The Versatility and Applications of 1% 202% X 1 Welded Wire

Welded wire has long been a staple in various industries due to its durability, versatility, and structural integrity. Among the various specifications, the 1% 202% X 1 welded wire stands out for its unique properties and applications. This article delves into the characteristics of this specific welded wire and explores its various uses across different sectors.

Understanding 1% 202% X 1 Welded Wire

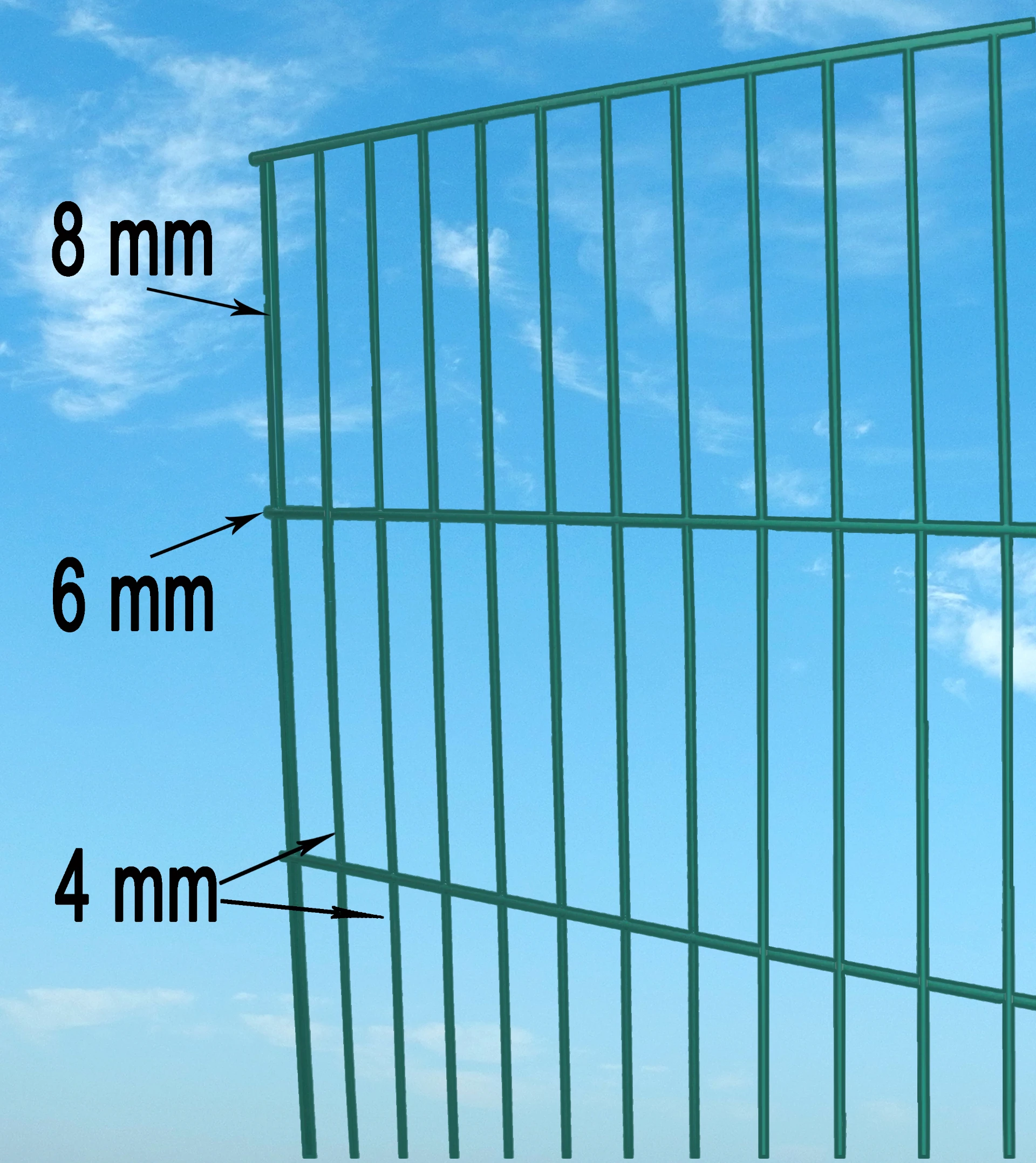

The designation 1% 202% X 1 refers to specific dimensions and properties of the welded wire. Typically, this notation indicates the gauge, spacing, and material composition used in the production of the wire. The 1% often refers to the weight or tensile strength of the wire, indicating it has a robust construction that can withstand considerable pressure and daily wear.

Welded wire is produced by fusing together various strands of wire, which are arranged in a grid-like pattern. This method not only ensures high tensile strength but also provides uniformity in dimensions and spacing. This consistency is critical in applications where precision and structural integrity are paramount.

Key Properties

1. Strength and Durability The welded construction provides enhanced strength compared to traditional fencing or wire products. This makes 1% 202% X 1 welded wire ideal for applications that demand reliability under tension.

2. Corrosion Resistance Many variants of this welded wire are treated to resist rust and corrosion, extending their lifespan significantly, especially in outdoor or harsh environments.

3. Versatile Applications Due to its robust characteristics, this welded wire can be employed in a multitude of industries, from agricultural fencing to construction and industrial applications.

4. Customizable Designs The welded wire can be manufactured in various dimensions and configurations, allowing customization to meet specific project requirements.

Applications of 1% 202% X 1 Welded Wire

1 2 x 1 welded wire

1. Agricultural Fencing Farmers and ranchers widely use welded wire for fencing livestock. Its strength keeps animals contained while also ensuring that predators remain at bay. The grid structure allows visibility, facilitating monitoring of livestock.

2. Construction and Reinforcement In construction, this wire is used in concrete reinforcement, where it provides structural integrity to slabs, walls, and pavements. Its ability to bear heavy loads makes it crucial in the building industry.

3. Garden and Landscape Projects 1% 202% X 1 welded wire can also be utilized in gardening. Homeowners employ it to create trellises for climbing plants or to enclose garden beds, protecting them from pests while allowing for light and air circulation.

4. Industrial Uses Various industrial sectors utilize welded wire in machinery and equipment. For instance, it can be molded into guardrails or safety enclosures, ensuring that machinery operates safely.

5. Architectural Projects With a modern aesthetic, this welded wire is increasingly being used in architectural designs, such as railings, screens, and decorative elements.

6. Manufacturing and Logistics In warehouses and manufacturing plants, it serves as shelving and storage solutions due to its lightweight yet durable nature, maximizing space efficiency.

Maintaining Welded Wire

To extend the lifespan of 1% 202% X 1 welded wire, proper maintenance is essential. Regular inspections can prevent issues related to rust and corrosion. For outdoor applications, periodic cleaning and treatment with protective coatings can enhance longevity. Additionally, ensuring that the wire is properly tensioned and secured can prevent sagging and damage over time.

Conclusion

1% 202% X 1 welded wire exemplifies the blend of durability, versatility, and aesthetic appeal that makes it a preferred choice across various industries. Whether for agricultural, architectural, or industrial applications, its robust characteristics ensure that it will stand the test of time. As industries continue to evolve, the demand for high-quality welded wire is likely to remain steadfast, showcasing the enduring value and utility of this essential material. With continued innovation and adaptation, welded wire will undoubtedly play a crucial role in future projects, reflecting both functionality and design.