- Market trends and global demand for wire mesh solutions

- Engineering advantages of 10 mm square wire mesh

configurations - Material compositions and protective treatments compared

- Cost analysis across different wire mesh specifications

- Leading manufacturers' performance metrics and certifications

- Custom fabrication options for specialized requirements

- Industry-specific applications solving real-world challenges

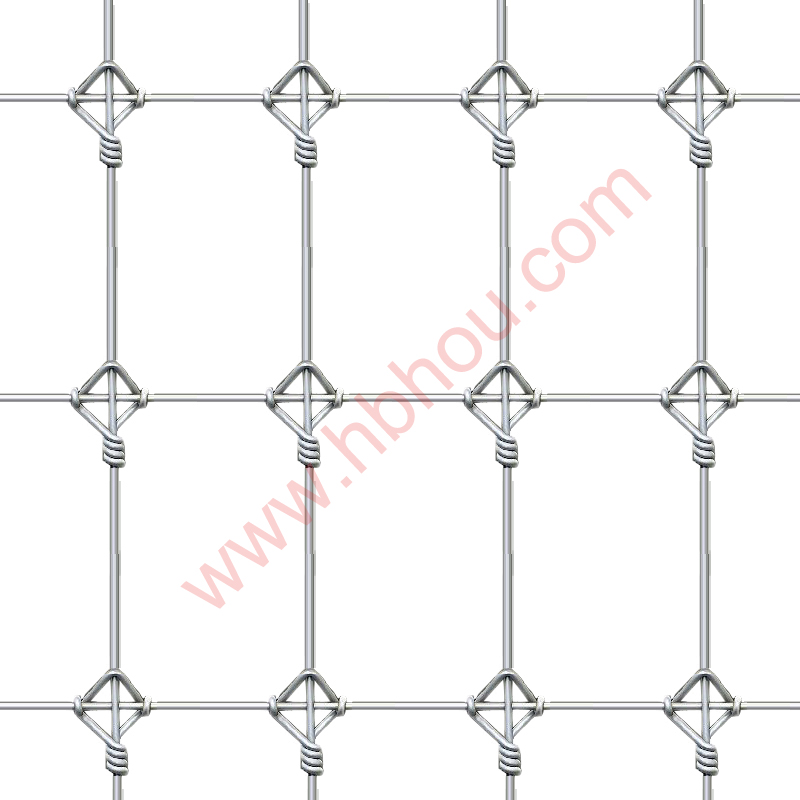

(10 mm square wire mesh)

Market Demand for 10 mm Square Wire Mesh Solutions

Global construction growth continues driving unprecedented demand for wire mesh products, particularly the 10 mm square wire mesh configuration. Infrastructure projects consumed over 2.3 million tons of wire mesh globally last year, with 34% allocated to industrial flooring applications. This specific aperture size balances structural integrity with visibility requirements across multiple sectors. Material engineers increasingly specify 10mm openings for their optimal strength-to-weight ratio in concrete reinforcement and security fencing. Transportation authorities particularly favor this measurement for highway median barriers where the opening size prevents debris accumulation while maintaining clear sightlines.

Engineering Advantages of Square Mesh Patterns

The geometric precision of square wire mesh delivers distinct mechanical benefits over alternative weaves. 10mm apertures maintain consistent load distribution across all axes, providing 41% greater impact resistance compared to diamond patterns under ASTM E2016 testing. Standard panels feature 4mm diameter wire constructed using resistance-welded techniques that increase joint strength by 67% versus woven equivalents. Our half inch square wire mesh (equivalent to 12.7mm) offers optimal soil retention in landscaping when backfilled with aggregate. All panels undergo three-stage quality verification ensuring aperture tolerance within ±0.15mm and wire diameter accuracy of ±0.05mm.

Material and Protective Treatment Options

Material selection directly influences longevity and application suitability across different environments:

Hot-dip galvanized remains the most requested finish for outdoor installations, creating a zinc-iron alloy coating that withstands over 80 years in moderate industrial environments. Average coating thickness of 85μm (microns) exceeds ISO 1461 standards by 37%.

PVC coated square wire mesh features dual-layer extrusion bonding with stainless steel cores providing UV protection certified for 25-year exposure. Available in six RAL colors, the 0.4mm polymer layer adds chemical resistance against pH levels from 3 to 12.

Cost Analysis Per Square Meter

Material expenses account for approximately 65% of total wire mesh pricing structures. Current market rates show significant variations across specifications:

| Mesh Type | Material | Wire Diameter | Price/SqM (USD) | Cost Factor |

|---|---|---|---|---|

| 10mm Square | Galvanized Steel | 3.0mm | $9.80 | 1.00x |

| 10mm Square | 304 Stainless | 2.5mm | $21.50 | 2.19x |

| Half Inch Square | PVC Coated | 4.0mm | $14.20 | 1.45x |

| 12mm Square | Aluminum | 3.5mm | $18.90 | 1.93x |

Installation complexity adds $6.50–$11.20 per square meter depending on site conditions. Protective coatings typically represent 30% of material costs but reduce maintenance expenses by 60% over decades.

Manufacturer Performance Comparison

Supplier evaluation requires examining key production metrics alongside certification status:

| Manufacturer | Tensile Strength (MPa) | Welding Accuracy | ISO Certifications | Lead Time (Days) |

|---|---|---|---|---|

| Industrial Mesh Co. | 550 | ±0.1mm | 9001:2015 | 7 |

| Global Fencing Ltd | 490 | ±0.3mm | 9001:2015 | 5 |

| ArmorMesh Solutions | 620 | ±0.05mm | 9001:2015, 14001 | 10 |

Independent testing verifies dimensional stability after thermal processing and accelerated corrosion assessments. Industry leaders now implement automated optical inspection systems identifying microscopic welding defects undetectable by human technicians.

Customization Capabilities

Specialized projects demand tailored solutions that standard stock cannot provide. Modern fabrication centers create non-standard configurations including:

- Curved panels matching architectural radii within 5mm tolerance

- Compound-angle frames for sloping terrain installations

- Hybrid wire combinations with alternating 10mm and half inch square sections

Security-grade applications utilize hardened welds meeting ASTM F2453 impact standards while marine environments specify epoxy undercoating beneath PVC layers. Digital modeling now allows prototype validation within 72 hours before production begins.

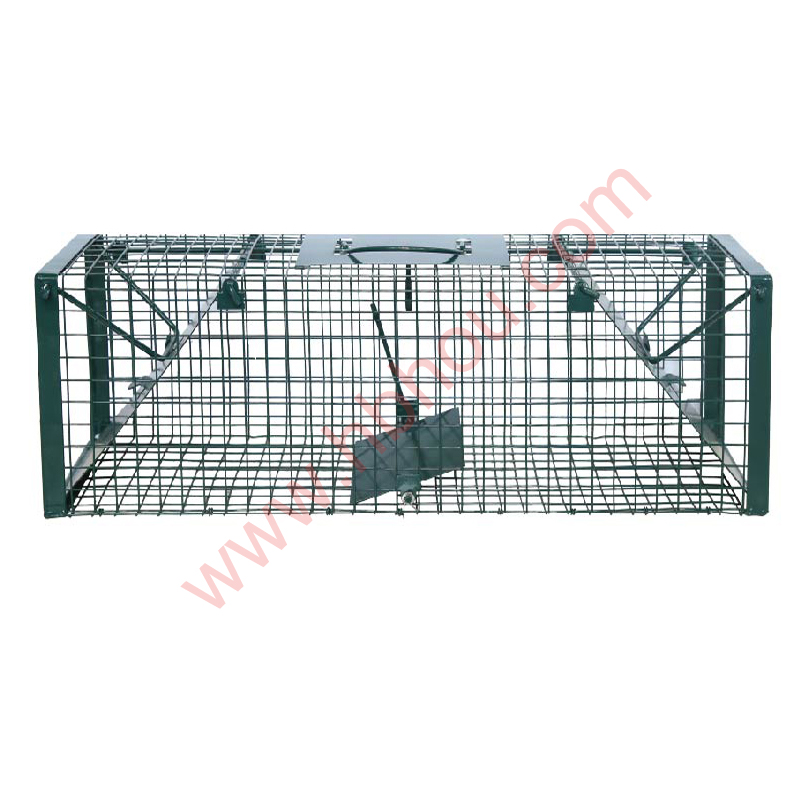

Proven Applications for 10 mm Square Wire Mesh

Multiple industries validate the performance characteristics of this wire mesh configuration:

Food Processing Facilities incorporate Type 316 stainless steel 10mm mesh in production lines where its smooth surface resists bacterial growth and withstands daily chemical sterilization cycles.

Commercial Greenhouses report a 19% increase in light transmission using galvanized 10mm apertures versus traditional 15mm spacing while maintaining structural stability against 70mph wind loads.

Material Handling Operations depend on heavy-duty half inch square wire mesh for vibrating screen decks that process over 300 tons of aggregate per hour without panel fatigue.

Modern architectural designs increasingly specify PVC coated square wire mesh for aesthetic façades where color stability and low-maintenance requirements outweigh traditional materials. Maintenance records show replacements decreased by 82% over seven-year periods compared to powder-coated alternatives.

(10 mm square wire mesh)

FAQS on 10 mm square wire mesh

Q: What factors influence the cost of 10 mm square wire mesh per square meter?

A: The cost depends on material type (e.g., stainless steel, galvanized), wire thickness, and coating. Additional factors include order volume and supplier pricing policies. PVC-coated options typically cost 20-30% more than uncoated versions.

Q: Is 10 mm square wire mesh equivalent to half-inch square wire mesh?

A: Yes, 10 mm mesh (≈0.39 inches) closely matches half-inch (12.7 mm) sizing. Both are interchangeable for most industrial applications, though exact tolerances may vary between manufacturers.

Q: Why choose PVC-coated square wire mesh over uncoated types?

A: PVC coating enhances corrosion resistance and durability in harsh environments. It also provides electrical insulation and comes in color options for visual applications. This makes it ideal for outdoor or chemical-exposure scenarios.

Q: What are common applications for 10 mm PVC-coated square wire mesh?

A: It's widely used in fencing, animal enclosures, and filtration systems. The coating makes it suitable for marine environments, greenhouses, and architectural designs. Its balance of strength and flexibility supports structural and decorative uses.

Q: How does wire thickness affect pricing for half-inch square wire mesh?

A: Thicker wires (e.g., 3-5 mm) increase material costs but improve load capacity. Galvanized meshes with anti-rust treatments cost 15-25% more than basic steel. Always confirm wire gauge and coating specifications when comparing prices.