Understanding 12 Foot Corral Panels: A Global Perspective

At first glance, 12 foot corral panels might seem like just another livestock management tool, a niche bit of hardware used on farms or in ranches. But zoom out a little and their significance becomes clearer — across continents and industries, these panels play a vital role in animal husbandry, disaster relief efforts, and even industrial logistics. Globally, as agricultural practices modernize and humanitarian needs grow increasingly urgent, understanding the design and deployment of such solutions offers clear benefits for operators, NGOs, and governments alike.

According to the Food and Agriculture Organization (FAO), livestock is a backbone for more than 600 million rural poor worldwide, and proper animal containment is crucial for both economic stability and animal welfare (1). Panels that measure about 12 feet, or roughly 3.6 meters, strike a balance between portability, sturdiness, and ease of use. They help create corrals and enclosures that are scalable to different environments — from vast ranches in the US to remote pastoralist communities in Africa.

What Exactly Are 12 Foot Corral Panels?

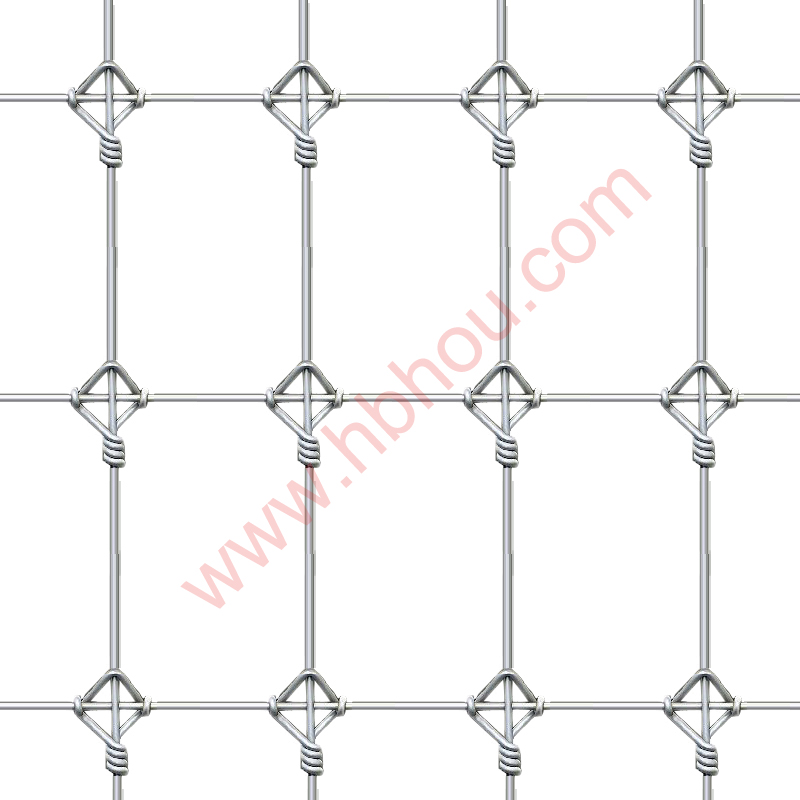

Simply put, 12 foot corral panels are modular fencing sections, usually made from steel pipe or heavy-duty steel mesh, designed to connect and form temporary or permanent enclosures for livestock. Their length of around 12 feet offers a manageable size for one or two people to install, yet they provide enough span to minimize the number of panel connections and thus weak points.

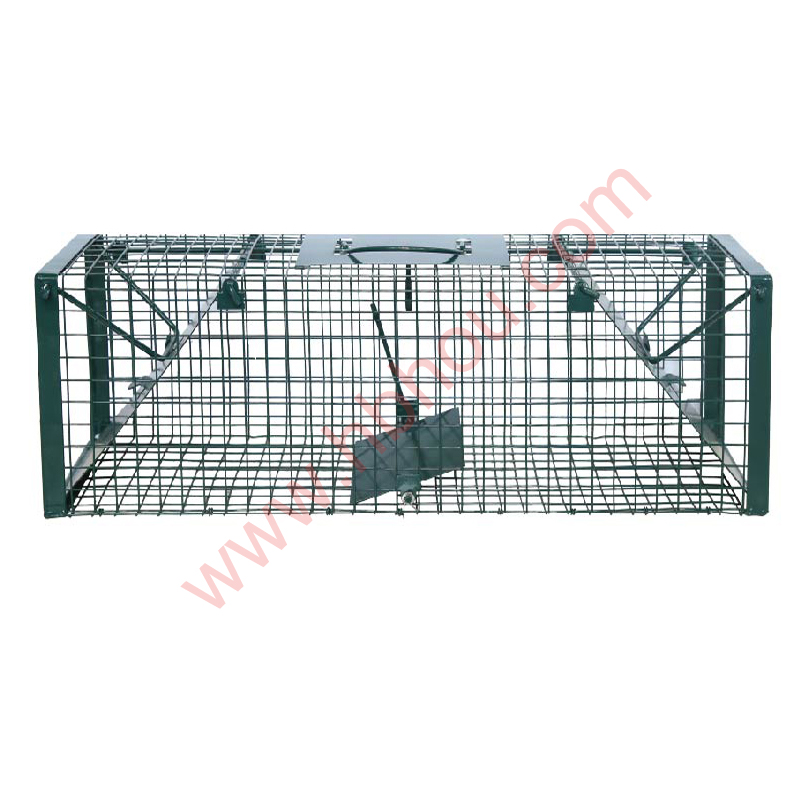

These panels meet a broad spectrum of needs — in agriculture, they allow for the smooth handling and sorting of cattle, sheep, or goats; in humanitarian or disaster response scenarios, they’re sometimes repurposed as barriers or temporary holding pens for stray animals. The appeal is their rugged durability combined with surprisingly flexible configurability.

Core Features That Define Their Practical Usefulness

1. Durability & Material Quality

It’s no secret that these panels face tough conditions — sun, rain, mud, dust, even the occasional stubborn bull. Hence, they’re generally constructed from galvanized steel or powder-coated finishes that withstand corrosion and abrasion. A panel that lasts 10+ years is a common benchmark.

2. Scalability & Modularity

The beauty of 12 foot corral panels is how easily they interconnect with standard clamps or pins. Expand the corral size? Just add more panels. Need a smaller containment? Use fewer. It enables rapid setup adjustments depending on the herd size or available space.

3. Portability and Ease of Deployment

One or two workers can carry and position these panels without specialized equipment. This is a game-changer especially in remote or hard-to-access locations — imagine rugged terrain or a disaster zone where heavy machinery isn’t an option.

4. Cost Efficiency

Compared to permanent fencing or complex enclosure systems, these panels provide a lower upfront investment and fewer maintenance headaches. Plus, their reusability over multiple seasons or deployments means better long-term value.

5. Safety for Animals and Handlers

Well-designed panels reduce risk by preventing animals from getting stuck or injured on sharp edges, and the spacing of bars is calibrated to avoid hoof or limb entrapment. For livestock handlers, this means fewer injuries and smoother workflow.

Mini takeaway: The combination of durability, portability, and cost-effectiveness is why these panels remain an industry staple — not just in farming but also in broader animal management contexts.

Global Applications & Real-World Use Cases

Where does one find these panels in action? Pretty much everywhere livestock is part of the equation. In the American West, ranchers rely on 12 foot corral panels to build pens, chutes, and sorting systems that can be adjusted daily to fit the herd dynamics.

In East Africa, NGOs facilitating pastoralist livelihoods purchase panels to help contain animals during vaccination campaigns or drought-induced migration controls. In Australia’s vast outback, the portability helps team members set up temporary enclosures during mustering.

On a rather different note, some disaster relief agencies have used these panels to control animal movement following floods or earthquakes, preventing stray cattle or horses from wandering into hazardous zones or roads.

Product Specification Table

| Specification | Typical Value | Notes |

|---|---|---|

| Panel Length | 12 feet (3.66 meters) | Standard size for modular flexibility |

| Material | Galvanized steel / Powder-coated steel | Corrosion-resistant coatings for longevity |

| Weight (approx) | 30-45 kg (66-99 lbs) | Depends on gauge and panel style |

| Height | Approximately 5-6 feet | Sufficient for most cattle and sheep |

| Connection Method | Bolt clamps or quick pins | Allows fast assembly and disassembly |

Comparing Vendors for 12 Foot Corral Panels

| Vendor | Build Quality | Price per Panel | Shipping Regions | Customization Options |

|---|---|---|---|---|

| RanchPro Supplies | High | $110 | USA, Canada | Yes (colors, heights) |

| AgriSteel Panels | Medium-High | $85 | Worldwide | Limited (standard sizes only) |

| EcoFarm Innovations | High (Eco-coating) | $130 | USA, EU | Yes (eco-friendly materials) |

Why Use 12 Foot Corral Panels? The Advantages and Long-Term Value

Economics often drive decisions in livestock management, and these panels serve both the budget-conscious smallholder and large-scale operator alike. They deliver strong value over time; initial costs are balanced by durability and the ability to be repurposed season after season.

There's also an important safety factor. Well-constructed panels reduce stress on animals, which in turn helps preserve weight and overall health — essential for maximizing profitability. Handlers benefit too from ergonomically sized panels that reduce injury risks and speed up workflow, making daily tasks less taxing.

Emotionally, the feeling of trust in your equipment counts for a lot — it’s “the one thing you can count on” when stockmanship demands precision. As innovation nudges forward, the integration of more sustainable finishes and recyclable materials adds a socially responsible dimension to these panels’ appeal.

On the Horizon: Future Trends in Corral Panel Design

One can’t ignore the push towards greener manufacturing. Companies are experimenting with low-impact steel production or hybrid materials incorporating recycled plastics for lightness and rust resistance. Digitally, some vendors are developing augmented reality apps to help ranchers plan corral layouts before physically rolling out panels.

Another interesting shift is automation. Though it sounds futuristic, robotic handlers that position and assemble panels could become a reality — a boon for large livestock operations struggling with labor shortages.

Overcoming the Challenges with Innovative Solutions

Despite their popularity, 12 foot corral panels aren’t perfect. Issues include logistics hurdles in remote areas where shipping bulky panels is costly or slow. Also, cheaper panels sometimes fall short on quality and durability, leading to costly replacements.

One solution gaining traction is modular kits that pack flat for transport, supplemented by onsite assembly of reinforced frames. And more manufacturers now offer heavy-duty or lightweight series tailored to specific climates or animal types.

Frequently Asked Questions About 12 Foot Corral Panels

- Q: How easy is it to move and set up 12 foot corral panels?

A: Generally, these panels are designed for fast deployment. One or two people can typically move and connect a panel in under 10 minutes, depending on ground conditions and tools available. - Q: What animals are best suited for containment with these panels?

A: While primarily used for cattle, these panels work well for sheep, goats, and sometimes horses. Height and bar spacing might need adjustment for specific species. - Q: Are there eco-friendly corral panel options?

A: Yes, some manufacturers offer panels with recycled steel content and eco-coatings that reduce environmental impact over the product lifecycle. - Q: How long should I expect these panels to last outdoors?

A: Depending on the material and maintenance, high-quality galvanized panels can last over 10 years in typical outdoor conditions. - Q: Can I customize panel sizes or finishes?

A: Many vendors provide custom lengths, heights, and color coatings. It’s worth asking at purchase to tailor panels to your exact needs.

Wrapping It Up: Why 12 Foot Corral Panels Still Make Sense

At the end of the day, the popularity of 12 foot corral panels isn’t just about tradition — it’s practical. They blend portability, durability, and flexibility in a package that’s stood the test of time globally. Whether you’re an experienced rancher, a relief organization, or just curious about robust animal management solutions, there’s good reason to consider these panels.

For those interested in exploring options or getting expert advice, visit our partner suppliers at 12 foot corral panels. It’s a starting point for better livestock handling that’s both smart and sustainable.