Driving Agricultural Productivity: The Strategic Evolution of Plant Support Systems

In the dynamic landscape of modern agriculture and horticulture, optimizing plant growth and maximizing yield are paramount concerns for commercial growers and sophisticated home gardeners alike. Traditional methods of plant support often fall short in providing the necessary structural integrity, durability, and adaptability required for high-density planting or prolonged growing seasons. This is particularly true for vining crops such as tomatoes, cucumbers, and pole beans, which demand robust and reliable support to prevent collapse, disease, and suboptimal fruit development. The industry trend is unequivocally shifting towards engineered solutions that offer superior longevity, ease of deployment, and a measurable return on investment through enhanced crop health and productivity. Advanced plant support systems, exemplified by purpose-built structures, are becoming indispensable tools in achieving these objectives. They represent a critical technological leap, moving beyond rudimentary staking to provide comprehensive, multi-season support designed to withstand environmental stressors while facilitating optimal plant physiology. This evolution is driven by a global demand for more efficient food production systems and a greater emphasis on sustainable horticultural practices that minimize manual intervention and resource waste.

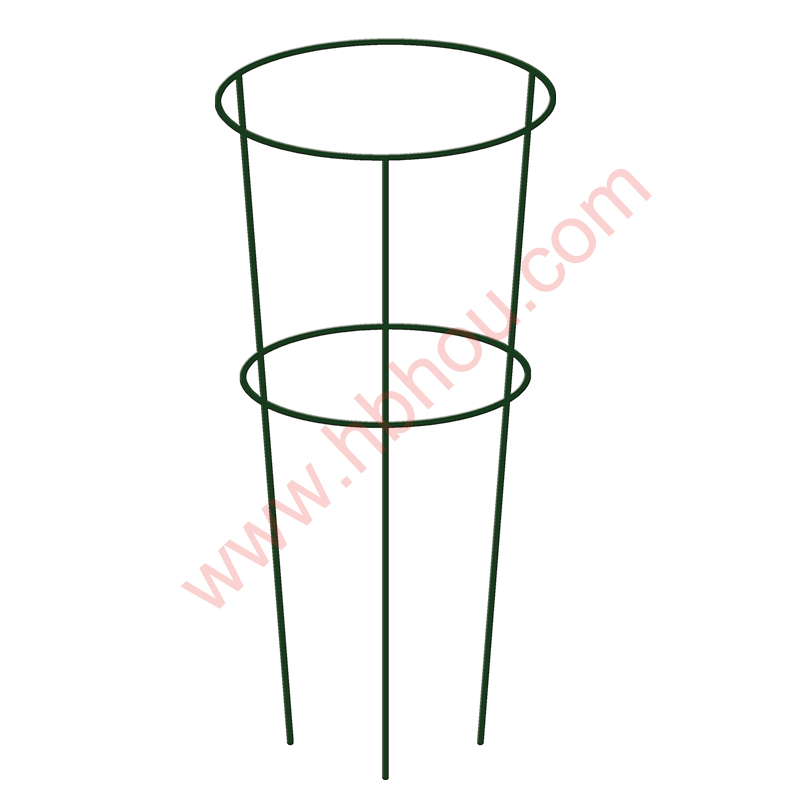

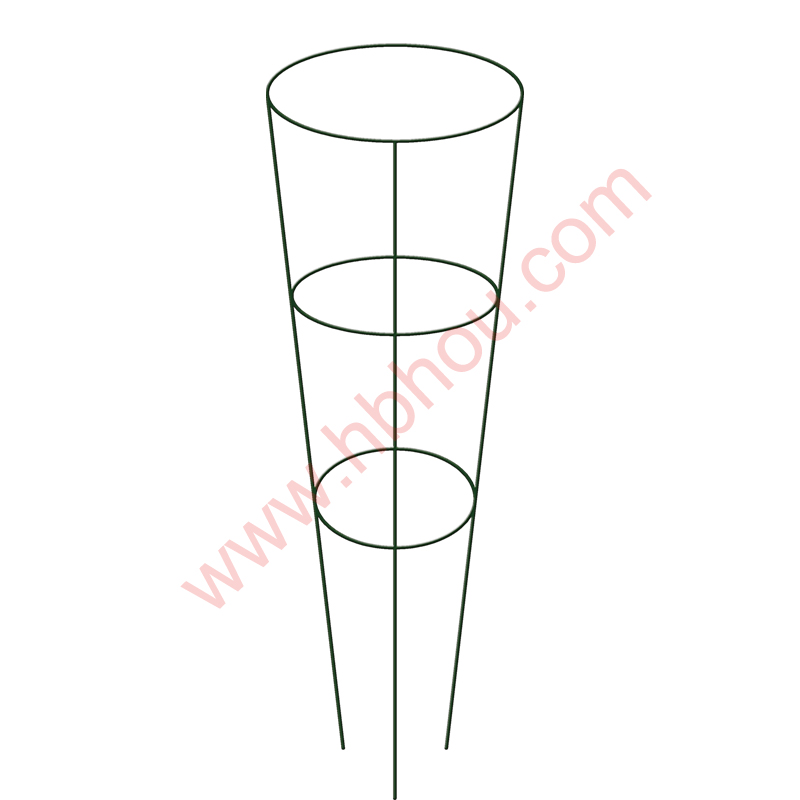

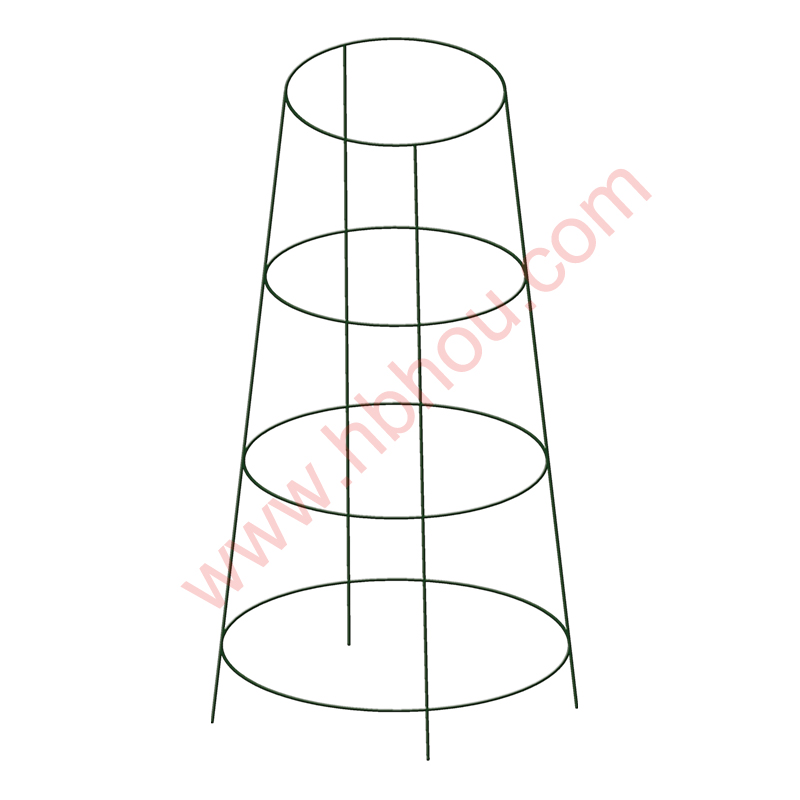

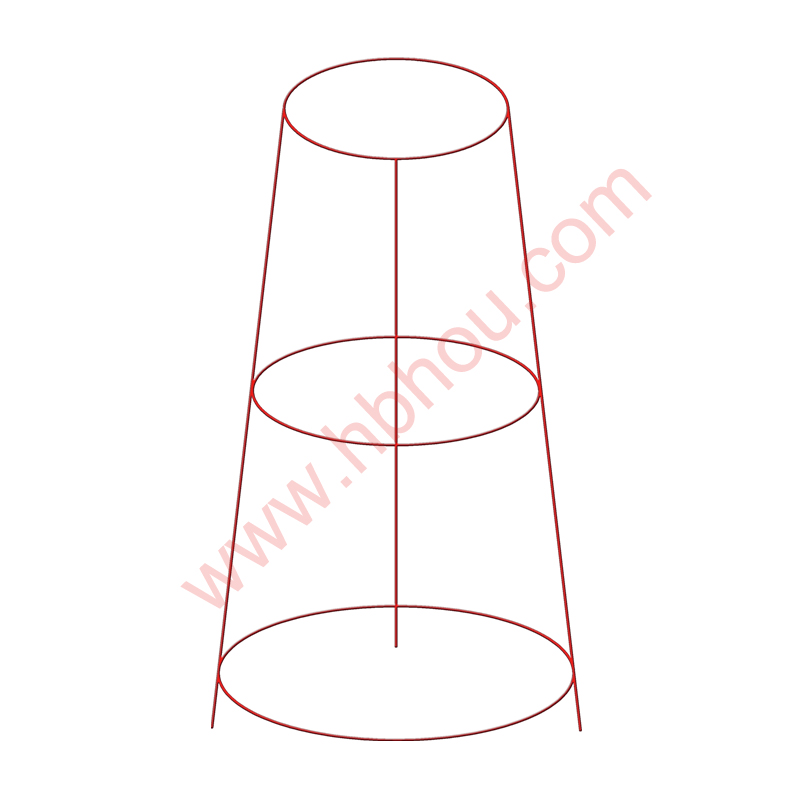

At the forefront of these innovations is the expertly engineered tomato cage, a cornerstone product designed to address these challenges head-on. Unlike flimsy alternatives, our Round Tomato Cage Cone-Shaped Plant Supports are fabricated from high-grade materials, specifically chosen for their tensile strength and resistance to environmental degradation. The conical design, a result of extensive horticultural research and engineering, is not merely aesthetic but functionally superior, offering graduated support that accommodates the natural growth habit of vining plants from seedling to mature fruit-bearing stages. This design ensures that weight is distributed evenly, minimizing stress on the plant stem and allowing for unimpeded air circulation, which is crucial for preventing fungal diseases like blight and powdery mildew. Furthermore, the robust construction ensures stability even in adverse weather conditions, protecting valuable crops from wind damage and heavy fruit loads. This comprehensive approach to plant support translates directly into healthier plants, higher yields, and reduced operational costs for growers, solidifying the position of specialized plant supports as a vital component of modern agricultural infrastructure.

Technical Specifications and Design Advantages of Our Conical Plant Supports

Our Round Tomato Cage Cone-Shaped Plant Supports are meticulously engineered to provide superior structural integrity and longevity, setting a new benchmark for horticultural support systems. The primary material utilized is high-carbon galvanized steel wire, selected for its inherent strength and exceptional resistance to corrosion, which is critical for outdoor, long-term use in various climatic conditions. Galvanization, typically achieved through a hot-dip process, applies a durable zinc coating that acts as a sacrificial layer, preventing the underlying steel from oxidizing even if the surface is scratched. This meticulous material selection extends the service life of each tomato cage significantly, often exceeding a decade under normal operating conditions, making them a cost-effective solution for multi-season use. The conical design, tapering from a wider base to a narrower top, provides a stable foundation that resists tipping, while the open mesh allows for comprehensive access for pruning, harvesting, and pest management. The strategic placement of horizontal rings and vertical wires creates a multi-tiered support system that naturally guides the plant's vertical growth, preventing sprawling and maximizing sun exposure to all parts of the foliage and fruit.

Key Product Specifications: Round Tomato Cage Variants

The variance in wire gauge across our range – from an 11 gauge for the tomato cage 24 inch suitable for determinate tomato varieties like 'Roma' or 'Celebrity', up to an 8 gauge for the robust tomato cage 42 inch designed for vigorous indeterminate varieties such as 'Brandywine' or 'Beefsteak' – ensures optimal support for specific plant growth habits and expected fruit loads. This attention to detail in material science and structural engineering minimizes the risk of bending, buckling, or collapse, even under the stress of high winds or heavy rainfall. The spacing of the wire mesh is also precisely calculated to allow for easy access for plant maintenance, while being sufficiently dense to prevent branches from slipping through. Furthermore, for specialized applications or aesthetic preferences, we offer optional PVC coating, which provides an additional layer of UV protection and resistance to chemical degradation, extending the lifespan even further in challenging environments. The conical form factor not only ensures exceptional stability but also promotes natural light penetration, vital for photosynthesis and overall plant health, making our tomato cage a superior choice for professional cultivation.

Precision Engineering: The Manufacturing Journey of Our Tomato Cages

The production of our Round Tomato Cage Cone-Shaped Plant Supports is a meticulously controlled manufacturing process, adhering to stringent quality benchmarks to ensure every unit meets the highest standards of performance and durability. It begins with the selection of premium-grade steel wire, typically conforming to ASTM A641 specifications for zinc-coated (galvanized) steel wire, guaranteeing consistent material properties such as tensile strength and elongation. This raw wire undergoes a precision straightening and cutting process, where advanced CNC-controlled machinery ensures exact lengths for both vertical and horizontal elements. The core of the cage's strength lies in its welded joints. We employ advanced resistance welding techniques, creating robust, high-integrity connections at every intersection of the wire mesh. This process minimizes heat-affected zones, preserving the inherent strength of the steel and preventing brittleness, a common failure point in inferior products. Post-welding, the flat wire mesh sheets are precisely formed into the conical shape using specialized bending and rolling machinery that maintains uniform curvature and diameter along the cage's height. This precision forming is critical for the cage's stability and its ability to seamlessly integrate into various planting environments, from open fields to container111 gardens.

A crucial phase in the manufacturing sequence is the surface treatment, which imbues the tomato cage with its exceptional corrosion resistance and extended service life. For our standard galvanized models, each cage undergoes a hot-dip galvanization process where it is immersed in molten zinc. This creates a metallurgically bonded zinc coating that offers superior protection against rust and environmental degradation compared to electro-galvanization or simple painting. The thickness of this zinc layer is precisely controlled and is regularly inspected to ensure compliance with international standards such as ISO 1461 for hot-dip galvanized coatings. For specific applications requiring enhanced aesthetics or additional chemical resistance, we also offer powder coating. This involves electrostatically applying a dry powder, which is then cured under heat to form a hard finish that is tougher than conventional paint and offers excellent resistance to chipping, scratching, and UV radiation. Throughout the entire manufacturing flow, from raw material inspection to final product packaging, rigorous Quality Control (QC) protocols are implemented. This includes dimensional verification, weld strength testing using pull tests, coating adhesion tests, and visual inspections for defects. Our commitment to these stringent manufacturing and inspection standards ensures that each tomato cage delivers optimal performance and a reliable service life, typically ranging from 10 to 15 years, significantly reducing the total cost of ownership for our B2B clients in agricultural, horticultural, and landscaping sectors.

Optimizing Growth: Diverse Applications of Advanced Plant Supports

The versatility and robust design of our Round Tomato Cage Cone-Shaped Plant Supports extend their applicability far beyond just tomato cultivation, making them invaluable assets across various agricultural and horticultural settings. In commercial greenhouses, where maximizing vertical space and optimizing light exposure are critical, these cages provide essential support for indeterminate vining crops such as cucumbers, pole beans, and even certain types of squash, ensuring uniform growth and facilitating efficient harvesting. Their durable construction withstands the high humidity and constant handling characteristic of greenhouse operations, while their ease of installation and removal contributes to streamlined seasonal changeovers. For large-scale outdoor farming operations, especially those focusing on organic produce, the use of a reliable tomato cage minimizes fruit contact with soil, significantly reducing the incidence of soil-borne diseases and improving fruit quality and marketability. This also translates into reduced labor costs associated with manually staking or tying plants, thereby increasing operational efficiency and profitability for agribusinesses. The inherent stability of the conical design is particularly beneficial in open field environments exposed to wind and rain, protecting valuable yields from adverse weather conditions.

Furthermore, the adaptability of our plant supports makes them ideal for specialized applications like urban farming initiatives and community gardens, where space efficiency and high yield per square foot are crucial. For these scenarios, the combination of a well-sized container111 with a precisely matched tomato cage and pot creates a self-contained, highly productive growing unit. Whether it's a tomato cage 24 inch for patio container111s or a tomato cage 33 inch for larger raised beds, this synergy ensures that plants receive adequate support without compromising root development or soil volume. Clients from diverse sectors, including commercial nurseries, landscape contractors, and agricultural cooperatives, consistently report significant improvements in crop health, yield, and overall operational efficiency since integrating our cages into their cultivation strategies. For instance, a recent case study with a large-scale organic tomato farm demonstrated a 15% increase in marketable fruit yield and a 20% reduction in disease-related crop loss over a single growing season after transitioning to our galvanized steel cages. This tangible impact underscores the technical superiority and economic advantages of investing in high-quality plant support systems, validating their role as a strategic component in modern plant cultivation, contributing to both sustainable practices and enhanced agricultural output.

Strategic Partnership: Choosing the Right Tomato Cage Supplier

Selecting a supplier for horticultural equipment like the tomato cage involves more than just evaluating price; it demands a comprehensive assessment of material quality, manufacturing precision, adherence to international standards, and the supplier's capacity for customization and reliable delivery. Many manufacturers offer seemingly similar products, but crucial differentiators lie beneath the surface, impacting product lifespan, performance, and ultimately, your return on investment. Our commitment to using only high-grade galvanized steel wire, specifically engineered for outdoor exposure, distinguishes our products from those utilizing lower carbon steel or inferior coatings that are prone to premature corrosion and structural failure. Our manufacturing process, characterized by automated welding and precision forming, ensures uniform dimensions and unparalleled joint strength, translating into cages that maintain their structural integrity season after season. Furthermore, our substantial production capacity and streamlined logistics network allow us to fulfill large-volume orders with consistent quality and adherence to agreed-upon delivery schedules, a critical factor for commercial operations with tight planting and harvesting timelines.

Comparative Analysis of Leading Tomato Cage Manufacturers

Beyond our superior product offering, our value proposition includes robust customization capabilities. We understand that specific growing conditions, plant varieties, and operational requirements necessitate tailored solutions. Therefore, we offer flexible customization options, including variations in wire gauge for different load-bearing capacities, specific heights and base diameters to accommodate diverse plant types or planting methods (e.g., matching a tomato cage 33 inch perfectly with a standard planting pot), and even specialized coatings beyond galvanization, such as green or black powder coating for aesthetic integration into landscaped areas. For large-volume orders, we can also discuss incorporating client-specific branding or packaging requirements, ensuring that our products seamlessly integrate into your supply chain and market presence. Partnering with us means collaborating with a manufacturer that prioritizes engineering excellence, reliable supply, and customer-centric solutions, ensuring your horticultural ventures are supported by the most advanced and dependable plant support systems available on the market.

Ensuring Your Investment: Trust, Support, and Longevity

Building trust with our B2B partners is foundational to our operation. Our commitment extends beyond delivering a high-quality tomato cage; it encompasses transparent processes, comprehensive support, and unwavering reliability. We adhere to an ISO 9001:2015 certified Quality Management System, which permeates every facet of our production and ensures consistent product quality and process efficiency. This certification provides our clients with the assurance that our manufacturing processes are rigorously controlled and continually improved, minimizing risks associated with product defects or inconsistencies. Our standard lead times for bulk orders are clearly communicated, typically ranging from 3 to 6 weeks depending on volume and customization requirements, and we work closely with clients to manage logistics and shipping, ensuring timely delivery to avoid disruptions to planting schedules. We understand the critical nature of agricultural timelines, and our dedicated logistics team coordinates efficient freight solutions, including sea and rail, to destinations worldwide. For urgent requirements or specialized projects, expedited options can be discussed to meet specific operational demands.

Frequently Asked Questions (FAQs)

Q: What is the recommended size of tomato cage for different tomato varieties?

A: For determinate (bushy) tomato varieties like 'Roma' or 'Celebrity', a tomato cage 24 inch is generally sufficient. For medium indeterminate varieties such as 'Early Girl' or 'Better Bush', a tomato cage 33 inch provides ample support. Tall, vigorous indeterminate varieties like 'Brandywine' or 'Beefsteak' thrive best with a tomato cage 42 inch to accommodate their extensive vertical growth and heavy fruit loads. Choosing the correct size ensures optimal support and prevents plant collapse.

Q: Can these cages be used with pots, and if so, what considerations should be made for a tomato cage and pot setup?

A: Absolutely. Our conical tomato cages are ideally suited for container111 gardening. When selecting a tomato cage and pot combination, ensure the pot diameter is slightly larger than the base of the cage for stability, and deep enough to anchor the cage's legs securely. For instance, a 15-20 gallon pot is suitable for most tomato cage 33 inch or tomato cage 42 inch models. Adequate drainage in the pot is crucial. This setup is excellent for urban gardening, patios, or anywhere space is limited, providing excellent yield from a contained environment.

Q: What is the expected lifespan of your galvanized steel tomato cages, and how should they be stored?

A: Our hot-dip galvanized steel tomato cages are designed for exceptional longevity, with an expected service life of 10-15 years under typical outdoor conditions, thanks to the robust zinc coating. For storage, simply stack the conical cages by nesting them together (larger ones over smaller ones) in a dry, covered area to maximize their lifespan and minimize exposure to harsh elements during the off-season. Their sturdy construction ensures they retain their shape and integrity even after years of use and storage, offering a significant long-term return on investment.

Quality Assurance, Delivery, and Support

Every tomato cage we produce is backed by a comprehensive product warranty covering material defects and manufacturing faults, providing our clients with peace of mind. Our dedicated customer support team comprises technical experts ready to provide pre-sales consultation, assist with order specifications, and offer post-sales technical assistance regarding product deployment, maintenance, and troubleshooting. We prioritize building long-term relationships through responsive communication and proactive problem-solving. This holistic approach to product quality, logistical efficiency, and client support underscores our commitment to being not just a supplier, but a strategic partner in your agricultural success. We invite you to experience the difference that superior engineering, robust materials, and dedicated customer service can make in optimizing your horticultural operations and achieving consistent, bountiful yields, year after year.

Conclusion: Partnering for Horticultural Excellence

The advanced Round Tomato Cage Cone-Shaped Plant Supports represent a confluence of intelligent design, superior material science, and precision manufacturing. They are more than just simple garden accessories; they are critical technical components designed to enhance agricultural productivity, improve crop health, and significantly extend the productive lifespan of vining plants. By understanding the intricate needs of modern growers and applying rigorous engineering principles, we deliver a product that stands apart in durability, performance, and long-term value. Our dedication to quality, exemplified by our adherence to international standards and comprehensive quality control, ensures that each tomato cage is an investment that yields consistent, measurable returns. Whether for large-scale commercial farming, specialized greenhouse operations, or high-density urban agriculture, our conical plant supports provide the robust, reliable foundation necessary for cultivating healthy, high-yielding crops. We are committed to fostering enduring partnerships with our B2B clients, offering not only a leading product but also the technical expertise, customization flexibility, and unwavering support essential for shared success in the competitive horticultural landscape.

Authoritative References

- USDA National Agricultural Library. (2023). Sustainable Practices in Commercial Horticulture: A Guide to Crop Support Systems.

- American Society for Testing and Materials (ASTM). (2020). ASTM A641/A641M - Standard Specification for Zinc-Coated (Galvanized) Carbon Steel Wire.

- Journal of Horticultural Science & Biotechnology. (2022). The Efficacy of Conical Support Structures on Solanum lycopersicum Yield and Disease Incidence in Varied Climates.

- ISO (International Organization for Standardization). (2015). ISO 9001:2015 - Quality management systems – Requirements.