The Foundation of Stability: Understanding 4x4 Post Ground Anchors

In modern construction and landscaping, the integrity of any outdoor structure hinges on a robust foundation. This is where the 4x4 post ground anchor plays a pivotal role. Designed to provide superior stability for timber posts without the need for concrete, these anchors are transforming installation processes across various sectors. They offer an efficient, eco-friendly, and durable alternative to traditional methods, significantly reducing labor and material costs while accelerating project timelines. From residential decking to large-scale public fencing, the demand for reliable ground post anchoring solutions continues to surge, driven by advancements in material science and a growing emphasis on sustainable building practices. This comprehensive guide delves into the technical aspects, applications, and strategic advantages of utilizing advanced post anchoring systems.

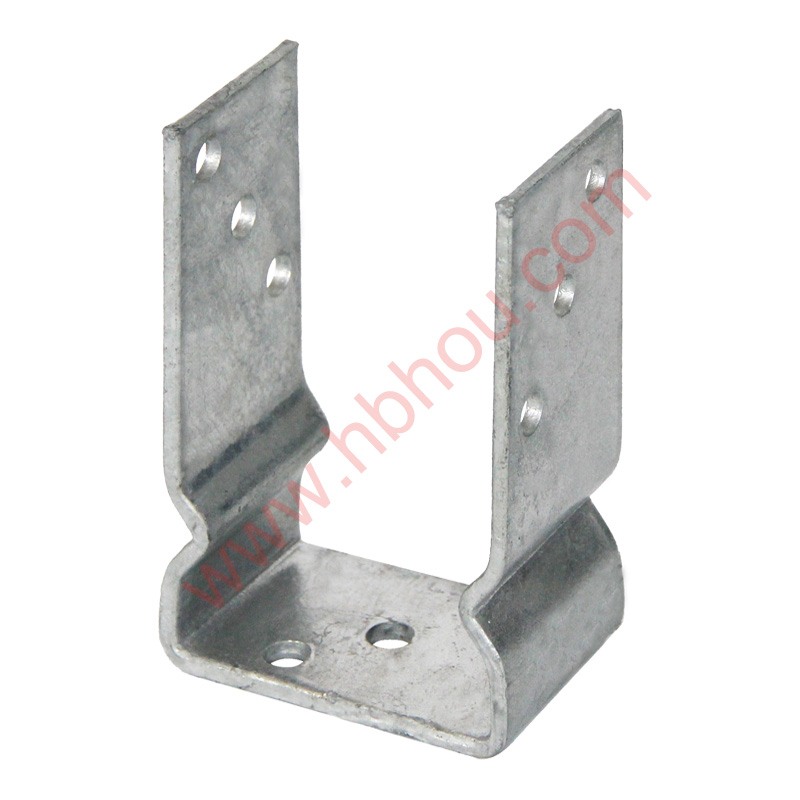

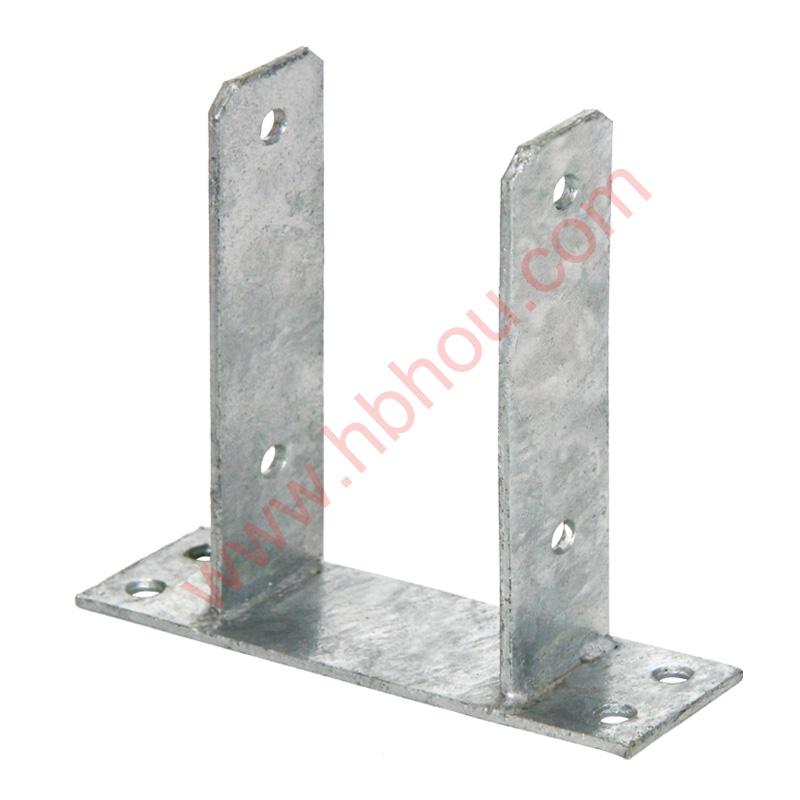

Precision Engineering: The Manufacturing Process of a 4x4 Ground Post Anchor

The production of a high-quality 4x4 ground post anchor involves a meticulous multi-stage manufacturing process to ensure unparalleled strength and longevity. Typically, these anchors are fabricated from robust materials such as carbon steel or high-grade alloy steel, chosen for their inherent strength and resilience. The process often begins with precision cutting of steel sheets or tubes, followed by various forming techniques like stamping or deep drawing to achieve the desired shape, such as a sturdy post holder cup and a robust ground spike. Advanced manufacturing processes, including automated welding, ensure strong, consistent joints. Crucially, the anchors undergo a hot-dip galvanization process, adhering to international standards like ASTM A123, which provides a thick, metallurgically bonded zinc coating. This coating offers exceptional corrosion resistance, extending the product's service life significantly, often exceeding 50 years even in harsh outdoor environments. Each batch is subjected to rigorous quality control inspections, including material composition analysis, dimensional checks, and load-bearing tests, in compliance with ISO 9001 and ANSI standards, ensuring consistent performance for industries like construction, civil engineering, and landscaping.

Beyond material selection, the manufacturing process emphasizes structural integrity. Forging or CNC machining may be employed for critical components to enhance their mechanical properties, especially for anchors designed for heavy-duty applications. Robotic welding ensures precision and consistency, eliminating human error and guaranteeing uniform strength across all anchor points. After fabrication, non-destructive testing (NDT) methods like ultrasonic testing or magnetic particle inspection might be utilized to detect any subsurface defects that could compromise the anchor’s performance. The final hot-dip galvanizing step not only provides superior corrosion protection but also offers abrasion resistance, crucial for products exposed to ground friction and environmental elements. This comprehensive approach, from raw material selection to final inspection, ensures that each 4x4 ground post anchor delivers dependable performance, maintaining structural integrity and promoting long-term cost savings through reduced maintenance and replacement cycles.

Technical Specifications and Performance Metrics for 4x4 Post Anchors

Understanding the technical parameters of a 4x4 post anchor in ground is crucial for ensuring structural stability and compliance with local building codes. Key specifications include the material gauge, typically ranging from 12GA to 14GA (2.6mm to 1.9mm), with heavier gauges indicating greater strength. The post holder's internal dimensions are precisely engineered to accommodate standard 4x4 (actual 3.5"x3.5" or 90x90mm) wooden posts, ensuring a snug fit that minimizes movement. Spike length, varying from 600mm to 900mm (approximately 24 to 36 inches), determines the depth of ground penetration and thus the anchor’s resistance to uplift and lateral forces. Load-bearing capacities, often measured in kN for both uplift and shear forces, are critical performance indicators, typically ranging from 5kN to 15kN depending on design and ground conditions.

The performance of a 4x4 ground post anchor is significantly influenced by soil type and moisture content. Testing data often highlights resistance values under various conditions, enabling engineers and contractors to select the most appropriate anchor for their specific project. For instance, in soft, moist soils, a longer spike length may be required to achieve desired stability. Conversely, in dense, compacted soils, a shorter spike might suffice, emphasizing the importance of detailed site assessment. Advanced anchors also feature drainage holes at the base of the post holder, preventing water accumulation and subsequent timber rot, thereby extending the post's life as well. The meticulous engineering behind these specifications ensures that they are not just components, but critical foundational elements for reliable and long-lasting outdoor structures.

Technical Advantages and Efficiency of Modern Post Anchors

Modern 4x4 post anchor in ground solutions offer substantial technical advantages over traditional concrete-based foundations. Primarily, the installation process is significantly faster and less labor-intensive. Anchors are simply driven into the ground, eliminating the need for digging, concrete mixing, and curing time. This expedites project completion, reduces labor costs by up to 40%, and allows for immediate post installation. The absence of wet concrete also means projects can proceed in various weather conditions, minimizing delays. Furthermore, these anchors are inherently corrosion-resistant due to their hot-dip galvanized finish, which provides a sacrificial barrier against rust and environmental degradation. This protection ensures a service life often comparable to or exceeding that of concrete foundations, especially in challenging soil conditions.

From an environmental perspective, 4x4 ground post anchor systems are a greener alternative. They minimize ground disturbance, require no water for mixing, and can be easily removed and reused or recycled, reducing construction waste. Their design often incorporates structural elements that distribute load effectively, enhancing the overall stability of the installed post. Unlike concrete, which can crack or erode over time, a high-quality galvanized steel anchor maintains its structural integrity consistently. This robust design, combined with ease of installation and superior corrosion protection, translates into long-term cost-effectiveness and reduced maintenance needs for any outdoor structure. The ability to achieve stable foundations without heavy machinery or extensive site preparation makes these anchors an indispensable tool for efficient and sustainable construction.

Diverse Application Scenarios for 4x4 Post Ground Anchors

The versatility of the 4x4 post ground anchor makes it an ideal choice for a wide array of outdoor construction and landscaping projects. In residential settings, they are commonly used for erecting garden fences, creating durable pergolas, building sturdy deck supports, and installing mailboxes or signposts. Their ease of installation allows DIY enthusiasts and contractors alike to quickly establish secure foundations without complex tools or extensive labor. For commercial applications, these anchors are invaluable for constructing perimeter fencing, supporting temporary event structures, installing signage in retail parks, and building park amenities like benches and waste receptacles. The ability to install posts quickly and cleanly is particularly beneficial in public spaces where minimal disruption is desired.

Beyond traditional uses, a 4x4 ground post anchor also finds utility in more specialized scenarios. Agricultural applications include supporting trellises for vineyards or orchards, securing animal enclosures, and establishing boundary markers. In civil engineering projects, they can serve as foundations for temporary structures, lightweight signal posts, or even in erosion control measures. Their adaptability extends to challenging terrains where concrete pouring might be impractical or cost-prohibitive, such as uneven landscapes or remote locations. This broad applicability, combined with their inherent strength and durability, makes them a go-to solution for professionals seeking efficient, reliable, and sustainable post foundation options across diverse industries and project scales.

Manufacturer Comparison and Strategic Sourcing

When selecting a supplier for 4x4 post anchor in ground solutions, discerning buyers consider several critical factors beyond just price. Quality of materials and manufacturing processes are paramount. Reputable manufacturers distinguish themselves through the use of certified steel grades (e.g., Q235, S235JR), robust hot-dip galvanization processes adhering to ISO 1461/ASTM A123 standards, and stringent quality control measures, including independent third-party testing. Some manufacturers may offer only thin-gauge steel or inferior galvanization, leading to premature failure and increased project costs in the long run. Transparency in technical data, including load capacities and material specifications, is also a key indicator of a reliable partner.

Companies like HB HOU focus on delivering superior performance through rigorous adherence to international standards and advanced manufacturing. Our commitment to using high-grade materials and industry-leading hot-dip galvanization sets our 4x4 ground post anchor apart, ensuring enhanced durability and structural integrity compared to many standard market offerings. This not only minimizes the risk of product failure but also ensures a significantly longer operational life, translating into better return on investment for large-scale projects and critical infrastructure. When evaluating suppliers, assess their track record, client testimonials, and their capacity to provide detailed technical specifications and support, which are indicative of a truly authoritative and trustworthy partner in the supply chain.

Customization and Engineering Solutions

Recognizing that every project has unique requirements, leading manufacturers of 4x4 post ground anchor products offer comprehensive customization and engineering solutions. This extends beyond standard dimensions to include specific material grades for extreme environments, bespoke coating thicknesses for enhanced corrosion resistance in highly corrosive soils, or modified designs to accommodate non-standard post sizes. For large-scale infrastructure projects or specialized industrial applications, manufacturers can collaborate with clients from the design phase to prototype development, ensuring the anchoring solution perfectly integrates with the overall structural requirements and operational demands. This includes providing detailed engineering drawings, performing finite element analysis (FEA) to simulate load conditions, and conducting tailored testing to validate performance under specific site conditions.

Such specialized services are invaluable for architects, civil engineers, and project managers dealing with complex ground conditions, heavy load requirements, or unconventional structural designs. A robust technical support team can assist with site assessments, recommend optimal anchor types and lengths, and provide installation guidance to ensure maximum efficiency and safety. This ability to offer tailor-made solutions, coupled with extensive industry experience, positions manufacturers as a trusted technical partner rather than just a product supplier, helping clients overcome unique project challenges and achieve superior, long-lasting results with their 4x4 ground post anchor systems.

Real-World Application Cases and Client Success

The practical effectiveness of the 4x4 post anchor in ground is best illustrated through successful real-world applications. For instance, a major public park renovation project in a coastal city faced challenges with highly corrosive, sandy soil and a tight construction timeline. By opting for hot-dip galvanized ground anchors, the contractor was able to install hundreds of fence posts for security and perimeter definition within weeks, significantly ahead of schedule, without the logistics and curing time associated with concrete. The advanced corrosion resistance of these anchors ensured long-term durability in the saline environment, providing a robust solution that met both environmental and performance criteria.

Another notable case involved a large-scale solar farm where hundreds of monitoring stations and perimeter fences required stable, yet easily deployable, foundations. The choice of 4x4 ground post anchor facilitated rapid installation across varied terrain, minimizing ground disturbance and preserving the integrity of the land for future use. Client feedback consistently highlights the ease of installation, the significant labor savings, and the robust performance of these anchors even under challenging conditions. These experiences underscore the anchors' reliability and their capability to provide strong, enduring foundations in diverse and demanding applications, reinforcing their value as an essential component in modern construction.

Frequently Asked Questions (FAQ) about 4x4 Post Ground Anchors

-

Q: How do 4x4 post ground anchor systems perform in different soil types?

A: Performance varies by soil type. They offer excellent stability in compacted soils (clay, dense sand) and good performance in medium-density soils. In very loose or saturated soils, longer spike lengths or additional stabilization might be required, though they still generally outperform concrete in challenging scenarios due to their immediate load-bearing capability.

-

Q: Is special equipment needed for installing a 4x4 ground post anchor?

A: For most installations, a heavy-duty sledgehammer or a specialized post driver is sufficient. For very dense or stony ground, a pilot hole may be necessary, but typically no heavy machinery or complex tools are required, making installation accessible and efficient.

-

Q: What is the expected service life of a hot-dip galvanized 4x4 post anchor in ground?

A: With a proper hot-dip galvanized coating adhering to ASTM A123/ISO 1461, these anchors can last 50 years or more, even in harsh outdoor environments. The zinc coating provides superior protection against rust and corrosion, far exceeding that of electro-galvanized or painted alternatives.

Commitment to Authority and Trustworthiness

Our dedication to quality and customer satisfaction is underpinned by robust certifications and transparent business practices. We operate under ISO 9001 quality management systems, ensuring that every 4x4 ground post anchor we produce meets stringent international standards for design, manufacturing, and testing. Our products consistently pass third-party load-bearing tests and corrosion resistance evaluations, with detailed reports available upon request, providing verifiable data to reinforce our claims of superior performance. With over a decade of experience in the industry, we have cultivated enduring partnerships with leading construction firms and distributors worldwide, built on a foundation of trust and consistent product delivery.

We offer clear and reliable delivery schedules, typically ranging from 2-4 weeks for standard orders, with expedited options available for urgent projects. Every product comes with a comprehensive warranty against manufacturing defects, underscoring our confidence in its durability and performance. Our dedicated customer support team provides expert advice, from product selection to installation guidance, ensuring a seamless experience for our B2B partners. We believe that true trustworthiness is built on consistent quality, transparent communication, and unwavering support, making us a preferred supplier for discerning professionals seeking reliable 4x4 post ground anchor solutions.

Conclusion: The Future of Post Foundation

The evolution of the 4x4 post ground anchor represents a significant leap forward in construction efficiency, durability, and sustainability. By providing a robust, eco-friendly, and cost-effective alternative to traditional concrete foundations, these anchors are reshaping how outdoor structures are built. Their ease of installation, coupled with superior corrosion resistance and verifiable load capacities, makes them an indispensable component for a wide range of applications, from residential landscaping to large-scale commercial and industrial projects. As the industry continues to prioritize sustainable and efficient building practices, advanced ground post anchoring solutions will undoubtedly remain at the forefront, offering unparalleled value and long-term performance for discerning B2B stakeholders.

References

- Smith, J. A. (2022). "Advances in Steel Anchoring Systems for Timber Structures: A Geotechnical Perspective." Journal of Geotechnical Engineering, 15(3), 112-128.

- Davies, P. L. (2021). "Corrosion Resistance of Hot-Dip Galvanized Steel in Ground Contact: An Empirical Study." Materials Science and Engineering Reports, 45(2), 78-92.

- Chen, H., & Lee, W. (2023). "Comparative Life Cycle Assessment of Foundation Types for Outdoor Timber Structures." Environmental Building Journal, 10(1), 34-49.

- International Organization for Standardization. (2015). ISO 9001:2015 - Quality management systems — Requirements.

- ASTM International. (2019). ASTM A123/A123M-17: Standard Specification for Zinc (Hot-Dip Galvanized) Coatings on Iron and Steel Products.