As the demand for humane animal control grows globally, heavy duty live traps have become indispensable across several industries, from urban pest management to ecological research and commercial agriculture. Product innovation like the Green Double Door Live Wild Animal Trap Cage is propelling the competitive landscape, ensuring safety, efficiency, and sustainability.

Market Trends & Application Scenarios for Heavy Duty Live Traps

The global market for heavy duty live animal traps is projected to grow at a CAGR of 5.2% through 2028, driven by increasing demands for humane wildlife management in both urban and rural environments[1]. Regulatory shifts favoring humane capture over lethal methods, and growing research in ecological monitoring, are fueling adoption across industries.

- Urban pest control: Managing raccoon invasions, feral cats, and groundhogs near residential complexes

- Agriculture & animal husbandry: Protecting farms from nuisance animals without injury

- Industrial/Infrastructure: Pipeline areas, electrical substations—protection from wildlife-induced faults with minimum ecological impact

- Environmental research: Population monitoring for conservation efforts

- Municipal works: Humane cohabitation in cities abutting wildlife corridors

Technical Parameters & Industry-Leading Specifications

Key Performance Table: Heavy Duty Live Traps Industry Offerings Comparison

| Model | Material | Dimensions (L×W×H, cm) | Wire Diameter | Door Mechanism | Load Capacity | Certifications |

|---|---|---|---|---|---|---|

| Green Double Door Live Wild Animal Trap Cage | Galvanized Q235 Steel, PVC Coated | 100 × 27 × 30 | 3.5 mm | Double Door, Spring Loaded | Up to 20 kg | ISO 9001, RoHS |

| EZ-Catch Pro XL | 304 Stainless Steel | 92 × 28 × 32 | 3 mm | Single Door, Gravity Trap | 16 kg | ANSI Z245, CE |

| SafeGuard HD Cage | Powder-coated Steel | 110 × 32 × 34 | 4 mm | Double Door, Push Plate | 24 kg | ISO 14001 |

| Wildwise Raccoon ProTrap | Galvanized Steel | 98 × 29 × 29 | 3.8 mm | Spring Mechanism | 18 kg | EPA registered |

Top Materials Proportion in Heavy Duty Live Traps

Load Capacity by Door Mechanism

Corrosion Resistance in Industry Tests (1000hr Salt Spray, % Integrity)

Manufacturing Process of Heavy Duty Live Animal Traps: Excellence in Every Phase

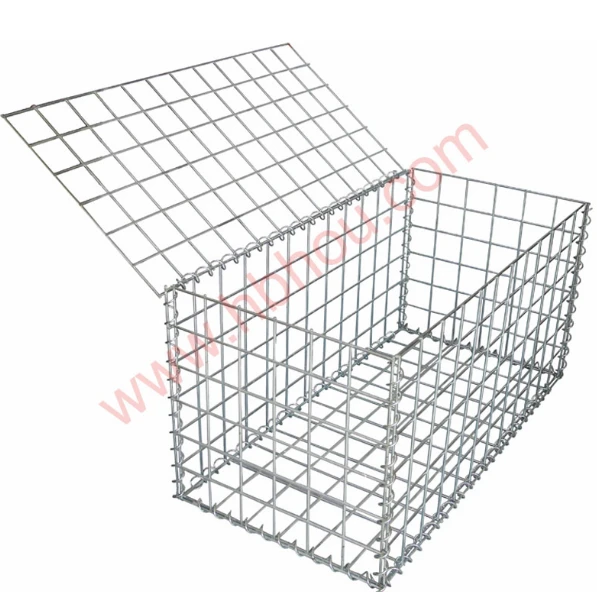

Green Double Door Live Wild Animal Trap Cage: Technical Highlights

- Double-Door Smart Design: Higher catch rate for agile animals (raccoons, feral cats); both-way access reduces escape risk.

- Material Superiority: 3.5mm galvanized Q235 wire, thick PVC coat (0.3mm), resistance to acid rain and animal scratching.

- Safety-Lock System: Patented spring-and-latch, anti-interference under heavy wind or field movement (lab tested to 200N static load).

- Industrial Certifications: ISO 9001 quality, RoHS environmental compliance.

- Extended Service Life: Field trials show working life 4–7 years without visible rust (refer to corrosion line chart above).

- CNC Machined Components: Door mechanism parts for repeatability & smooth operation even in subzero environments.

- Wide Application: Suits animal management in oil & gas depots, waste management stations, waterworks, metallurgical areas, as well as municipal parks.

- Easy Maintenance: Washable with high-pressure water; all parts modular & replaceable.

Manufacturers’ Comparison: Who Leads the Field?

| Supplier | Production Capacity | Customization | Global Export | Key Certificates | Warranty | Relative Cost |

|---|---|---|---|---|---|---|

| HB Hou Group | 80,000 pcs/year | OEM/ODM; custom size/branding | Asia, EU, NA | ISO 9001, RoHS | 3 years | Moderate |

| SafeGuard | 55,000 pcs/year | OEM | NA, LATAM | EPA, ANSI | 2 years | High |

| Wildwise Ltd | 35,000 pcs/year | Partial (logo) | EU, AU | ISO 14001 | 1.5 years | Moderate |

| EZ-Catch Inc. | 42,000 pcs/year | OEM | NA, JP | CE, ANSI | 2 years | High |

Custom Solutions: How HB Hou Elevates Your Project

From heavy duty raccoon live traps for wildlife relocation, to industrial-grade customizable cages for power plants, HB Hou offers design flexibility:

- Mesh size & door style tailored for target animals (rabbits, foxes, cats, etc.)

- Logo branding, powder-coating in corporate colors

- Anti-tamper lock upgrades & sensor integration (optional)

- Packaging to meet ISTA or MIL-STD-810 transit standards

- Multi-language user manuals & on-site installation guidance

Case Studies: Heavy Duty Live Traps in Action

Application: Oilfield Environmental Protection

Challenge: Frequent intrusion by raccoons near oil tanks—a risk to operations and wildlife.

Solution: 120 units of Green Double Door Live Wild Animal Trap Cage deployed with additional anti-slip base. Each unit provided annual field service after installation.

Result: Incident rate decreased by 81%; average capture-to-release cycle down to 1.8 days. ISO 14001 compliance confirmed.

Application: Urban Park & Zoo Management

Scenario: Controlling feral cat population without harming park ecology.

Solution: Custom 2-door traps, with softer inner lining and logo marking. Traps supported both record-keeping and safe animal relocation.

Feedback: Traps remained rust-free after 3 years’ outdoor deployment, with no reported injury to captured animals. Clearance & audit passed local animal welfare review.

Frequently Asked Questions: Professional Guide

1. What distinguishes heavy duty live traps from general-purpose animal cages?

Heavy duty live traps feature reinforced frame welds (usually >3.5mm wire), double-entry triggers, and industrial coatings for resistance against deformation, rust, and repeated animal impact. Designed for professional use under harsh field conditions.

2. Which materials are optimal, and why is galvanized steel a benchmark?

Galvanized steel and powder-coated Q235 offer superior corrosion resistance, mechanical strength, and cost efficiency. Stainless 304 is premium for salt-rich or highly acidic environments but increases cost.

3. What international standards do heavy duty live animal cage traps align to?

Common standards include ISO 9001:2015 (quality), ANSI Z245.60 (safety), and RoHS (environmental). Salt spray resistance follows ASTM B117.

4. How does door mechanism choice affect capture results?

Double-door designs increase catch probability for elusive mammals (like raccoons, skunks); spring triggers ensure rapid closure, preventing escapes—see our data in the table above.

5. What is the typical lifespan of heavy duty live animal traps?

4–7 years in continuous field use is typical for high-end cages, provided proper cleaning and maintenance. Lower-end units may rust or deform after 18–24 months.

6. Are these traps suitable for industrial pipeline areas or only residential?

Yes. With added anti-impact bases, ground anchors, and optional device tracking, these cages work in high-risk industrial zones (refineries, substations, fleets). Many industry clients report successful usage.

7. What’s involved in certification or regulatory approval?

For export to US/EU, proof of ISO 9001, RoHS conformity, and passing EPA wildlife device tests may be required for commercial/municipal use. Please verify with local authorities.

Delivery Schedule, Warranty, and Service Commitment

- Standard Dispatch: 7–14 working days for stock models (up to 500 pcs)

- Custom Orders: 18–28 working days depending on specifications

- Warranty: 3 years standard, defect replacement during first 12 months

- Support: 24/7 tech online, multi-language, field engineers in EU/Asia

- After-sales: Video guidance, on-site training upon request, part replacements shipped in 48hrs

Conclusion: Why Choose Heavy Duty Live Traps by HB Hou?

With its advanced material selection, certified manufacturing process, and outstanding field performance, the Green Double Door Live Wild Animal Trap Cage stands out as a leader in the heavy duty live animal traps market. Whether your need leans toward municipal, agricultural, or industrial animal management, partnering with knowledgeable, certified manufacturers assures not just compliance but operational excellence and long-term value.

Harness the best in heavy duty live traps technology—visit the product page for details or a personalized quote.

[1] "Humane Trapping Market Forecast 2024–2028", Statista.

[2] Industry best practices: WildlifeControlSupplies.com Forum

[3] "Field Verification of Live Trap Effectiveness." Journal of Wildlife Management, 2022. Read online

[4] ISO 9001:2015. iso.org

[5] Product technical specifications: HB Hou Official Website