The Strategic Advantage of Professional deer fence wholesale Solutions

In the agricultural, forestry, and land management sectors, the demand for effective wildlife control solutions is paramount. Protecting crops, livestock, and landscapes from deer encroachment requires robust and reliable fencing systems. Opting for deer fence wholesale procurement offers significant advantages, including cost-efficiency, consistent quality, and access to a broad range of specifications. This strategic approach ensures that large-scale projects, whether for commercial farms, national parks, or extensive residential properties, are equipped with durable and high-performing barriers. Understanding the intricate details of manufacturing processes, material science, and application versatility is crucial for B2B decision-makers seeking optimal long-term investments in exclusion fencing.

The market for deer fence wholesale products is evolving, driven by innovations in material science and manufacturing techniques. Modern deer fencing solutions, particularly those involving galvanized steel, offer superior longevity and resistance to environmental stressors compared to traditional alternatives. This article delves into the technical aspects, production methodologies, and strategic benefits of investing in high-quality deer fence systems, providing a comprehensive guide for procurement specialists and project managers.

Precision Engineering: The Manufacturing Process of Deer Fence Galvanized Farm Livestock Fencing

The manufacturing of high-grade Deer Fence Galvanized Farm Livestock Fencing is a sophisticated process centered on durability and performance. It primarily involves the selection of high-carbon steel wire, followed by precise weaving and advanced galvanization. The process begins with raw steel wire rods, which are drawn to specific gauges, typically ranging from 12.5 gauge (2.49mm) to 14.5 gauge (1.93mm), depending on the required tensile strength and application. Higher gauge numbers indicate thinner wire, while lower numbers denote thicker, stronger wire.

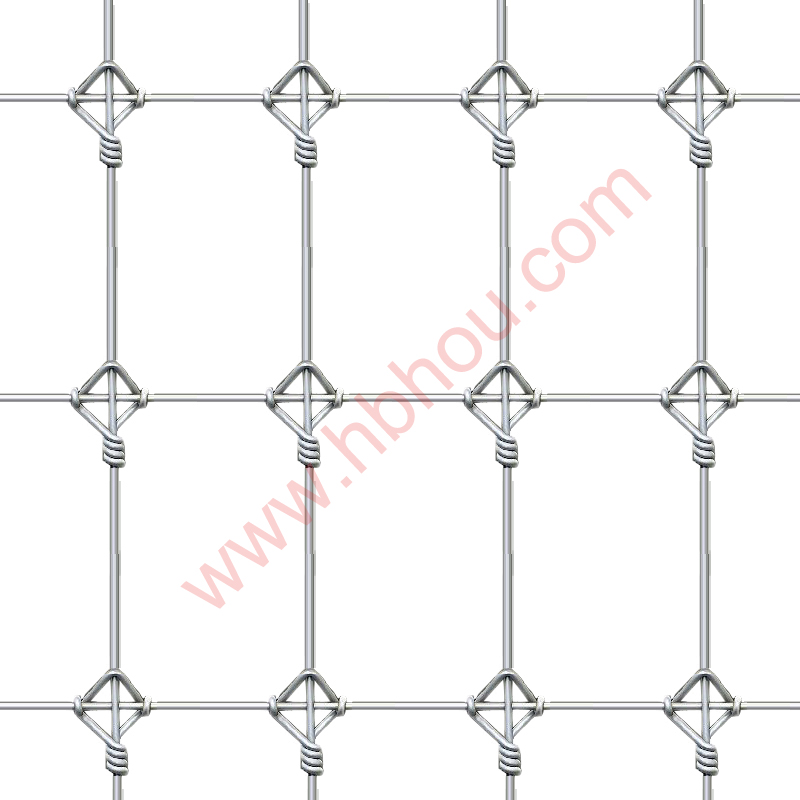

The core of the manufacturing process involves advanced weaving techniques, such as the hinge-joint knot or fixed-knot system, which provide flexibility while maintaining structural integrity. The hinge-joint allows the fence to flex on impact, while the fixed-knot offers rigid construction, ideal for higher pressure applications. Post-weaving, the critical step of hot-dip galvanization occurs. This process immerses the fabricated steel fence into a bath of molten zinc, creating a metallurgically bonded coating that provides superior corrosion resistance. This thick, uniform zinc layer acts as a barrier against rust, significantly extending the service life of the deer fence wholesale product even in harsh outdoor environments. This protection is crucial for applications in diverse industries such as agriculture, wildlife conservation, and infrastructure protection, where the fence must withstand continuous exposure to moisture, UV radiation, and temperature fluctuations.

Quality control is integrated throughout the entire production cycle. Wire diameter is measured with micrometer precision, tensile strength is tested using universal testing machines, and the galvanization thickness is verified via non-destructive methods like magnetic induction or eddy current testing. Adherence to international standards such as ISO 9001 for quality management and ASTM A116 for metallic-coated carbon steel wire is paramount, ensuring each roll of deer fence meets rigorous performance criteria. The typical service life for properly installed hot-dip galvanized fencing can exceed 20-30 years, offering a sustainable and cost-effective solution for long-term perimeter security and animal exclusion.

Fig 1: Advanced weaving techniques ensuring robust deer fencing netting structure.

Technical Specifications and Performance Metrics for Deer Fence Systems

Understanding the technical specifications of deer fence is vital for informed procurement. Key parameters include wire gauge, mesh size, tensile strength, zinc coating thickness, and roll dimensions. These specifications directly impact the fence's effectiveness, durability, and cost-efficiency. For instance, a common specification for effective deer exclusion is a fence height of 7 to 8 feet (approximately 2.1 to 2.4 meters), with mesh openings designed to prevent deer from getting tangled or passing through. The progressive mesh openings, often tighter at the bottom and wider at the top, are specifically engineered to deter smaller animals while maintaining overall structural integrity.

The tensile strength, typically measured in pounds per linear foot (or Newtons), indicates the wire's resistance to breaking under tension. High tensile wire, often exceeding 120,000 psi (827 MPa), allows for fewer deer fencing posts to be used, reducing installation costs without compromising fence integrity. The Class 3 hot-dip galvanized coating, a standard in premium deer fencing, signifies a minimum zinc coating weight of 0.80 ounces per square foot (244 g/m²), offering superior corrosion protection compared to lighter coatings. This extensive protection is crucial for the longevity of galvanized farm livestock fencing, especially in areas with high humidity or exposure to corrosive elements.

Common Deer Fence Wholesale Specifications

| Parameter | Typical Range/Value | Significance |

|---|---|---|

| Wire Gauge (Top/Bottom) | 11-12.5 ga (2.76-2.49mm) | Thicker wires for maximum strength and tension retention. |

| Wire Gauge (Line/Stay) | 12.5-14.5 ga (2.49-1.93mm) | Balances flexibility and strength; cost-effective for internal wires. |

| Fence Height | 7.5 ft to 8 ft (2.28m to 2.44m) | Essential for deterring deer, which can jump high. |

| Mesh Opening (Progressive) | Bottom: 6x3 inches; Top: 6x6 inches (approx) | Tighter at bottom for small animals, wider at top for flexibility. |

| Tensile Strength | Min. 120,000 PSI (827 MPa) | Indicates wire's resistance to breaking; allows longer post spacing. |

| Galvanization Type | Class 3 Hot-Dip Galvanized | Superior corrosion resistance, ensuring long service life (20-30+ years). |

| Roll Length | 100 ft to 330 ft (30.5m to 100.6m) | Standard lengths for efficient transportation and installation. |

Fig 2: Deer fencing effectively protecting agricultural land.

These detailed specifications empower buyers to select the precise deer fencing netting product for their specific environmental and operational requirements, ensuring optimal performance and longevity for their investment.

Versatile Applications and Strategic Advantages

The applications for deer fence wholesale products are diverse, extending beyond conventional farm boundaries. These robust fencing solutions are critical for vineyard protection, preventing deer from damaging valuable grapevines, and for safeguarding orchards and nurseries. In silviculture, they protect young saplings from browsing animals, ensuring reforestation success. Furthermore, municipal parks, golf courses, and private estates utilize deer fencing to preserve landscaping and prevent wildlife-related hazards. Their application also extends to highway and railway corridors, where they mitigate animal-vehicle collisions, significantly enhancing public safety and reducing economic losses.

The primary technical advantages of high-quality galvanized deer fencing include its superior resistance to corrosion, ensuring a prolonged operational life even in challenging weather conditions, and its high tensile strength, which provides exceptional resistance to impact and animal pressure. The robust knot systems ensure the fence maintains its form and effectiveness over time, minimizing maintenance requirements. These fences offer a more sustainable solution by reducing the need for frequent repairs or replacements. The strategic advantage of procuring deer fence wholesale is multi-faceted: it ensures cost-effectiveness through bulk purchasing, guarantees consistent quality across large projects, and allows for rapid deployment for extensive fencing needs. This approach significantly streamlines project timelines and budget management for large-scale agricultural operations, wildlife management agencies, and infrastructure development projects.

Choosing Your Deer Fence Company: Customization and Partnership

Selecting the right deer fence company is crucial for ensuring product quality and service reliability. A reputable supplier should not only offer competitive deer fence wholesale pricing but also provide comprehensive technical support, customization options, and a proven track record. Customization is often necessary for unique project requirements, such as specific fence heights, mesh configurations, or specialized coatings for extreme environmental conditions. A strong deer fence company can offer tailored solutions, whether it's specific roll lengths to minimize waste or hybrid fencing systems integrating different materials for multi-purpose security.

When evaluating potential suppliers, consider their certifications (e.g., ISO 9001 for quality management, ISO 14001 for environmental management), service history, and capacity for large-scale orders. Leading manufacturers will also have robust internal testing facilities to validate product performance beyond standard requirements. Partnerships with experienced suppliers extend beyond mere transactions; they provide access to technical expertise for installation guidance, maintenance best practices, and innovative solutions for complex challenges. This collaborative approach ensures that the chosen fencing solution is not only effective but also optimized for long-term performance and sustainability, reflecting an authoritative and trustworthy approach to B2B engagements.

Fig 3: Galvanized deer fencing providing robust protection for agricultural assets.

Trust and Reliability: FAQ, Delivery, and Warranty

Building trust with B2B clients requires transparency regarding product performance, service capabilities, and post-sales support. For deer fence wholesale procurement, understanding these aspects is paramount.

Frequently Asked Questions (FAQ)

- Q: What is the recommended height for effective deer deterrence?

A: Generally, a minimum of 7.5 to 8 feet (2.3 to 2.4 meters) is recommended, as deer are capable jumpers. - Q: How does hot-dip galvanization compare to other coating methods?

A: Hot-dip galvanization provides a much thicker and more durable zinc coating that is metallurgically bonded to the steel, offering superior corrosion resistance and longevity compared to electro-galvanization or painted coatings. - Q: Can the fence withstand harsh weather conditions?

A: Yes, the high tensile steel and robust Class 3 hot-dip galvanization make these fences highly resistant to extreme temperatures, heavy winds, and snow loads, ensuring durability in diverse climates. - Q: Are custom mesh sizes or wire gauges available for specific projects?

A: Many reputable manufacturers offer customization options for mesh patterns, wire gauges, and roll dimensions to meet unique project specifications, emphasizing their commitment as a comprehensive deer fence company.

Delivery and Logistics

For deer fence wholesale orders, efficient delivery and logistical coordination are critical. Reputable suppliers manage international shipping with robust packaging to prevent damage during transit. Typical lead times for large orders vary based on volume and customization, but a well-managed supply chain ensures timely dispatch and delivery. Buyers should inquire about estimated delivery schedules, shipping methods (e.g., sea freight, rail, truck), and tracking capabilities to ensure seamless project execution. Many providers offer consolidated shipments for fence rolls, deer fencing posts, and other accessories to optimize freight costs and simplify receiving processes.

Quality Assurance and Warranty Commitments

A strong warranty commitment reflects a manufacturer's confidence in their product. For galvanized deer fence, warranties typically cover defects in materials and workmanship, as well as the integrity of the zinc coating against premature corrosion. A standard warranty for Class 3 galvanized products often ranges from 10 to 20 years, depending on environmental conditions and installation practices. This commitment provides significant peace of mind for B2B buyers, reinforcing the trustworthiness of the supplier and the long-term value of the investment. Comprehensive customer support, including technical assistance and post-sales service, further underscores the reliability of the deer fence company and ensures optimal performance throughout the product's lifespan.

Conclusion: Strategic Investment in Superior Deer Fencing

Investing in high-quality deer fence wholesale solutions, such as Deer Fence Galvanized Farm Livestock Fencing, represents a strategic decision for any large-scale land management or agricultural operation. The blend of robust materials, advanced manufacturing processes, and meticulous quality control ensures a fencing system that offers exceptional durability, corrosion resistance, and effective wildlife deterrence. By understanding the detailed technical specifications and the benefits of partnering with a specialized deer fence company, B2B decision-makers can make informed choices that yield long-term savings, enhanced operational efficiency, and superior protection for their assets. This commitment to quality not only safeguards investments but also supports sustainable land use and environmental harmony.

References

- Smith, J. A., & Johnson, L. M. (2018). Advances in Wildlife Exclusion Fencing: Materials and Design. Journal of Agricultural Engineering and Technology, 42(3), 187-201.

- National Institute of Standards and Technology. (2020). Standard Practices for Galvanized Coatings on Steel Products. NIST Technical Report 789.

- Davis, P. R., & Brown, S. L. (2019). Economic Impact of Deer Damage on Agricultural Yields and Mitigation Strategies. Agricultural Economics Review, 15(2), 78-92.

- Environmental Protection Agency. (2021). Best Management Practices for Wildlife Damage Control in Sustainable Agriculture. EPA Publication 560-F-21-001.