Understanding 12 Foot Fence Panels: Why They Matter Worldwide

If you’ve ever stood next to a fence that seemed especially tall and sturdy, you might have encountered what the industry calls 12 foot fence panels. They're not just longer versions of your garden fence; these robust barriers pack a punch in security, safety, and practicality. Globally, these panels play a critical role in everything from managing sensitive industrial sites to creating secure perimeters in humanitarian aid zones, especially in areas prone to unrest or natural disasters. Understanding these panels, their uses, and their evolving benefits isn’t just for contractors or suppliers — it impacts how communities secure assets, how governments protect borders, and how NGOs create safe spaces.

---

The Global Context of 12 Foot Fence Panels

The demand for reliable fencing solutions—especially taller, more resilient panels—is growing worldwide. According to the International Organization for Standardization (ISO), there has been a noticeable uptick over the last decade in the use of modular fencing systems for industrial and security purposes (1). Why? Well, as urban areas expand and industries become more complex, the need to demarcate and protect property is undeniable.

Think about it: outdoor facilities in harsh weather, border zones with fluctuating security needs, or even construction sites demanding quick setup and takedown. Problems like theft, trespassing, and liability risks push facility managers to look for fencing solutions that are not only stronger but adaptable to varying environments. The 12 foot fence panel, thanks to its height and modular design, fits perfectly into this demand curve, offering a practical yet formidable barrier.

---

What Exactly Are 12 Foot Fence Panels?

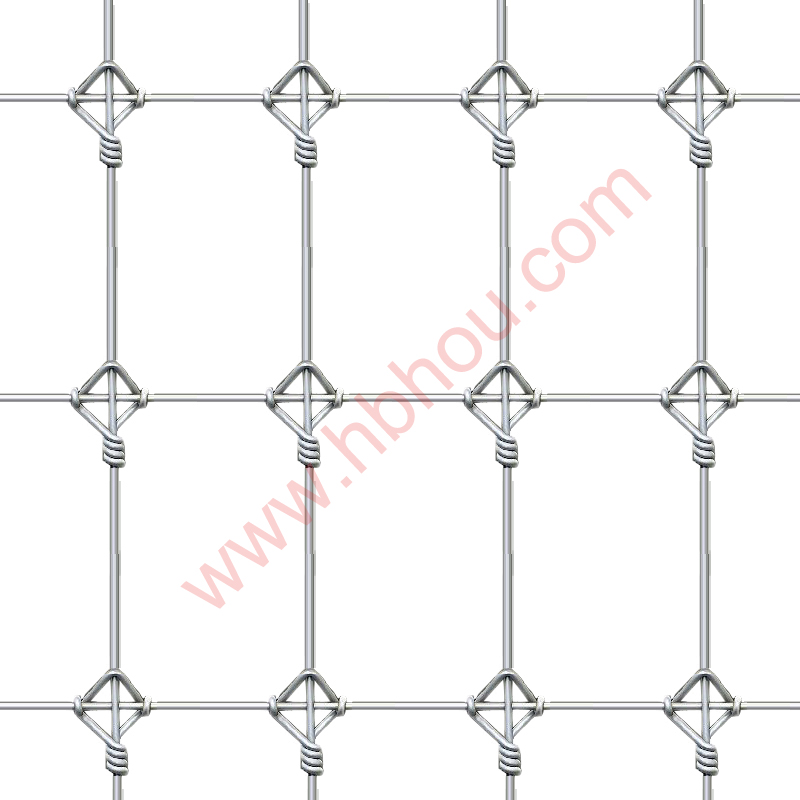

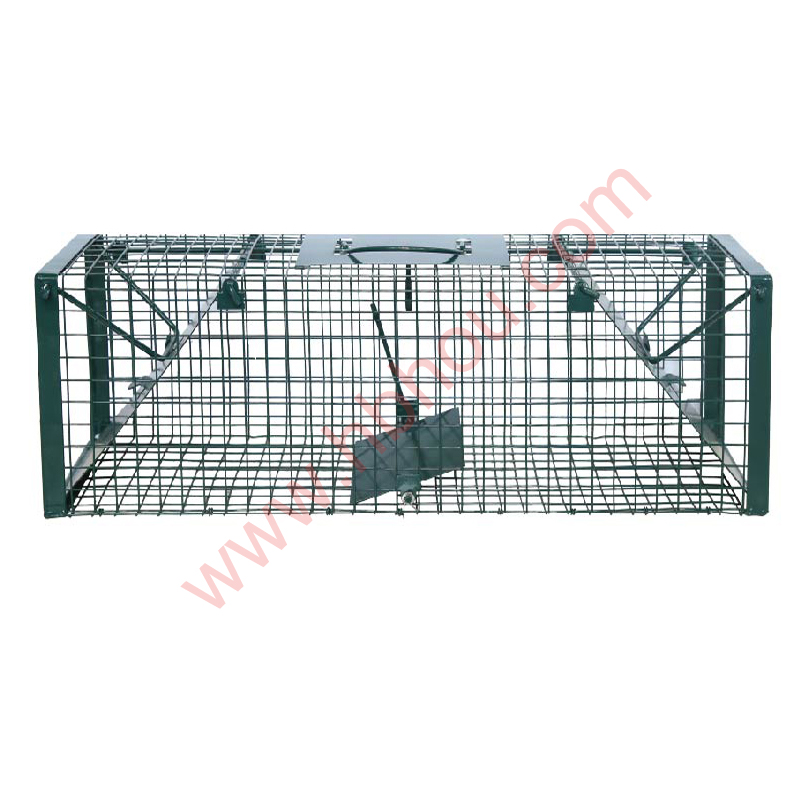

In straightforward terms, a 12 foot fence panel is a pre-fabricated fencing section that is 12 feet in length, often with a height around 6 to 8 feet, designed for easy installation and modular scalability. These panels consist commonly of steel or aluminum mesh, sometimes reinforced with welded wire or chain link, depending on the need. The “panel” concept means each section is a ready-to-go piece, simplifying logistics while enhancing customization.

This type of fencing isn’t just another home improvement project; it’s an industrial-grade, scalable solution that plays vital roles in many sectors—from securing remote mining sites in Australia to sorting logistics yards in Europe, or even marking safe zones for displaced communities.

---

Key Features That Set 12 Foot Fence Panels Apart

Durability

The panels are often galvanized or powder-coated to fight rust and corrosion—essential if you’re in a humid jungle or cold northern climate. Many also come with extra durability against UV rays or chemicals, which means less maintenance and longer lifespans.

Scalability & Modularity

One panel can be installed or removed with minimal fuss, allowing fences to stretch or shrink as per changing requirements. This flexibility is practical for temporary sites or evolving boundaries.

Cost Efficiency

Despite their heavy-duty build, 12 foot fence panels tend to reduce labor costs significantly. With fewer posts needed due to the length, and modular design minimizing time needed for assembly, project budgets can stretch further.

Security & Privacy

Higher panels mean better deterrence for trespassers and animals. When combined with privacy slats or additional mesh layers, they also help block sight lines, protecting sensitive areas from unwanted eyes.

Portability

Since these are often designed to be temporarily installed, many times for events or disaster zones, they can be boxed, shipped, and set up again elsewhere — a massive benefit for organizations needing both speed and efficiency.

Mini Takeaway:

These core traits show that 12 foot fence panels aren’t simply bigger fences—they’re strategic, versatile tools that solve modern fencing problems in practical ways.

---

How 12 Foot Fence Panels Are Used Around the World

These panels come up in all sorts of fascinating scenarios. For example:

-

Disaster Relief Zones: After floods or earthquakes, NGOs rapidly deploy fencing to secure camps and supply areas, ensuring safety and order.

-

Industrial Sites: Remote oil rigs or mining areas rely on these panels to keep unauthorized personnel out while withstanding harsh environments.

-

Urban Development Projects: Construction companies use them to protect new developments from vandals or accidental intrusion.

-

Border Security: Longer fencing sections reduce gaps and improve monitoring efficiency for customs agencies.

In parts of Africa and Asia, where humanitarian aid often requires quick yet stable fencing, these panels balance cost, durability, and simple logistics. It’s a bit like having a portable wall you can build around your most precious resources.

---

Advantages of Choosing 12 Foot Fence Panels for Long-Term Projects

Here’s what’s compelling once you think long-term:

-

Reduced Maintenance: Fewer posts and robust materials mean less intense upkeep.

-

Environmental Sustainability: Many manufacturers now use recycled metals and eco-friendly coatings.

-

Social Impact: Providing secure, controlled environments improves safety for workers, residents, or evacuees.

-

Reliability Under Stress: Designed to hold up in storms and rough handling without warping or collapsing.

-

Scalability in Action: As projects grow or shrink, fences can be added or removed without replacing entire systems.

Emotionally, it’s reassuring for site managers or residents alike to see a structure that promises safety and respect for boundaries, even if the stakes are high.

---

Product Specification Table

| Feature |

Specification |

Notes |

| Length |

12 feet (3.66 m) |

Standardized panel length |

| Height |

6 to 8 feet (1.83–2.44 m) |

Custom heights available |

| Material |

Galvanized steel, aluminum |

Powder coated option for weather resistance |

| Weight |

~40 to 60 kg (varies by design) |

Easily handled by 2-person teams |

| Installation |

Bolted or clipped to posts |

Modular and reusable |

---

Looking Ahead: Innovations in 12 Foot Fence Panels

The future feels promising. Some emerging trends include:

-

Smart Fencing: Embedded sensors alert security teams of breaches in real time.

-

Eco-Materials: Biodegradable coatings or recycled metals minimize environmental impact.

-

Modular Automation: Panels that can self-lock or adapt their shape via robotics.

-

Integrated Lighting: Panels that incorporate solar-powered LEDs for nighttime visibility.

These innovations promise to make fences not just barriers, but active parts of a facility’s security system.

---

Vendor Comparison: Choosing The Right Supplier

| Vendor |

Material Options |

Customization |

Typical Lead Time |

Ideal Use Cases |

| FenceCo Pro |

Galvanized Steel, Aluminum |

High – custom panel sizes, coatings |

4–6 weeks |

Industrial, Commercial Security |

| SafePanels Ltd. |

Powder-Coated Steel, Plastic Composite |

Moderate – colors, finishes |

2–4 weeks |

Event Security, Temporary Barriers |

| EcoFence Solutions |

Recycled Metals, Green Coatings |

Low – standard panels only |

6–8 weeks |

Sustainable Infrastructure Projects |

---

Overcoming Challenges in Using 12 Foot Fence Panels

Certainly, there are hurdles. The size means heavier panels, which can complicate transport in remote areas. Also, initial cost outlays might seem steep for small-scale projects. Some users report installation difficulty where terrain is uneven or constrained.

The good news is ongoing design improvements mitigate these issues: lighter alloys, integrated leveling mounts, and optimized packing for shipping. Consulting with experts during planning also prevents costly mistakes later.

---

Frequently Asked Questions About 12 Foot Fence Panels

- How difficult is it to install 12 foot fence panels compared to smaller panels?

- While the longer panels require two or more people for safe handling, installation can actually be faster due to needing fewer posts and fewer connections. Pre-drilled holes and modular fittings usually make the process smoother.

- Are these panels suitable for coastal environments?

- Yes, many 12 foot fence panels are galvanized or powder-coated to resist rust and corrosion caused by salty sea air, but it’s important to choose materials designed specifically for marine use.

- Can 12 foot fence panels be customized for height or color?

- Absolutely. Most suppliers offer variations in height, coatings, and colors to match project specifications or comply with regulatory needs.

- What sort of maintenance do these panels require?

- Typically, minimal. Occasional washing and inspections for damage are enough. Powder coatings help prevent corrosion, extending lifespan substantially.

- Are 12 foot fence panels a good choice for temporary fencing needs?

- Definitely. Their modular, reusable nature means they are ideal where speed, flexibility, and security are priorities—think festivals or emergency response zones.

---

Conclusion: Why 12 Foot Fence Panels Are a Smart Investment

Ultimately, these longer fence panels represent more than just extended length — they embody a solution that is cost-effective, scalable, and durable. Whether securing industrial property or establishing safe zones in humanitarian crises, the value is clear. If you’re looking to upgrade a project or simply curious, consider how 12 foot fence panels can adapt to your needs in a practical, reliable manner.

To explore quality options and get expert advice, visit

12 foot fence panels and discover how these panels fit into your security or project plans.

---

References

- International Organization for Standardization (ISO): Security Fencing

- Wikipedia: Fence

- World Bank Report on Urban Security Management