Industry Trends and the Strategic Importance of Pond Fencing Solutions

The demand for robust and aesthetically integrated protective solutions around water features, particularly koi ponds, is experiencing significant growth in commercial and industrial landscaping. A well-designed koi pond fence is no longer merely a safety measure but a critical component in site planning, offering both functional security and enhanced visual appeal. Modern trends emphasize durable materials, modular designs, and customization options that align with sophisticated architectural and landscape requirements. This shift is driven by increased regulatory scrutiny concerning public safety, heightened awareness of asset protection (valuable koi fish and pond equipment), and a desire for low-maintenance, long-lasting installations.

Key industry trends include the integration of smart fencing technologies, such as motion sensors and discreet lighting, though the core focus remains on the structural integrity and material science. There is a growing preference for materials that offer superior corrosion resistance and minimal environmental impact, ensuring a prolonged service life with reduced maintenance overhead. Businesses, from hospitality venues to corporate campuses and public parks, are increasingly investing in sophisticated fencing across a pond to mitigate risks and elevate their property's perceived value. The market is evolving towards solutions that are not only compliant with safety standards but also contribute positively to the overall ecological balance and aesthetic harmony of the water feature.

Manufacturing Process and Technical Specifications

Detailed Process Flow: From Raw Material to Finished koi pond fence

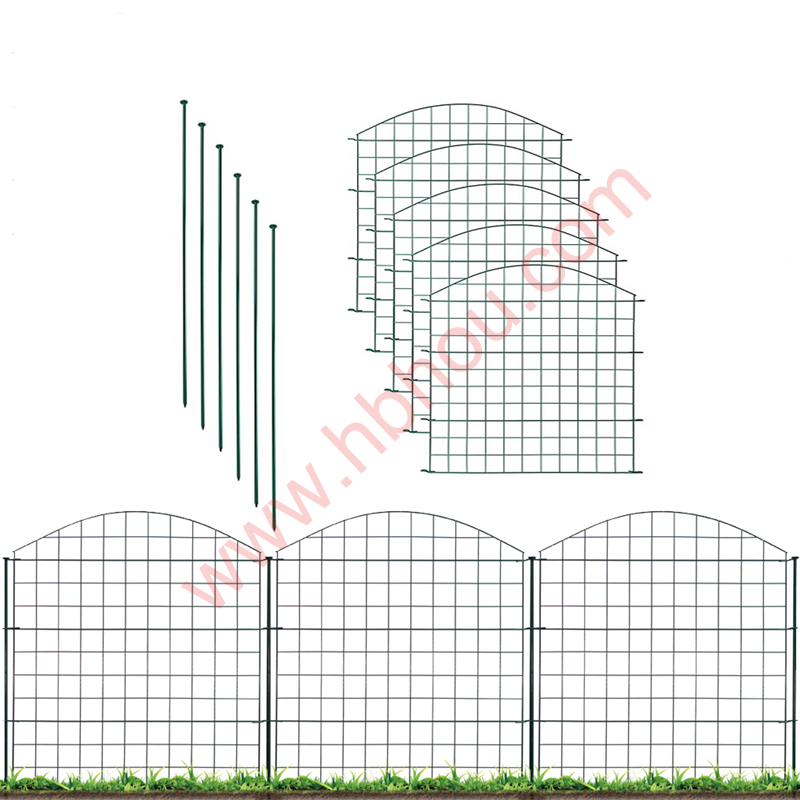

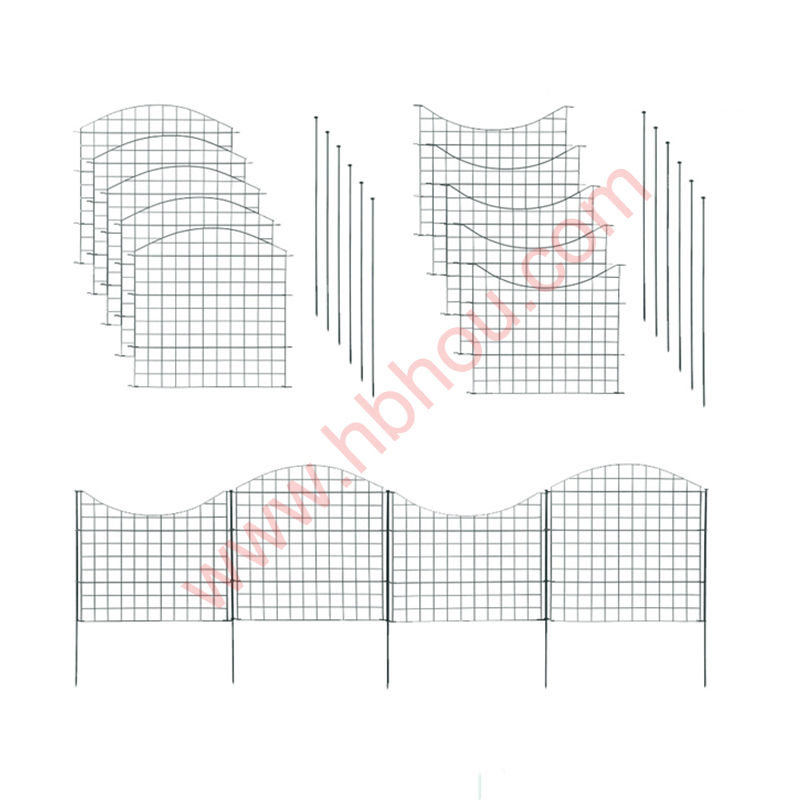

The manufacturing of high-quality pond fencing involves a meticulous, multi-stage process designed to ensure durability, structural integrity, and aesthetic appeal. Our Garden Pond Fence Border is a prime example, utilizing advanced techniques to meet stringent industry standards.

- Material Selection and Preparation: We primarily utilize high-grade galvanized steel or durable wrought iron, known for its tensile strength (e.g., typically 300-400 MPa for galvanized steel) and inherent resistance to environmental stressors. Raw materials undergo rigorous inspection to meet chemical composition and mechanical property standards, often conforming to ASTM A653 for galvanized steel.

- Precision Cutting and Shaping: Using CNC machining, steel or iron rods are precisely cut to the required lengths and shapes. This ensures uniform dimensions and tight tolerances, critical for modular assembly. This stage often includes laser cutting for intricate designs, providing superior edge quality.

- Welding and Assembly: Components are assembled and welded using advanced robotic MIG (Metal Inert Gas) or TIG (Tungsten Inert Gas) welding techniques. This creates strong, seamless joints that can withstand significant impact and environmental stresses, ensuring the longevity of the fenced in pond structure. All welds are inspected for penetration and absence of defects.

-

Surface Treatment (Galvanization & Powder Coating):

- Hot-Dip Galvanization: After fabrication, components are hot-dip galvanized, applying a protective zinc coating (typically 600 g/m² or 2.0 oz/ft² on average for heavy-duty applications, per ASTM A123) that forms an metallurgical bond with the steel, providing cathodic protection against corrosion. This process extends service life significantly, often beyond 20 years in outdoor environments.

- Powder Coating: Following galvanization, components undergo a multi-stage cleaning and pre-treatment process before being electrostatically powder coated. This adds a durable, UV-resistant layer that enhances aesthetic appeal and provides a second layer of corrosion protection. The powder coat typically meets or exceeds ASTM D3451 standards for film thickness (e.g., 60-100 microns) and adhesion.

- Quality Control and Testing: Each batch undergoes rigorous testing, including salt spray testing (ASTM B117, typically for 1000+ hours), impact resistance (ASTM D2794), and adhesion tests. Dimensional accuracy, weld integrity, and coating thickness are meticulously checked to ensure compliance with ISO 9001 and ANSI standards, guaranteeing consistent product quality.

- Packaging and Dispatch: Finished pond fence panels are carefully packed to prevent damage during transit, ensuring they arrive on-site in pristine condition.

Product Specification Table: Garden Pond Fence Border

Application Scenarios and Technical Advantages

Target Industries and Enhanced Safety

The versatility and robust construction of our koi pond fence solutions make them indispensable across a broad spectrum of B2B applications. Target industries include:

- Hospitality & Resorts: Securing decorative ponds and water features in hotel gardens, golf courses, and resort grounds, preventing accidental falls by guests, especially children.

- Commercial & Corporate Campuses: Enhancing the safety perimeter around water landscaping, protecting employees and visitors, while maintaining an elegant aesthetic.

- Public Parks & Municipalities: Providing essential safety barriers for public ponds, ensuring compliance with local safety ordinances and reducing liability risks. This includes fencing across a pond in high-traffic areas.

- Aquaculture & Zoos: Protecting valuable aquatic life from external predators or human interference, and safeguarding visitors from potential water hazards. A robust fence around pond installations is crucial here.

- Residential Developments (HOAs): Offering communal safety solutions for shared water features within planned communities.

Technical Advantages in Typical Application Scenarios

- Superior Corrosion Resistance: The dual-layer protection of hot-dip galvanization and UV-resistant powder coating ensures exceptional longevity even in harsh, moist environments typical of pond surroundings. This significantly reduces the total cost of ownership (TCO) by minimizing the need for frequent repairs or replacements, distinguishing our products from conventional painted fences. This makes our fencing ideal for areas exposed to constant moisture or chemical treatments often found in pond maintenance.

- Robust Structural Integrity: Engineered with precision-welded joints and high-strength materials, our fences provide a formidable barrier. They are designed to withstand significant impacts and environmental forces, including high winds (rated for speeds up to 120 km/h with proper installation), ensuring reliable containment and safety. This structural resilience is crucial for public safety and the protection of valuable aquatic assets in a fenced in pond.

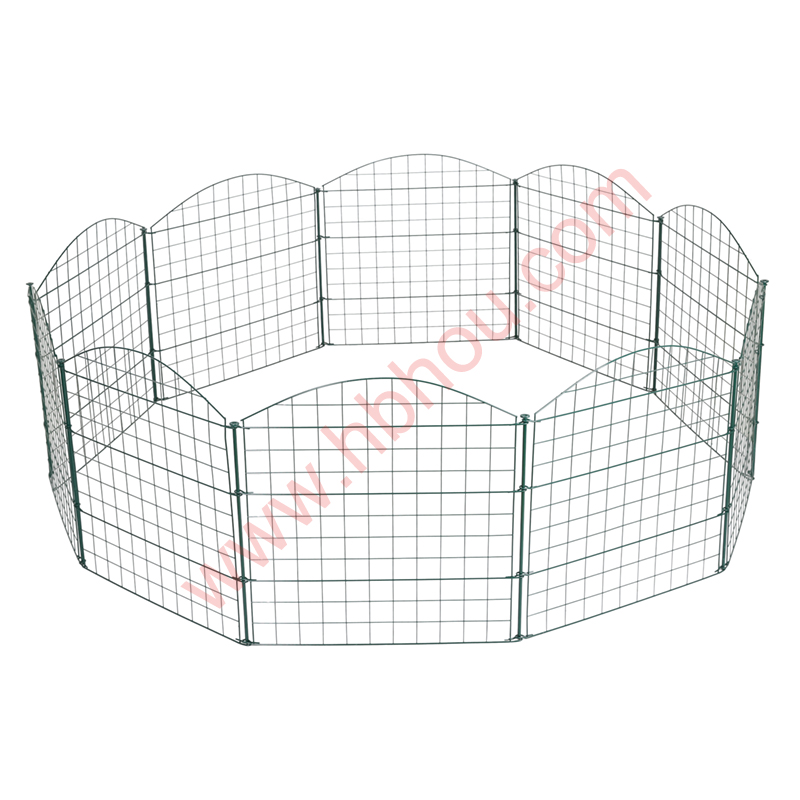

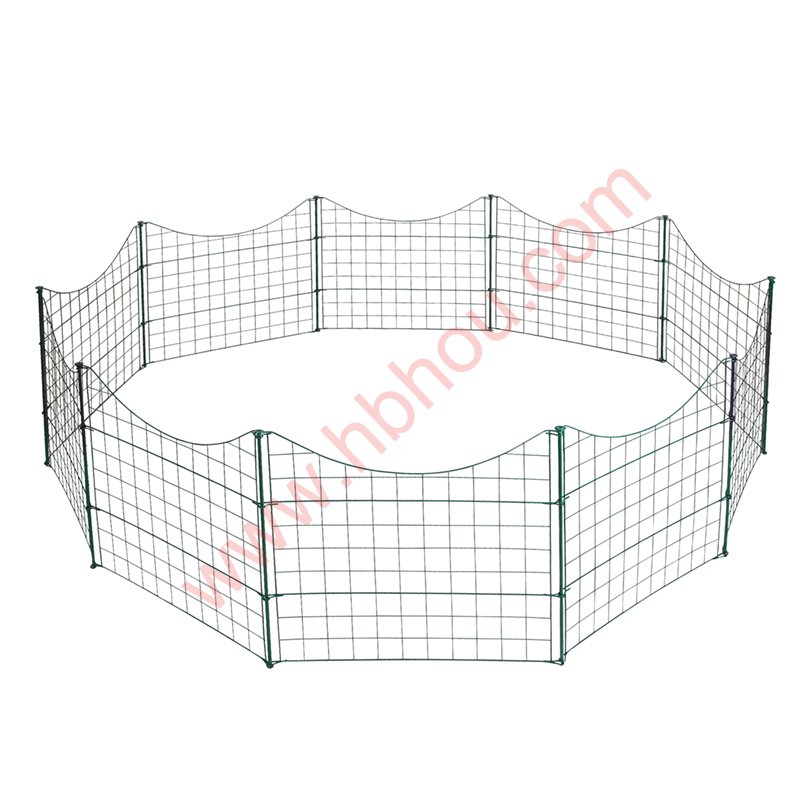

- Aesthetic Integration: Beyond mere functionality, the sophisticated designs and customizable finishes (e.g., various RAL colors, decorative finials) allow seamless integration with diverse architectural styles and landscape designs. This enhances the overall visual appeal of the property, adding to its value rather than detracting from it. The modular design also allows for elegant curves and contours, complementing natural pond shapes.

- Low Maintenance & Extended Service Life: The advanced coating systems dramatically reduce the need for routine painting or rust treatment. A simple periodic cleaning is often sufficient to maintain its pristine appearance and protective qualities. With an estimated service life exceeding 20 years, our solutions offer exceptional long-term value.

- Energy Saving (Indirect): While not directly an energy-saving component, a well-placed and robust fence around pond features can indirectly contribute. By establishing a clear, secure perimeter, it can deter unauthorized access which might lead to damage to pond infrastructure (pumps, filters, lighting), thus preventing costly repairs or premature equipment replacement that consume energy. Furthermore, in certain configurations, a fence can act as a windbreak, potentially reducing evaporative heat loss from heated ponds, thus slightly lowering energy consumption for heating systems.

Vendor Comparison and Customized Solutions

Comparative Analysis of koi pond fence Offerings

When selecting a fencing solution for aquatic environments, B2B decision-makers evaluate various factors beyond initial cost. Our offerings are meticulously designed to provide superior performance, longevity, and aesthetic value compared to conventional options. The table below highlights key differentiators:

Customized Solutions for Unique Project Requirements

Recognizing that every B2B project presents unique challenges, we specialize in providing tailored fencing solutions. Our engineering and design teams collaborate closely with clients to develop a pond fence that perfectly integrates with specific site conditions, aesthetic visions, and functional demands.

- Design Customization: From decorative finials and wrought iron scrollwork to modern minimalist panels, we can match any architectural style. We offer CAD renderings and 3D modeling to visualize the final product.

- Material & Finish Options: While galvanized steel is standard, we can explore marine-grade aluminum for extremely corrosive environments or custom alloys based on project specifications. A vast palette of RAL powder coating colors is available for precise brand or landscape matching.

- Dimensions & Configuration: Custom heights, panel widths, and post spacing can be engineered to meet specific safety codes or aesthetic requirements. Solutions for undulating terrain or complex pond shapes, including curved fence sections, are routinely provided.

- Integrated Features: Custom gates (pedestrian, vehicular, or emergency access), smart access control systems, integrated LED lighting, and security camera mounts can be seamlessly incorporated into the fence design.

- Installation Adaptations: Whether deep embedment for maximum wind resistance, surface-mounted flange posts for hardscapes, or unique mounting solutions for irregular surfaces, our team ensures practical and robust installation methods.

Application Case Studies & Customer Feedback

Case Study 1: Luxury Resort Water Garden Fencing

A prominent luxury resort in a coastal region required a sophisticated fence around pond features that would enhance guest safety without compromising the opulent aesthetic of their award-winning water gardens. The challenge was to install a durable fencing solution capable of withstanding saltwater exposure and high humidity while seamlessly blending with the existing landscape.

- Solution Provided: We engineered a bespoke koi pond fence system using marine-grade galvanized steel, followed by a specialized two-part epoxy and powder coat finish in a custom bronze tone. The design incorporated decorative paneling with subtle curvatures to follow the natural contours of the ponds and integrated discreet, low-voltage LED pathway lighting. Installation involved direct embedment for maximum stability against strong coastal winds.

- Results: The installation was completed within budget and ahead of schedule. Post-installation inspections confirmed robust structural integrity and exceptional resistance to the corrosive coastal environment. The resort reported a significant enhancement in guest safety, particularly concerning children, and received positive feedback on the elegant integration of the fence with the garden’s aesthetics. The maintenance team noted a drastic reduction in required upkeep compared to previous fencing solutions.

- Client Feedback: "The quality and design of the pond fence exceeded our expectations. It provides the essential safety we needed while maintaining the luxurious feel of our gardens. The durability in our coastal climate has been remarkable." - *Facilities Manager, Coastal Luxury Resort.*

Case Study 2: Public Park Pond Rehabilitation Project

A municipal park undertook a major rehabilitation of its central pond, a popular public gathering spot. The project necessitated a durable and child-safe fenced in pond solution to meet stringent public safety regulations while being visually unobtrusive.

- Solution Provided: We supplied a modular galvanized steel fence around pond sections, featuring tightly spaced vertical pickets to prevent children from climbing through. The fence was finished with a dark green powder coat, chosen to blend naturally with the park's foliage. Robust hinge and latch mechanisms were integrated into strategically placed access gates, meeting ADA compliance.

- Results: The new fencing dramatically improved safety for park visitors, especially families. The modular design facilitated rapid installation, minimizing disruption to public access. The durable coating ensured resistance to vandalism and weathering. The park management lauded the ease of maintenance and the fence’s ability to withstand heavy public use.

- Client Feedback: "Our primary concern was public safety, and this pond fence delivered. Its robust construction and low-profile design were perfect for our park environment. We appreciate the technical support during planning and installation." - *Director of Parks & Recreation, City Municipality.*

These case studies underscore our commitment to delivering expert, experience-backed, and authoritative solutions for complex B2B fencing requirements around water bodies. Our continuous focus on material science and engineering excellence ensures product reliability that clients can trust for decades.

Trustworthiness & Support: FAQs, Lead Time, Warranty, and After-Sales

Frequently Asked Questions (FAQ)

Q1: What is the typical lead time for a customized koi pond fence order?

A1: Standard modular orders typically ship within 2-4 weeks. For fully customized solutions, lead times can range from 6-12 weeks, depending on design complexity, material sourcing, and order volume. We provide a detailed project timeline upon order confirmation.

Q2: What kind of warranty do you offer on your pond fencing products?

A2: We offer a comprehensive 10-year limited warranty on material defects and coating adhesion under normal use and proper installation. This covers against cracking, peeling, or significant fading of the powder coat and structural integrity of the galvanized steel. Specific terms and conditions are provided with each quotation.

Q3: Can your fencing solutions be installed on uneven terrain or around irregularly shaped ponds?

A3: Yes, our modular designs and custom fabrication capabilities allow for adaptable installation on various terrains. Our engineering team can design stepped or raked fence sections and create custom curved panels to precisely follow irregular pond perimeters, ensuring a seamless and secure fence around pond features.

Q4: What maintenance is required for your galvanized and powder-coated fences?

A4: Due to the superior corrosion resistance of our dual-layer coating, maintenance is minimal. Regular cleaning with mild soap and water is recommended to remove dirt and debris. Avoid abrasive cleaners or harsh chemicals that could damage the finish. Periodic inspection for any signs of damage is also advised, though repairs are rare.

Lead Time and Fulfillment Details

Our streamlined production process and robust supply chain are optimized for efficiency. Once an order is confirmed, clients receive a detailed project schedule including design finalization, manufacturing, quality control, and shipping estimates. We pride ourselves on transparent communication and proactive updates throughout the fulfillment process. Expedited manufacturing and shipping options are available for urgent projects, subject to capacity and material availability. All products are crated and secured for international or domestic freight, ensuring safe delivery to your site.

Comprehensive Warranty Commitments

Our commitment to quality is underscored by our robust warranty policy. The 10-year limited warranty reflects our confidence in the materials and manufacturing processes employed for every product, including our pond fence solutions. This warranty protects your investment and provides peace of mind, knowing that your fencing solution is backed by an authoritative manufacturer dedicated to durability and performance. We adhere to stringent ISO 9001 quality management standards in every step of our operation.

Dedicated Customer Support and After-Sales Service

Our relationship with clients extends well beyond the point of sale. We offer dedicated technical support, assisting with installation guidelines, troubleshooting, and maintenance best practices. Our after-sales service team is readily available to address any inquiries or concerns, ensuring continuous satisfaction and optimal product performance throughout its extensive service life. We also provide replacement parts and repair guidance if accidental damage occurs.

Conclusion

Investing in a high-quality koi pond fence is a strategic decision for any B2B entity managing commercial, public, or high-value aquatic landscapes. Our advanced galvanized and powder-coated steel fencing solutions offer an unparalleled combination of safety, durability, aesthetic appeal, and low total cost of ownership. By leveraging precision manufacturing, adherence to international standards, and a deep understanding of industry-specific challenges, we deliver products that not only meet but exceed client expectations. From mitigating liability and protecting valuable assets to enhancing property aesthetics, our fencing systems provide a reliable and long-lasting solution for any fenced in pond requirement.

References

- American Society for Testing and Materials (ASTM). "ASTM A123/A123M - 17, Standard Specification for Zinc (Hot-Dip Galvanized) Coatings on Iron and Steel Products." ASTM International, 2017.

- International Organization for Standardization (ISO). "ISO 9001:2015 - Quality management systems – Requirements." ISO, 2015.

- American Society of Civil Engineers (ASCE). "ASCE/SEI 7-16 Minimum Design Loads and Associated Criteria for Buildings and Other Structures." ASCE, 2016.

- NACE International. "Corrosion Basics: An Introduction." NACE International, 2012.

- Powder Coating Institute (PCI). "Powder Coating: The Complete Finisher's Handbook." PCI, 2020.