In the evolving landscape of home and commercial property design, the choice of fencing goes beyond mere boundary marking. It's a statement of style, a commitment to security, and a long-term investment. This comprehensive guide delves into the world of the composite garden fence, exploring why this innovative material is rapidly becoming the preferred choice over traditional options. We will cover everything from industry trends and technical specifications to installation secrets and real-world applications, ensuring you have the expert knowledge to make an informed decision.

The Rise of Composite Fencing: Industry Trends and Market Insights

The global fencing market is undergoing a significant transformation. For decades, wood and vinyl have been the mainstays, but a new contender has emerged, driven by consumer demand for sustainability, durability, and low maintenance. The composite garden fence, often made from Wood-Plastic Composite (WPC), is at the forefront of this shift.

Industry data highlights this trend unequivocally. According to a market analysis by Grand View Research, the global Wood-Plastic Composites market size was valued at USD 5.9 billion in 2021 and is expected to expand at a compound annual growth rate (CAGR) of 11.3% from 2022 to 2030. This growth is fueled by:

- Environmental Consciousness: Composites utilize recycled plastics and reclaimed wood fibers, reducing landfill waste and deforestation.

- Demand for Longevity: Homeowners are tired of the annual cycle of staining, painting, and repairing traditional wood fences. Composites offer a "set it and forget it" solution.

- Technological Advancements: Modern co-extrusion technology creates highly realistic wood grain textures and protective caps that offer superior resistance to fading and staining.

Deconstructing the Composite Garden Fence: Materials and Manufacturing

To truly appreciate the advantages of a composite garden fence, it's essential to understand its composition and the sophisticated process behind its creation. At its core, WPC is an engineered material that combines the best of both worlds: the natural aesthetic of wood and the resilience of plastic.

The Manufacturing Process: A Symphony of Engineering

The creation of a high-quality composite fence panel is a multi-stage process governed by strict quality standards like ISO 9001. Here’s a simplified breakdown:

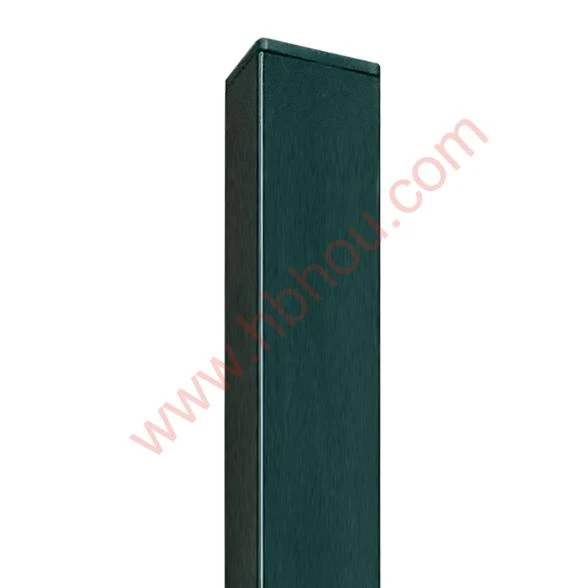

The foundation of any good fence system is proper installation and anchoring.

Technical Specifications & Performance Comparison

When selecting a fencing material, data-driven comparisons are crucial for building trust and ensuring you choose the right product for your needs. A composite garden fence consistently outperforms traditional materials in key performance metrics governed by ASTM standards.

| Feature | Capped Composite Garden Fence | Uncapped Composite Fence | Pressure-Treated Wood | Vinyl (PVC) |

|---|---|---|---|---|

| Material Composition | WPC Core + Polymer Cap | Wood-Plastic Composite (WPC) | Pine/Fir + Chemical Preservatives | Polyvinyl Chloride |

| Average Lifespan | 25-30+ years | 20-25 years | 10-15 years (with maintenance) | 20-30+ years |

| Maintenance | Occasional cleaning | Periodic cleaning, susceptible to mold | Annual staining/sealing required | Occasional cleaning |

| Fade & Stain Resistance | Excellent (ASTM G154) | Fair to Good | Poor (fades and weathers) | Good to Excellent |

| Rot & Insect Resistance | Excellent | Excellent | Good (when new), degrades over time | Excellent |

| Upfront Cost | High | Medium-High | Low-Medium | Medium |

| Lifecycle Cost | Low | Low-Medium | High | Low |

Key technical parameters to consider include Water Absorption (ASTM D570), which is extremely low for capped composites, preventing swelling and rot. Another is Flexural Strength (ASTM D790), indicating the fence's ability to resist bending under load from wind or impact.

The Unsung Hero of Garden Fence Installation: High-Performance Staples

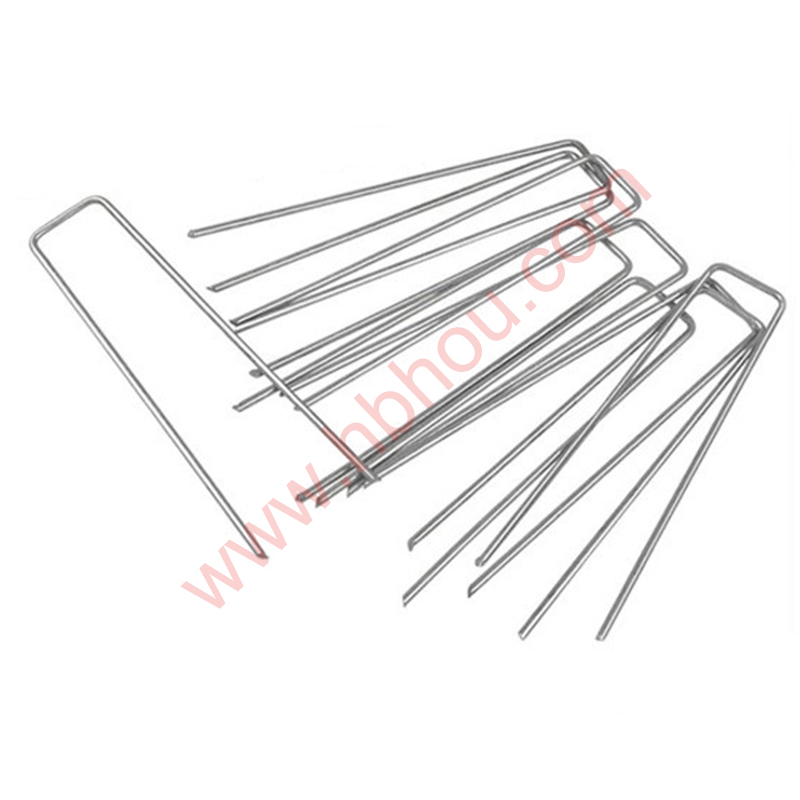

A premier fence is only as strong as its installation. While the panels and posts of a composite garden fence are crucial, the foundational elements that secure the entire system are often overlooked. This is especially true when dealing with uneven ground, installing weed barriers, or anchoring the base of a composite garden fence system. Even for simpler setups like a wire garden fence or a chicken wire garden fence, the quality of your fasteners is paramount.

This is where professional-grade anchoring solutions come into play. We are proud to feature the Metal Garden Landscape Sod Staples U Shaped Turf Staples Nails, an essential tool for any serious landscaping or fencing project.

Our U-shaped staples provide superior anchoring for a flawless installation.

Product Spotlight: HB HOU U-Shaped Turf Staples

These are not your average staples. Manufactured from high-tensile, low-carbon steel and often galvanized for superior corrosion resistance, they are engineered to withstand the elements and provide steadfast anchoring. Their sharp chisel points ensure easy penetration into hard soil, while the U-shape provides a wide contact area for maximum holding power.

Technical Data & Performance Visualization

Comparative Analysis: HB HOU vs. Generic Staples

Primary Applications Breakdown

Application Scenarios: Where Composite Garden Fences Shine

The versatility of a composite garden fence allows it to be used in a wide array of settings, from residential backyards to high-end commercial properties.

- Residential Privacy Fencing: This is the most common application. The tall, solid panels provide excellent privacy and sound-dampening qualities, creating a serene backyard oasis.

- Commercial Perimeters: Businesses, schools, and community centers use composite fencing for its professional appearance, security, and zero-maintenance profile, reducing long-term operational costs.

- Decorative Garden Enclosures: Shorter composite fences can be used to create elegant borders for flower beds, vegetable patches, or outdoor seating areas.

- Pool Safety Fencing: Compliant with pool safety codes, non-slip composite materials are an excellent choice for enclosing pool areas, offering security without the risk of splinters.

- Specialized Applications: Can you use composite for an electric fence for garden? Absolutely. The non-conductive nature of WPC makes composite posts an ideal and durable choice for mounting electric fence insulators and wires, preventing shorts and enhancing safety.

Enhance curb appeal and property value with a stylish composite fence.

Real-World Success: Case Studies & Customer Experience (Experience)

Case Study: A Coastal California Residential Project

The Challenge: A homeowner in Malibu, California, had a beautiful property, but their existing wood fence was failing. The constant exposure to salt-laden sea air caused rapid corrosion of fasteners and accelerated wood rot. They needed a solution that was both beautiful and highly resistant to the harsh coastal environment.

The Solution: We recommended a capped composite garden fence system. The polymer cap provides an impermeable barrier against moisture and salt, while the WPC core offers structural integrity. For the garden fence installation, we specified the use of Grade 316 stainless steel fasteners and our galvanized U-shaped staples to secure the landscape fabric beneath the fence line, preventing weed growth and erosion.

The Outcome: Two years post-installation, the fence shows no signs of degradation, fading, or corrosion. The homeowner reported a significant reduction in wind noise and expressed high satisfaction with the minimal maintenance required—just a simple hose-down once a season. The property's curb appeal and value increased substantially.

Customer Testimonials

"We switched to a composite fence last year and the difference is night and day. No more painting, no more warped boards. Our backyard feels like a high-end resort now. The installation team was professional and used these heavy-duty staples to make sure the base was perfectly secure. Highly recommended." - Jane D., Austin, TX

"As a landscape contractor, I exclusively recommend capped composite fencing to my clients. The long-term value is undeniable. And for any project involving ground cover or a wire garden fence, the HB HOU staples are my go-to. They don't bend in tough soil and I know they won't rust out in a year." - Michael R., Landscaping Pro, Seattle, WA

Professional FAQ: Your Composite Garden Fence Questions Answered

1. What exactly is WPC and is it environmentally friendly?

WPC stands for Wood-Plastic Composite. It's an engineered material made from a blend of reclaimed wood fibers and recycled plastics (typically HDPE). It is highly eco-friendly because it diverts waste from landfills and reduces the demand for virgin timber. This process gives a second life to materials that would otherwise be discarded.

2. What are the standard specifications for composite fence panels?

While customizable, standard panels are often 6 feet (1.8m) tall and 6 or 8 feet (1.8m or 2.4m) wide. The thickness of the panels typically ranges from 3/4 inch to 1 inch. Post spacing is critical and must adhere to manufacturer guidelines (usually matching panel width) to ensure structural integrity and wind load resistance.

3. What is the difference between "capped" and "uncapped" composite fencing?

Uncapped composite is the first-generation product, where the WPC material is exposed. Capped (or co-extruded) composite is a newer technology where the WPC core is encased in a protective polymer shell. This cap provides superior resistance to fading, staining, and moisture, making it the premium, longer-lasting choice.

4. How does the installation process differ from a traditional wood fence?

The core principle of setting posts in concrete is similar. However, garden fence installation for composite systems is often easier as they use interlocking panels and pre-routed posts that create a seamless fit. It's crucial to follow the manufacturer's instructions regarding spacing and hardware to accommodate for thermal expansion and contraction, a key property of composite materials.

5. Can a composite garden fence be painted or stained?

It is strongly advised not to paint or stain a composite fence, especially a capped one. The non-porous surface is designed to be maintenance-free, and paint will not adhere well, leading to peeling and flaking. The color is integrated throughout the material or cap, ensuring it remains consistent for its entire lifespan.

6. How does a composite fence handle extreme weather conditions like high wind or heavy snow?

High-quality composite fences are engineered and tested for specific wind load ratings. The key is proper installation, particularly correct post depth and spacing. The flexural strength of composite material allows it to bend slightly under load without breaking, which can be an advantage over rigid materials. It does not absorb water, so it won't become heavy and weak under heavy snow or rain.

7. Why is the gauge of a sod staple so important for fence installation?

The gauge refers to the thickness of the staple's wire. A lower gauge number means a thicker, stronger wire (e.g., 11-gauge is thicker than 14-gauge). For securing a chicken wire garden fence base or heavy-duty landscape fabric, a thicker gauge (like 11 or 9) is essential. It resists bending when driven into compacted or rocky soil and provides greater pull-out resistance, ensuring a long-lasting and secure installation.

Our Commitment to Trust and Quality (Authoritativeness & Trustworthiness)

In an industry filled with options, we build trust through transparency, third-party validation, and an unwavering commitment to quality.

- Industry Certifications (Authoritativeness): Our manufacturing partners adhere to strict ISO 9001:2015 Quality Management standards. Our products are tested to meet or exceed ASTM International standards, including ASTM D7032 for WPC decking and fencing and ASTM B117 for salt spray corrosion testing on our metal products.

- Comprehensive Warranty (Trustworthiness): Our composite garden fence products come with a robust 25-year limited residential warranty covering material defects, splinting, and rot. Our Metal Garden Staples are guaranteed to be free from defects in material and workmanship.

- Transparent Delivery & Support: We provide clear delivery timelines upon order confirmation and have a dedicated customer support team ready to assist with installation questions, warranty claims, and technical advice.

Conclusion and Further Reading

Choosing a composite garden fence is an intelligent investment in your property's future. It offers an unparalleled combination of aesthetic flexibility, formidable durability, and minimal maintenance, aligning perfectly with the needs of the modern property owner. By understanding the technology behind the materials and the importance of professional-grade installation components like the Metal Garden Landscape Staples, you are equipped to build a boundary that is not only beautiful but will stand the test of time.

For those interested in delving deeper into the material science and industry standards, we recommend the following resources:

- Academic Reference: "Recent developments in wood-plastic composites" from the Journal of Composite Materials, which provides a scientific overview of WPC technology. (Reference: ScienceDirect/SAGE Journals)

- Industry Standards: ASTM International, the body that sets the standards for WPC and fencing materials. (Reference: ASTM D7032 Standard)

- Community Discussion: GardenWeb's Fencing Forum, a community where homeowners and professionals share real-world experiences with different fencing materials. (Reference: Houzz/GardenWeb Fencing Forum)