Understanding Electrical Wire Construction

Electrical wire construction is a fundamental aspect of electrical engineering and is crucial for the safe and efficient transmission of electricity in various applications. Whether in residential, commercial, or industrial settings, the design and composition of electrical wires play a significant role in ensuring that electrical systems function properly without posing hazards.

Fundamental Components

At its core, an electrical wire consists of two primary components the conductor and the insulation. The conductor is typically made of copper or aluminum, materials known for their excellent electrical conductivity. Copper is often favored due to its superior conductivity and reliability, while aluminum is lighter and less expensive, making it suitable for specific applications.

The insulation surrounds the conductor and serves several critical purposes. It prevents electrical leakage, protects against short circuits, and safeguards users from electric shocks. Additionally, insulation is designed to withstand environmental factors such as moisture, temperature fluctuations, and chemicals. Common materials for insulation include polyvinyl chloride (PVC), polyethylene, and rubber, each chosen for its specific properties and intended use.

Types of Electrical Wires

Electrical wires come in various types, each designed for particular applications. The two most common types are non-metallic sheathed cable (NM cable) and armored cable (AC). NM cable is widely used in residential wiring due to its flexibility and ease of installation. It consists of two or more insulated conductors and a ground wire enclosed in a plastic sheath.

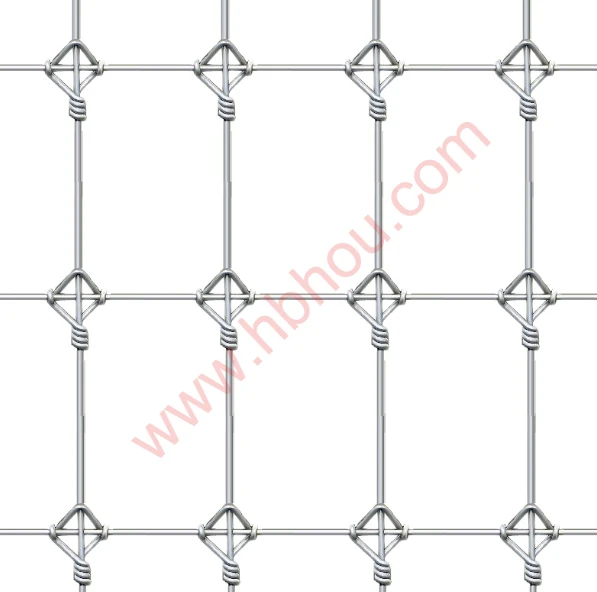

In contrast, armored cable is designed for environments where additional protection is required, such as commercial or industrial settings. It features a layer of steel or aluminum armor, which provides enhanced durability against physical damage while maintaining the integrity of the insulated conductors inside.

electrical wire construction

Wire Gauge and Its Importance

Wire gauge is a critical factor in electrical wire construction. Measured in American Wire Gauge (AWG), the gauge number indicates the wire's thickness. A lower gauge number signifies a thicker wire, which can carry more current without overheating. This is particularly important in applications where high electrical loads are expected.

Using the correct wire gauge is essential to avoid potential hazards. An under-sized wire may overheat, leading to insulation failure and possible fires. Conversely, an oversized wire can be unnecessarily expensive and challenging to work with. Therefore, selecting the proper gauge based on the expected load and distance is crucial for safe and efficient electrical installations.

Regulatory Standards

Manufacturers of electrical wires must adhere to various regulatory standards to ensure safety and performance. In the United States, the National Electrical Code (NEC) sets forth guidelines for electrical installations, including wire construction. Compliance with these standards helps ensure that electrical systems are safe, reliable, and functional.

Additionally, organizations such as the Underwriters Laboratories (UL) test and certify electrical products, including wiring, to verify their safety and performance under set conditions. When selecting electrical wire, it is essential to look for certifications from reputable testing organizations to ensure compliance with safety standards.

Conclusion

Electrical wire construction involves a combination of materials, design considerations, and adherence to safety standards. Understanding the components of electrical wires, the types available, the significance of wire gauge, and the regulatory framework is vital for anyone involved in electrical work. Whether you’re a professional electrician, a contractor, or a DIY enthusiast, appreciating the intricacies of electrical wire construction ensures not only the functionality of electrical systems but also the safety of those who use them. As technology advances and electrical demands evolve, staying informed about developments in wire construction will be key to meeting future challenges in the industry.