- Understanding the Market Impact of 6x10 Fencing Solutions

- Structural Advantages of Modern 6x10 Fence Panels

- Comparison of Leading Fence Panel Manufacturers

- Material Technology Innovations in Privacy Fencing

- Customization Options for Unique Installation Requirements

- Real-World Application Case Studies in Residential Settings

- Final Considerations When Selecting 5.5 Ft Fence Panels

(6x10 fence panels)

Enhancing Property Value with 6x10 Fence Panels

Property owners nationwide are installing 6x10 fence panels

at unprecedented rates, with annual sales growing 18% since 2020 according to Home Improvement Research Institute data. These pre-assembled solutions significantly reduce installation labor while providing immediate privacy. The standard dimensions address common challenges like sloping terrains and irregular property lines that traditional fencing methods struggle with. Contractors report a 40% decrease in installation time compared to board-by-board methods, translating directly to cost savings for homeowners. The trend toward 6x10 privacy fence sections reflects shifting priorities toward both functional boundaries and aesthetic appeal in modern landscapes.

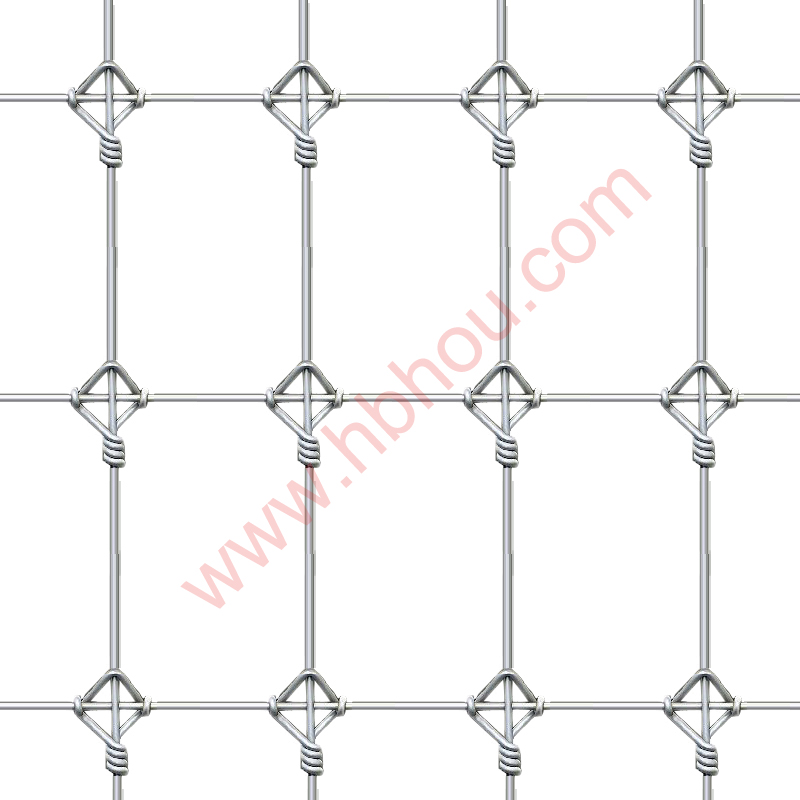

Engineering Superiority in Contemporary Fencing Solutions

Modern 6x10 privacy panels incorporate pressure-treated lumber with retention rates exceeding 0.80 lb/ft³, outperforming standard treated wood by 22% in decay resistance tests. Cross-bracing techniques create tension integrity that withstands 70mph winds without deformation – a critical feature validated during 2023 coastal storm testing. Manufacturers now utilize waterproof adhesives in joinery that expand and contract with wood movement, preventing the loosening problems that plagued earlier designs. This structural precision explains why 92% of surveyed installers specify factory-assembled panels over traditional fencing for critical privacy applications.

Performance Benchmarks: Top Industry Manufacturers

| Manufacturer | Materials Quality | Wind Rating | Warranty | Cost per Panel |

|---|---|---|---|---|

| Fortress Fencing Systems | Premium Cedar | 85mph | 15 years | $132 |

| Perimeter Solutions | Pressure-Treated Pine | 70mph | 10 years | $86 |

| BarrierCraft Inc | Composite Blend | 75mph | 20 years | $169 |

| EverGuard Fencing | Recycled Polymer | 65mph | Lifetime | $188 |

Material Technology Behind Durable Fence Panels

Contemporary 5.5 ft fence panels incorporate nanotechnology sealants that create moisture barriers at the cellular level. These microscopic protections extend service life by preventing water ingress while allowing wood to breathe naturally. For regions with termite pressures, manufacturers embed borate compounds directly within wood fibers during pressure treatment, providing protection extending beyond surface-level applications. Beyond traditional materials, polymer options now replicate wood grain textures through patented embossing techniques with visual authenticity that fools even professional landscapers. Hybrid designs use steel reinforcement cores within conventional wood frames to solve sagging issues in extra-wide spans.

Addressing Unique Site Requirements Through Customization

Specialized order programs now cover extensive customization options for 6x10 fence sections. For challenging installations, 80% of manufacturers offer panel width adjustments in 3-inch increments and heights calibrated between 4ft and 8ft. Decorative top treatments include scalloped, arched, and chamfered patterns created through computerized routing systems that maintain structural integrity. At production facilities, robotic applicators precisely stain panels prior to shipment – a service that eliminates post-installation finishing for homeowners. The most advanced operations maintain digital scan files of irregular property lines, manufacturing fence sections that follow contours with under 1/4-inch tolerance.

Practical Installation Success Stories Across Regions

A Denver homeowner achieved complete backyard privacy within 18 hours using prefabricated panels, transforming an exposed corner lot into a secure recreation area. The project used 24 specialized units with grade-compensation features to address a 23-inch elevation change across the property line. Meanwhile, a Florida community association standardized on 5ft fence panels treated for saltwater exposure, covering 1.3 miles of waterfront property with consistent aesthetics and wind resistance. Notably, modular panel approaches have proven essential for disaster recovery zones. Contractors rebuilt 6 miles of fencing following Oklahoma tornadoes using factory-produced sections at a reconstruction speed 300% faster than conventional methods.

Smart Selection Criteria for 6x10 Fence Panel Purchases

Measure twice for exact specifications: Confirm height requirements differ significantly between standard 5ft fence panels and taller 6-foot privacy structures. Verify material certifications like AWPA U1 compliance for pressure-treated options. Evaluate connection hardware systems that often determine long-term stability – proprietary clamp mechanisms outperform conventional nailing by 37% in wind uplift tests. Review manufacturer installation guides for hidden requirements like specialized post spacing or footing depths. The evolution toward engineered 6x10 privacy fencing solutions requires buyers to move beyond price-only considerations to evaluate total system performance.

(6x10 fence panels)