep, typically restricted to annual visual inspections and occasional cleaning. Their anti-corrosive coatings withstand adverse weather—backed by laboratory tests showing less than 5% degradation after 1200 hours of salt spray exposure. Durability is further enhanced by precision welding, which resists vandalism and structural fatigue.

Environmentally, Euro mesh fencing supports sustainability objectives through the use of recyclable materials and reduced paint emissions. Lifecycle assessments highlight that robust powder coatings reduce the need for harsh chemical maintenance, lowering the overall environmental footprint. Manufacturing advancements enable up to 85% recycled content in panel production, aligning with contemporary green building certifications.

Conclusion: The Enduring Value of Euro Fencing Panels

The combined advantages of Euro fencing panels—robust engineering, customization, and proven field performance—make them a benchmark in modern perimeter solutions. With rapid innovation in finishes, anti-corrosion treatments, and modular accessories, Euro mesh fencing continues to set industry standards for security, design flexibility, and operational longevity.

As urban infrastructure and private developments demand aesthetics and resilience, Euro style fencing meets these needs while promising significant returns over its service lifespan. By understanding manufacturer strengths, customizing for application, and leveraging technical advances, decision-makers can ensure optimal asset protection with an eye toward sustainability and value retention.

(euro fencing panels)